PCB hole site and hole diameter detecting system and detecting method

A detection system and hole position technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of multi-working hours, labor energy, enterprise economic loss, impact on delivery time, etc., to save human resources and reasonable structural design , the effect of fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

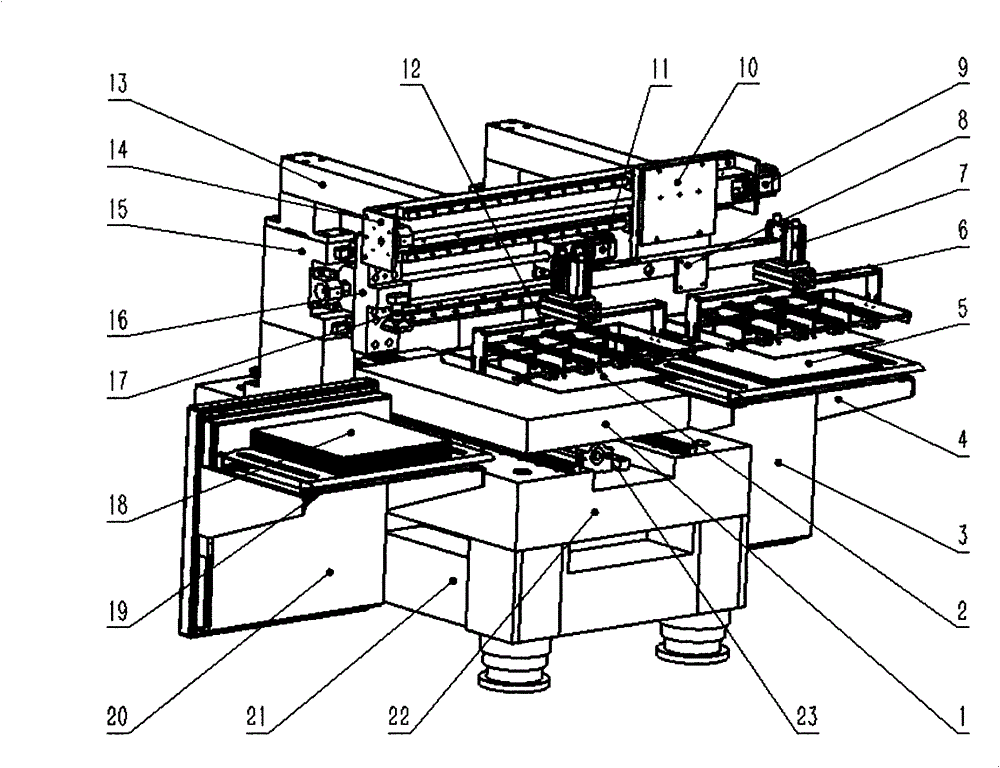

[0038] Such as figure 1 As shown, the driving part 3 of the feeding worktable consisting of a motor, a lead screw and a lead screw nut drives the feeding workbench 4 to rise by one plate thickness unit, and the upper and lower cylinders 7 of the manipulator move downward. When the right manipulator 6 grabs the undetected After the PCB board 5 and the left manipulator 12 grab the PCB board 2 that has just been detected, the upper and lower cylinders 7 of the manipulator rise, and then the left manipulator 12 and the right manipulator 6 are driven by the manipulator drive part 9 composed of a motor, a lead screw and a nut. Driven to move to the left as a whole. When the left manipulator 12 grabs the newly detected PCB board 2 and moves to the top of the unloading workbench 19 and the right manipulator 6 grabs the undetected PCB board 5 and moves to the top of the detection workbench 1, the upper and lower cylinders 7 of the manipulator move downward. , the left manipulator 12 p...

Embodiment 2

[0041] The difference between embodiment 2 and embodiment 1 is that there is an unloading workbench 19 at the bottom of the same side of the camera support beam 15, which automatically unloads the detected PCB, saves labor and improves detection efficiency.

[0042] The manipulator driving part 9 is a screw transmission mechanism composed of a motor, a leading screw and a leading screw nut

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com