Construction method with silo sliding formwork operating platform as top cover plate formwork supporting system

A technology of operating platform and formwork support, applied in formwork/formwork/work frame, processing of building materials, preparation of building components on site, etc. , to achieve the effect of improving the safety of construction operations, reducing labor intensity and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

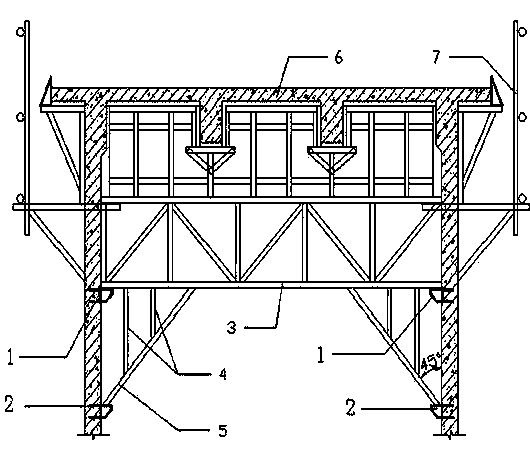

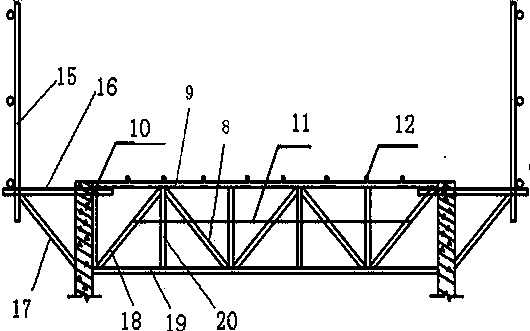

[0037] Embodiment: The project name of this embodiment: Shanxi Hongsheng Antai Co., Ltd. coal washing plant project. This project is composed of raw coal bunker, gangue bin, medium coal bunker and clean coal bunker. The silo has a diameter of 18m and a capacity of 7000t. (The diameter of the gangue bin is 8m, and the capacity is 400t). The total height of the cylinder wall is 43.56m, and the thickness of the roof of the bin is 180mm.

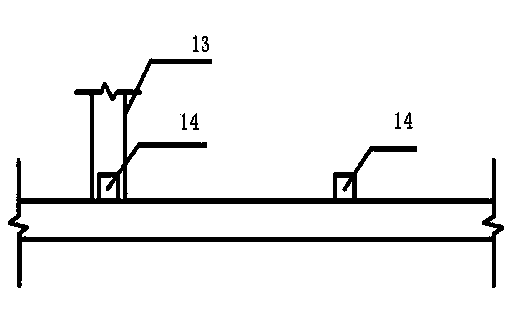

[0038] The construction steps of the silo synovial film operating platform as roof beam slab formwork include: design and calculation of the silo synovial film operating platform - production of the silo synovial film operating platform - pre-embedded steel corbel pre-embedded parts on the cylinder wall - pre-embedded mold removal rings on the cylinder wall —Hoisting of the silo slide film operating platform—welded steel corbels—installation of the silo slide film operating platform—installation of the formwork and support system (including the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com