Incident light lens for counting oil particles

A particle counting and incident light technology, which is applied in the field of optical detection, can solve the problems of light intensity, particle resolution reduction, and small projected area of the detection area, achieving high light transmittance, improving test resolution, and reducing design difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

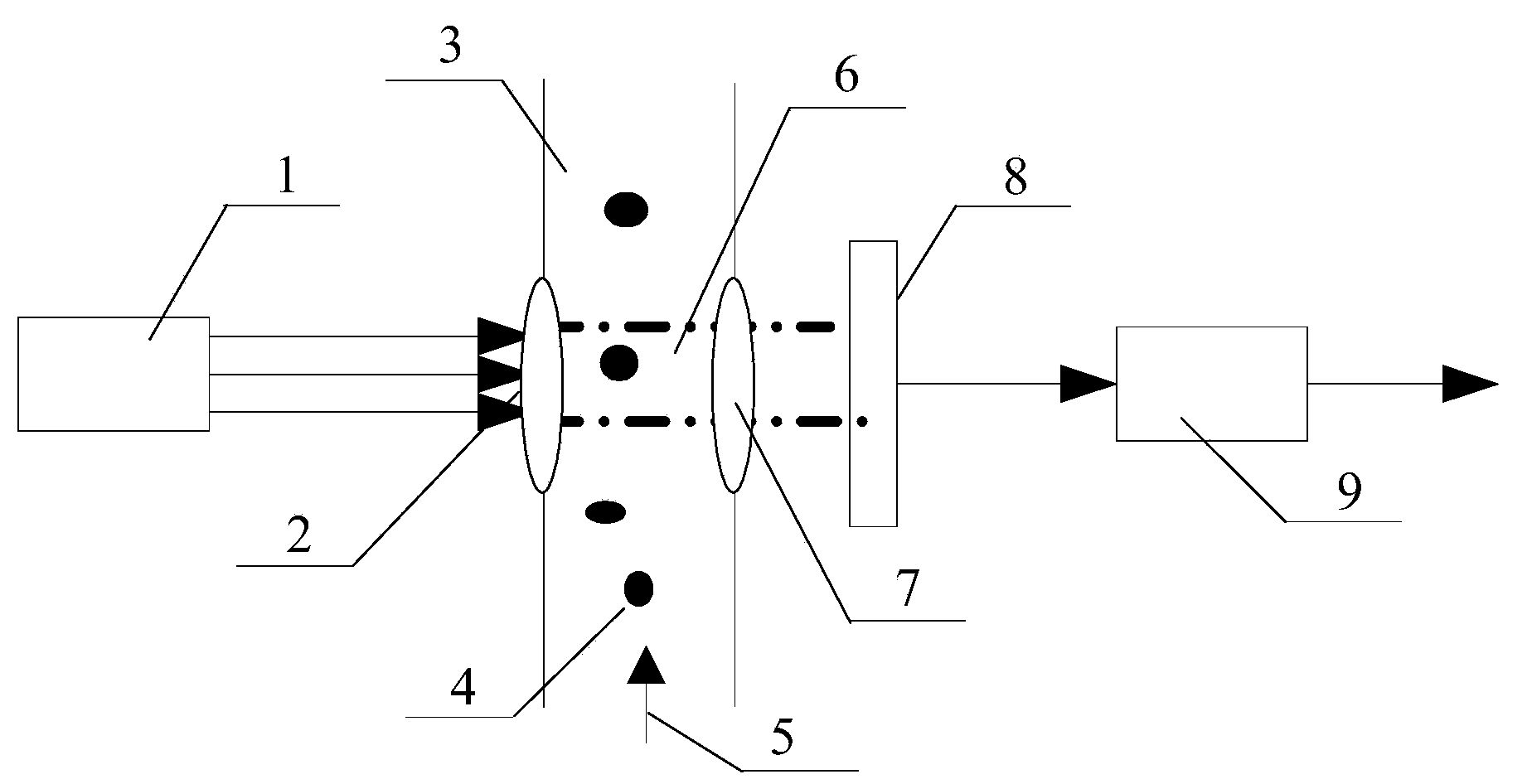

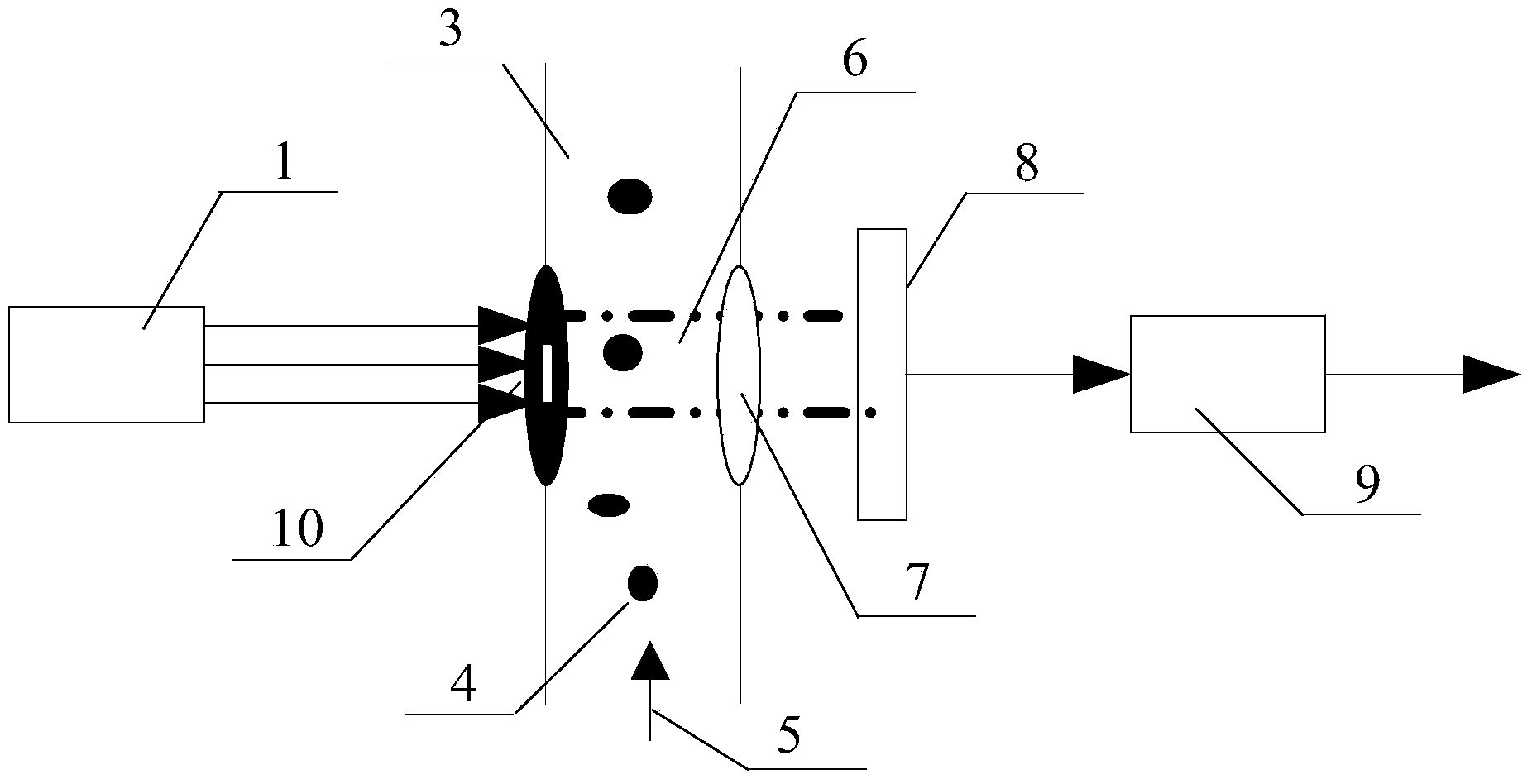

Method used

Image

Examples

Embodiment

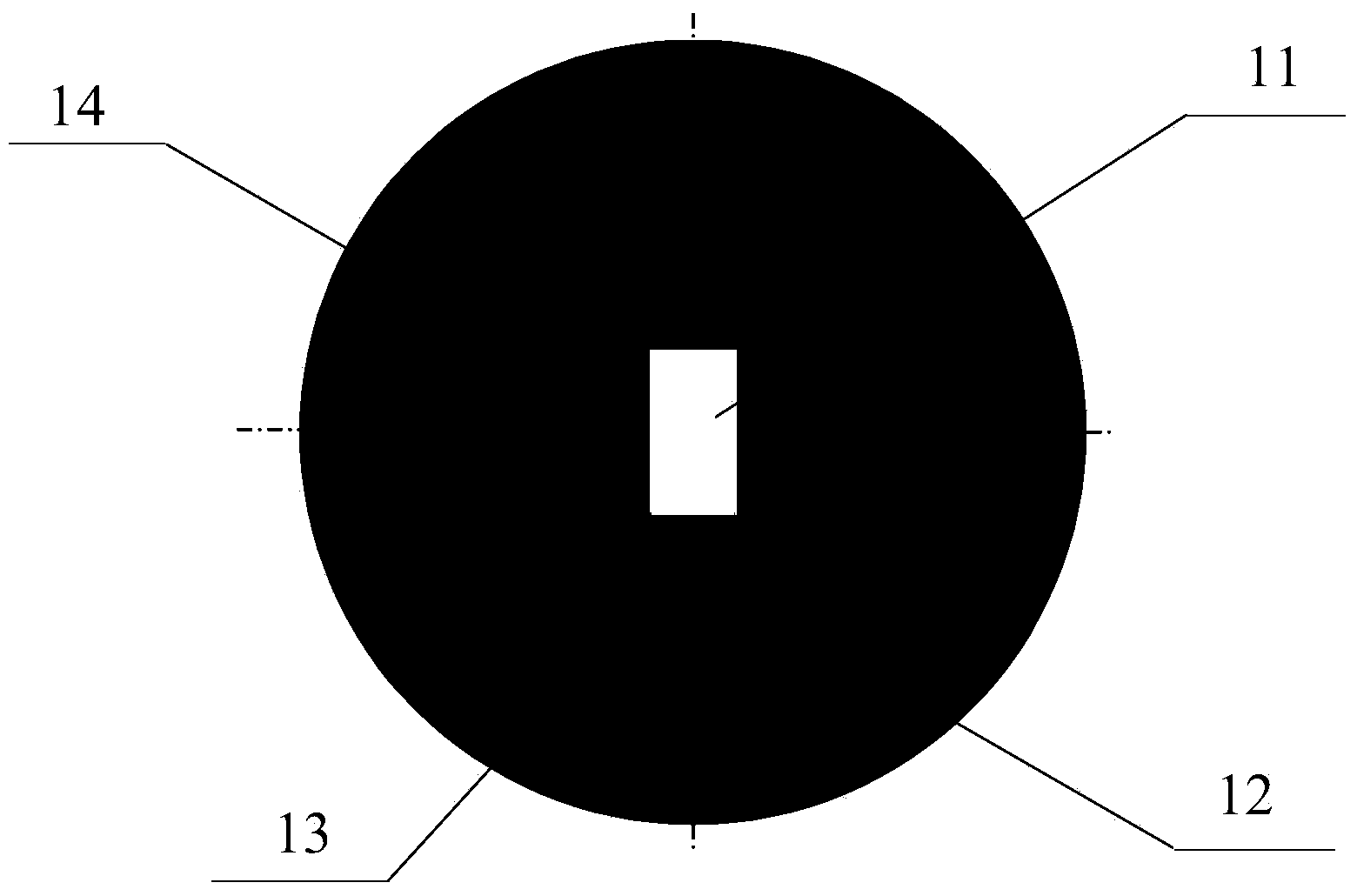

[0017] For example, to achieve particle measurement with a maximum size of 21um, the incident light lens 10 is made of artificial sapphire, which is processed into a cylinder with a diameter of 6mm and a thickness of 1mm, and then a layer of metal is coated on one plane of the incident light lens Chrome 12, thickness 0.1mm. A rectangular window 11 is engraved in the center of the side of the incident light lens 10 plated with metal chromium 12 by chemical etching. The length 14 of the rectangular window 11 is 0.8 mm, and the width 13 is 0.1 mm.

[0018] Install the incident light lens 10 and the outgoing light lens 7 on both sides of the valve block respectively. During the installation process, keep the incident light lens 10 and the light emitting surface of the light emitting diode 1, the outgoing light lens 7, and the receiving surface of the photodiode 8 in parallel with each other. The center is aligned; in the case of pure oil in the oil pool, power is supplied to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com