Reversible duplex type fermentation equipment

The technology of fermentation equipment and rotating shaft is applied in the field of duplex fermentation equipment, which can solve the problems of high cost and complex structure, and achieve the effects of simple operation, wide practicability and improving fermentation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

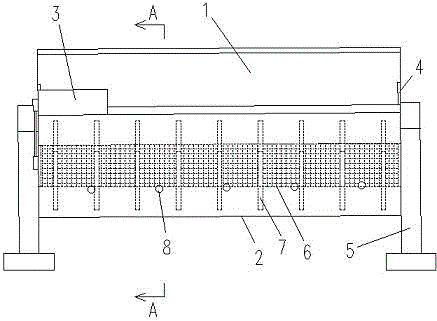

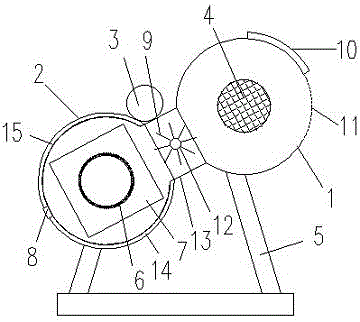

[0023] As a preferred embodiment of the present invention, please refer to figure 1 and 2 , with a first barrel 2 and a second barrel 1, the central axes of the first barrel 2 and the second barrel 1 form an included angle of 5-10 degrees with the horizontal plane.

[0024] The first barrel 2 and the second barrel 1 are connected by a transition cavity 13 in the shape of a cuboid. The two ends of the transition cavity 13 are respectively provided with brackets 5, and the brackets 5 are provided with flipping motors to control the entire fermentation equipment. flip operation.

[0025] The transition cavity 13 is provided with a rotating shaft 12, and several stirring rods 9 are arranged on the rotating shaft 12, which are used to transport materials from the first barrel 2 to the second barrel 1, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com