Optical exposure equipment, exposure method adopted by optical exposure equipment and display device production system

A technology of optical alignment and alignment, applied in optics, nonlinear optics, instruments, etc., can solve the problems of high light intensity, high manufacturing cost, and poor flexibility in adjusting illumination uniformity, so as to achieve uniform optical alignment, ensure quality, and avoid optical alignment The effect of poor uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

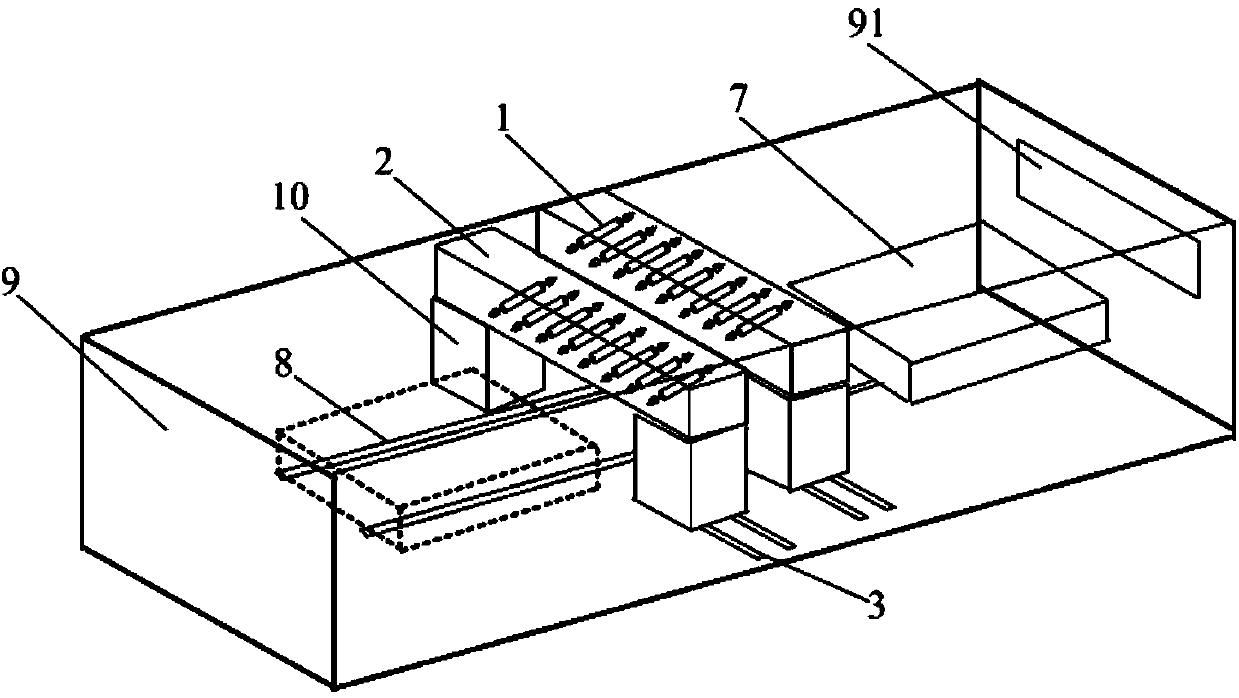

[0040] This embodiment provides an optical alignment device, which includes an optical alignment mechanism and an alignment area for a substrate to be aligned. The optical alignment mechanism includes an alignment unit and a stepping unit for driving the alignment unit to move. The alignment unit is used to align the substrate to be aligned. The unit includes a plurality of light sources arranged uniformly at intervals, and the stepping unit is used to drive the alignment unit to move, and the movement direction of the alignment unit is the same as the arrangement direction of the light sources.

[0041] Below to figure 2 As an example, the solution of the present invention is introduced in detail.

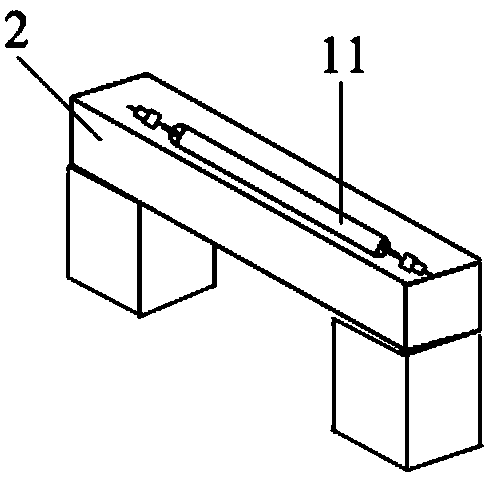

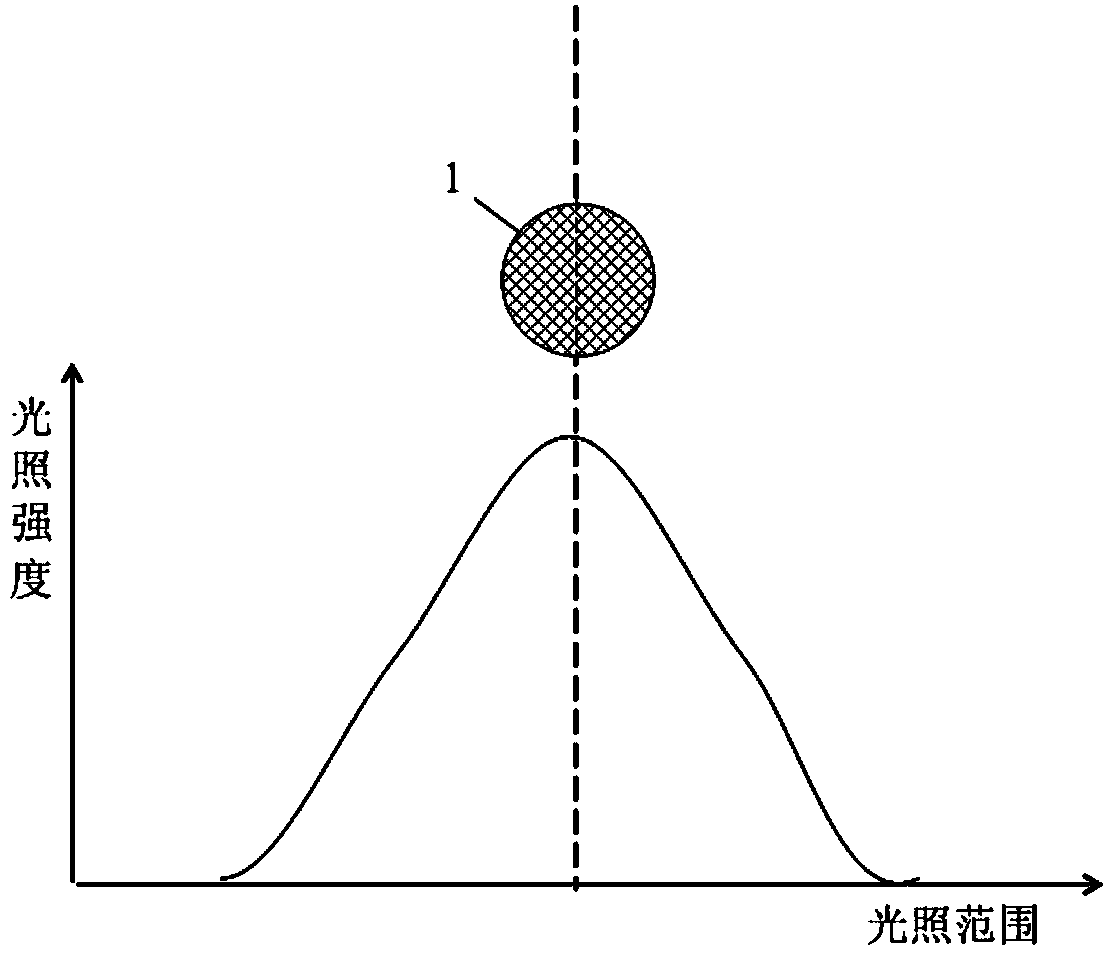

[0042] Such as figure 2 As shown, the light source can include a line light source 1, and the alignment unit also includes a box body 2, the box body 2 can be in the shape of a cuboid (of course, it can also be in other shapes), and a plurality of line light sources 1 are arran...

Embodiment 2

[0069] This embodiment provides an optical alignment device. The difference from Embodiment 1 is that N=1 in this embodiment, that is, the alignment unit includes only one box 2 . Other structures and settings of the optical alignment device are the same as those in Embodiment 1, and will not be repeated here.

[0070] This embodiment also provides an alignment method of the optical alignment device, which is different from the alignment method in Embodiment 1 in that it is based on the illumination intensity of the line light source 1 selected in Embodiment 1 and the set adjacent line light source 1 (that is, the number of line light sources 1 in a box 2 is also the same as that in Embodiment 1), and on the basis that the stepping unit drives the alignment unit to move a stepping distance L / 4 at a time, The alignment unit in this embodiment needs to step and move in the same direction three times. Correspondingly, the substrate to be aligned needs to go back and forth along t...

Embodiment 3

[0076] This embodiment provides an optical alignment device. The difference from Embodiment 1-2 is that in this embodiment, N=3, that is, the alignment unit includes three identical boxes, and the adjacent boxes are sequentially staggered in the length direction by L The / 3 spacing is arranged, so that the spacing between two adjacent line light sources in any two adjacent boxes of the three boxes is L / 3. The moving distance of the alignment unit along the first track driven by the stepping unit once is L / 6. Other structures and settings of the optical alignment device are the same as those in Embodiment 1, and will not be repeated here.

[0077] In this embodiment, since the spacing L between adjacent line light sources in a single box is the same as that in Embodiment 1, the spacing between two adjacent line light sources in two adjacent boxes is set to L / 3, And the single movement distance of the alignment unit is set to L / 6, so that the alignment unit can more uniformly i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com