Online connection preparation method for C/SiC materials

A wire connection and composite material technology, applied in the direction of connection components, mechanical equipment, threaded fasteners, etc., can solve the problems of affecting the connection strength of materials, high porosity of the connection surface, and easy loosening, so as to prevent loosening and improve Connection strength, porosity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

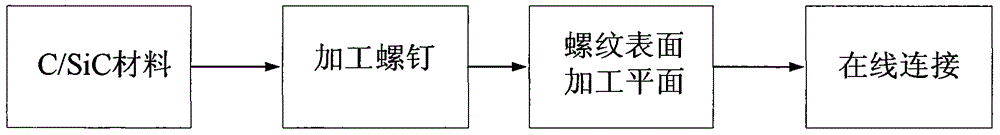

Method used

Image

Examples

Embodiment 1

[0023] On-line screw connection of two C / SiC composite material samples

[0024] 1. Process two C / SiC samples with a size of 15mm×15mm×10mm, and machine a M8 countersunk threaded hole in the center.

[0025] 2. Screw processing

[0026] A countersunk screw made of C / SiC material with a length of 20mm is machined out. The thread surface of the C / SiC screw is processed into a plane parallel to the XY plane of the material, and the processing depth is 0.1mm.

[0027] 3. Use screws to connect two C / SiC samples online.

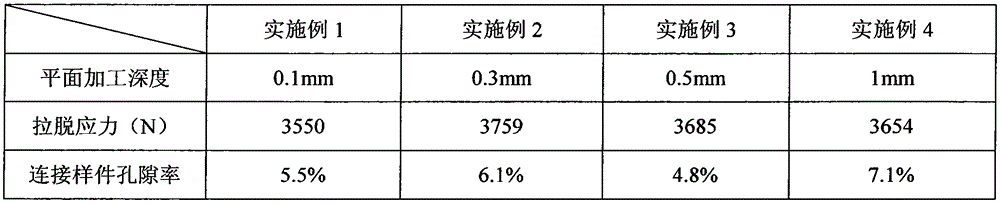

[0028] The prepared samples are analyzed, and the tensile strength is used to detect the pull-off stress assessment. The test results are shown in Table 1.

Embodiment 2~4

[0030] The preparation method is the same as in Example 1, the difference is that the processing depths of the thread surface processing planes of C / SiC screws are 0.3mm, 0.5mm and 1mm respectively, and the prepared samples are analyzed (the detection method is the same as in Example 1), and the detection results are shown in Table 1 shown.

[0031] Table 1

[0032]

[0033] It can be seen from Table 1 that when the plane processing depth is between 0.1-1mm, there is little difference in strength and porosity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com