Low-section-height drift-pillar-free shrinkage-stoping, subsequent-filling and mining method

A backfill mining method with no bottom pillar technology, which is applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of open pit expansion, large loss and dilution of back mining ore, large exposed area, etc., and achieve stope stability Good performance, high ore recovery rate, high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

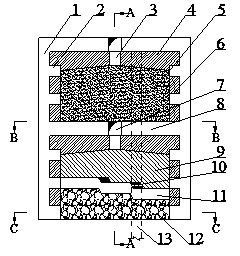

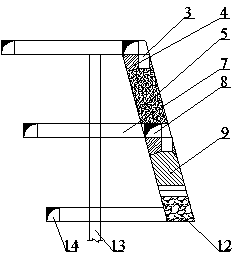

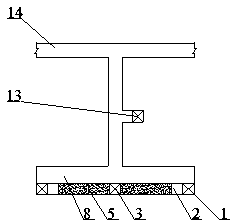

[0029] A low-section, high-pillar-free ore retention and subsequent filling mining method. The method described in this embodiment is:

[0030] 1) Sampling and cutting

[0031] This embodiment is the mining of a certain sporadic ore body. After the development project is completed, the sporadic ore body is divided into stages, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, stage transportation lanes 14 are arranged at each stage, and the vein-piercing roadway 7 is excavated from the stage transportation lanes 14 to reach the mine room to be mined; in the spacer column 6, a connecting road 2 is arranged vertically to connect The distance between road 2 is 3.0~3.5m, and the ventilated pedestrian patio 1 is connected with the mine house through the connecting road 2; the cutting is carried out in the mine house after the mining is completed, and the height of the bottom formed by cutting is 2~2.5m. The bottom width is the thickness of the ore body.

[0032]...

Embodiment 2

[0036] A low-section, high-pillar-free ore retention and subsequent filling mining method. The method described in this embodiment is:

[0037] 1) Sampling and cutting

[0038] This embodiment is the mining of a certain hanging side ore body. After the development project is completed, the hanging side ore body is divided into stages, such as Figure 5 , Figure 6 and Figure 7 As shown, stage transportation lanes 14 are arranged at each stage, and the vein-piercing roadway 7 is excavated from the stage transportation lanes 14 to reach the mine room to be mined; in the spacer column 6, a connecting road 2 is arranged vertically to connect The distance between road 2 is 3.5~4.0m, and the ventilated pedestrian patio 1 is connected with the mine house through the connecting road 2; the cutting is carried out in the mine house after the mining has been completed, the height of the bottom formed by cutting is 2~2.5m, and the The bottom width is the thickness of the ore body.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com