Sealing part structure for high sealing performance oil pipe

A sealing part, high sealing technology, applied in the direction of drill pipe, casing, drilling equipment, etc., can solve the problem of thread reducing air tightness, and achieve the effect of improving the ability to resist bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

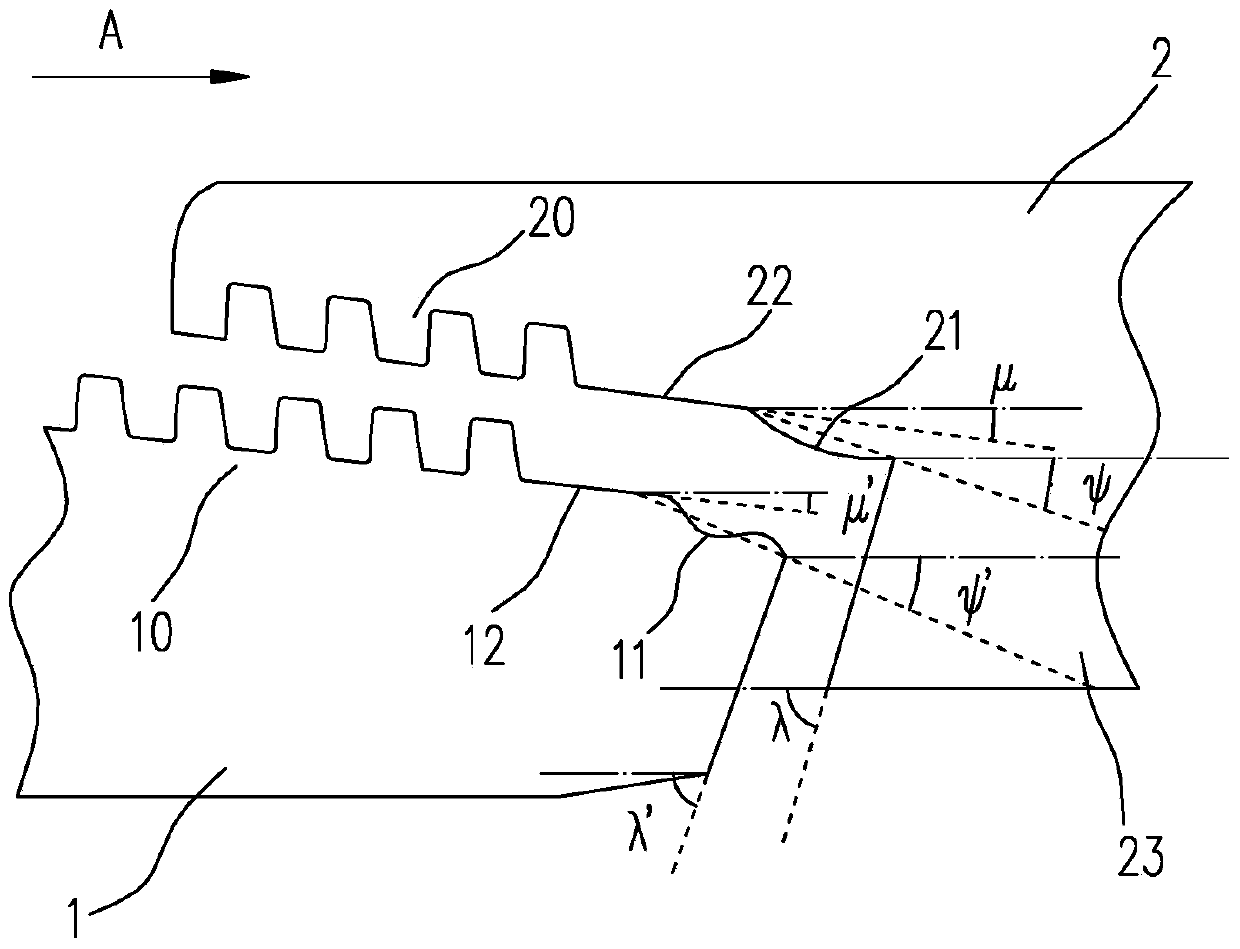

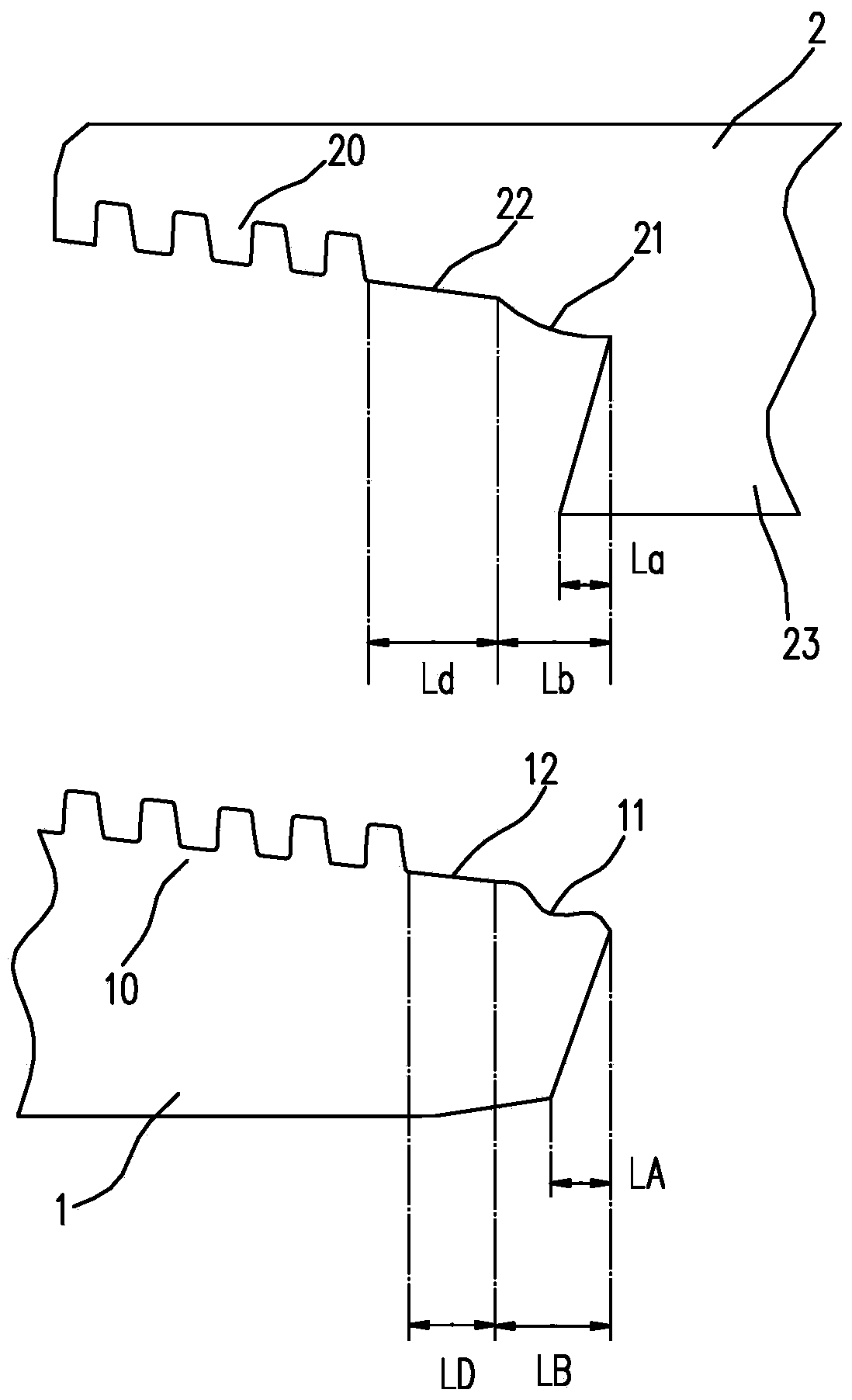

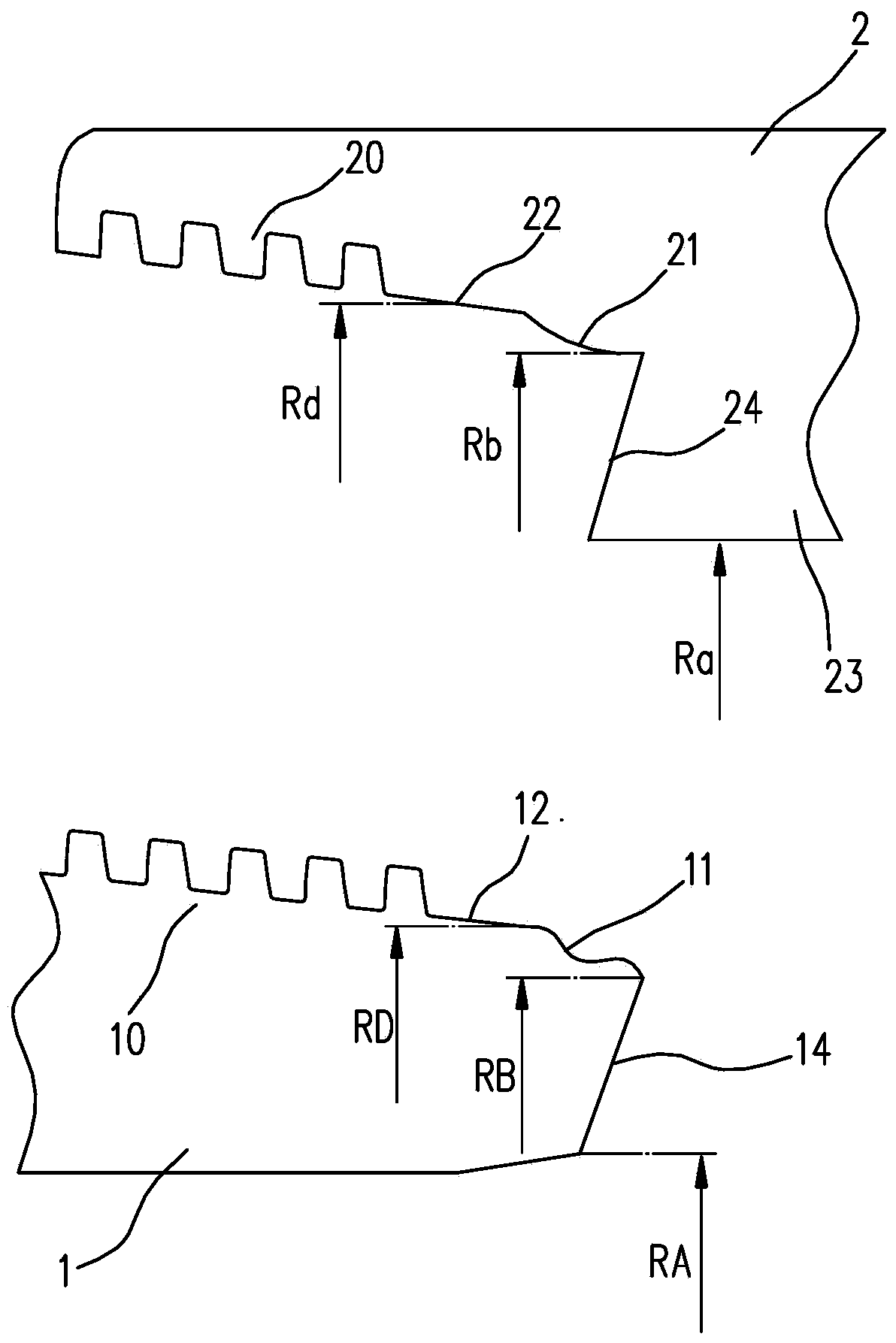

[0022] Such as figure 1 As shown, a sealing portion structure of a high-tightness oil pipe includes a pipe body 1 and a coupling 2, the outer circumference of the end of the pipe body 1 is provided with a pipe body thread 10 and a pipe body sealing portion 11, and the inner circumference of the coupling 2 is provided with There is a coupling thread 20 matching the pipe body thread 10 and a coupling sealing part 21 matching the pipe body sealing part 11, and the pipe body sealing part 11 is positioned at the front of the pipe body thread 10 screwing in direction (such as figure 1 The direction A shown is the screwing direction of the thread 10 of the pipe body. figure 1 A direction shown), the coupling sealing part 21 is located behind the screwing direction of the coupling part thread 20 (the screwing direction of the coupling part thread 20 is opposite to that of the pipe body part thread 10, that is, the opposite direction of A), and the pipe body 1 is also provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com