Coated copy paper and production method thereof

A production method and technology of copy paper, which is applied in the field of copy paper, can solve the problems that the service life of the toner cartridge of the copier is greatly affected, the copy clarity and copy effect are affected, and the surface smoothness of the copy paper is not high, so as to increase the added value and economic benefits , product performance refinement, and the effect of improving opacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

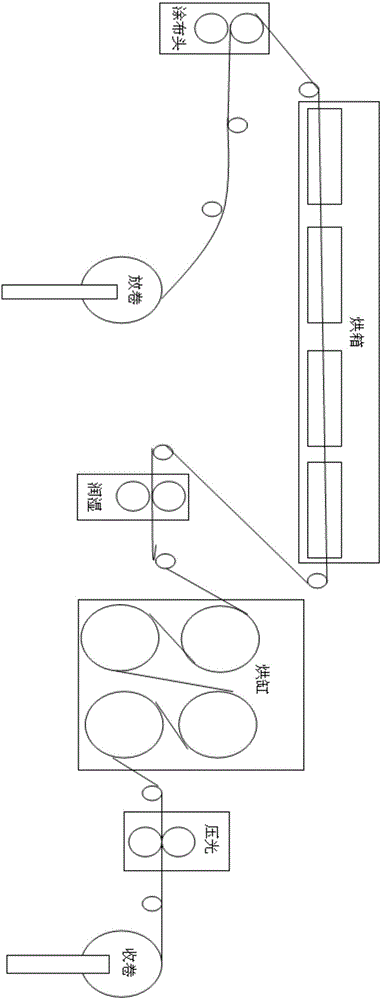

Image

Examples

Embodiment 1

[0052] A coated copy paper comprises a base paper layer and a coating layer coated on the surface of the base paper layer.

[0053] The coating is made by coating a coating material, and the coating material is made of components comprising the following parts by weight:

[0054] adhesive:

[0055] Carboxylated styrene-butadiene latex 2

[0056] Modified starch 2

[0057] CMC 2

[0058] PVA 2

[0059] Brightener:

[0060] Sodium hexasulfonate 0.2

[0061] Absorbent:

[0062] Ultrafine silica 3

[0063] Hollow microspheres 3

[0064] Titanium dioxide 3

[0065] filler:

[0066] CaCO 3 twenty one

[0067] Kaolin 21

[0068] Auxiliary:

[0069] Cationic color fixing agent 0.2

[0070] Non-ionic color fixing agent 0.2.

Embodiment 2

[0072] A coated copy paper comprises a base paper layer and a coating layer coated on the surface of the base paper layer.

[0073] The coating is made by coating a coating material, and the coating material is made of components comprising the following parts by weight:

[0074] adhesive:

[0075] Carboxylated styrene-butadiene latex 29

[0076] Modified starch 29

[0077] CMC 29

[0078] PVA 29

[0079] Brightener:

[0080] Sodium hexasulfonate 4.9

[0081] Absorbent:

[0082] Ultrafine silica 24

[0083] Hollow microspheres 24

[0084] Titanium dioxide 24

[0085] filler:

[0086] CaCO 3 59

[0087] Kaolin 59

[0088] Auxiliary:

[0089] Cationic color fixing agent 4.9

[0090] Non-ionic color fixing agent 4.9.

Embodiment 3

[0092] A coated copy paper comprises a base paper layer and a coating layer coated on the surface of the base paper layer.

[0093] The coating is made by coating a coating material, and the coating material is made of components comprising the following parts by weight:

[0094] adhesive:

[0095] Carboxylated styrene-butadiene latex 10-20

[0096] Modified starch 10-20

[0097] CMC 10-20

[0098] PVA 10-20

[0099] Brightener:

[0100] Sodium hexasulfonate 2-3

[0101] Absorbent:

[0102] Ultrafine silica 10-20

[0103] Hollow microspheres 10-20

[0104] Titanium dioxide 10-20

[0105] filler:

[0106] CaCO 3 35-45

[0107] Kaolin 35-45

[0108] Auxiliary:

[0109] Cationic color fixing agent 2-3

[0110] Non-ionic color fixing agent 2-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com