High molecular thin film dust suppressant in netty structure and preparation method thereof

A polymer film, network structure technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of ore powder loss, dust, pollution, ore powder scattering, etc., and achieve the effect of good film-forming characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

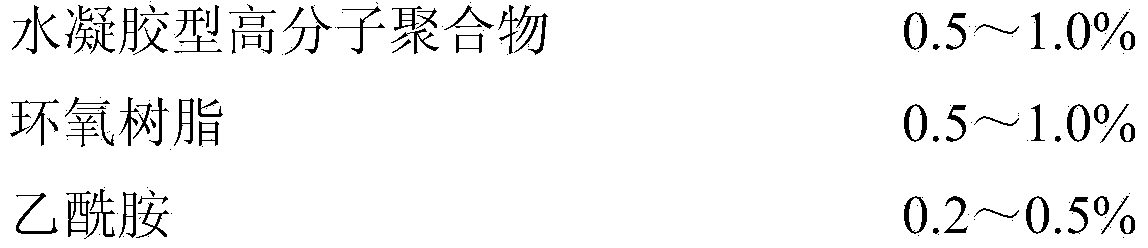

[0028] Take 0.6g of water-based epoxy resin (solid content 49-51%) (commercially available) and dissolve it in 98.33g of tap water. After fully dissolving, take 0.2g of acetamide and dissolve in the above solution, and then dissolve 0.8g of polyvinyl alcohol in In the above solution, 0.07 g of sodium stearate was dissolved in the above solution, and the mixture was fully stirred evenly to obtain a polymer film dust suppressant with a network structure.

Embodiment 2

[0030] Take 0.9g of water-based epoxy resin (solid content 55-56%) (commercially available) and dissolve it in 97.71g of tap water. After fully dissolving, take 0.3g of acetamide and dissolve it in the above solution, then dissolve 1.0g of polyacrylic acid in the above solution, and then 0.09g of sodium stearate was dissolved in the above solution, and fully stirred evenly to obtain a network structure polymer film dust suppressant.

Embodiment 3

[0032] Take 1.0g of water-based epoxy resin (solid content 50%) (commercially available) and dissolve it in 97.9g of tap water. After fully dissolving, take 0.5g of acetamide and dissolve it in the above solution, then dissolve 0.5g of polyvinylpyrrolidone in the above solution, and then dissolve 0.1g of sodium stearate in the above solution, fully stir evenly, and then obtain the polymer film dust suppressant with network structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com