A method for manufacturing a large-diameter high-precision composite material antenna surface

A composite material and manufacturing method technology, applied to antennas, electrical components, etc., can solve the problems of high energy consumption, low efficiency, high cost, etc., and achieve the effect of speeding up the progress of the project, reducing the manufacturing cost, and improving the quality of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] combine Figures 1 to 11 , the present invention will be further described below.

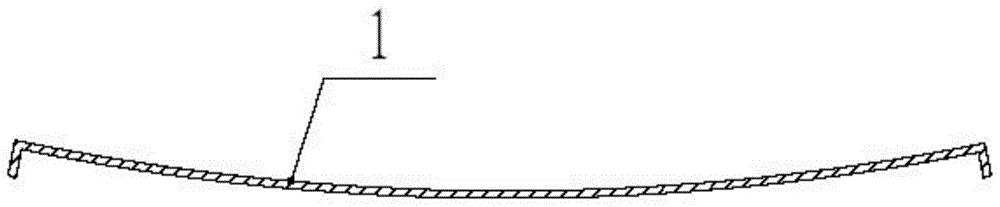

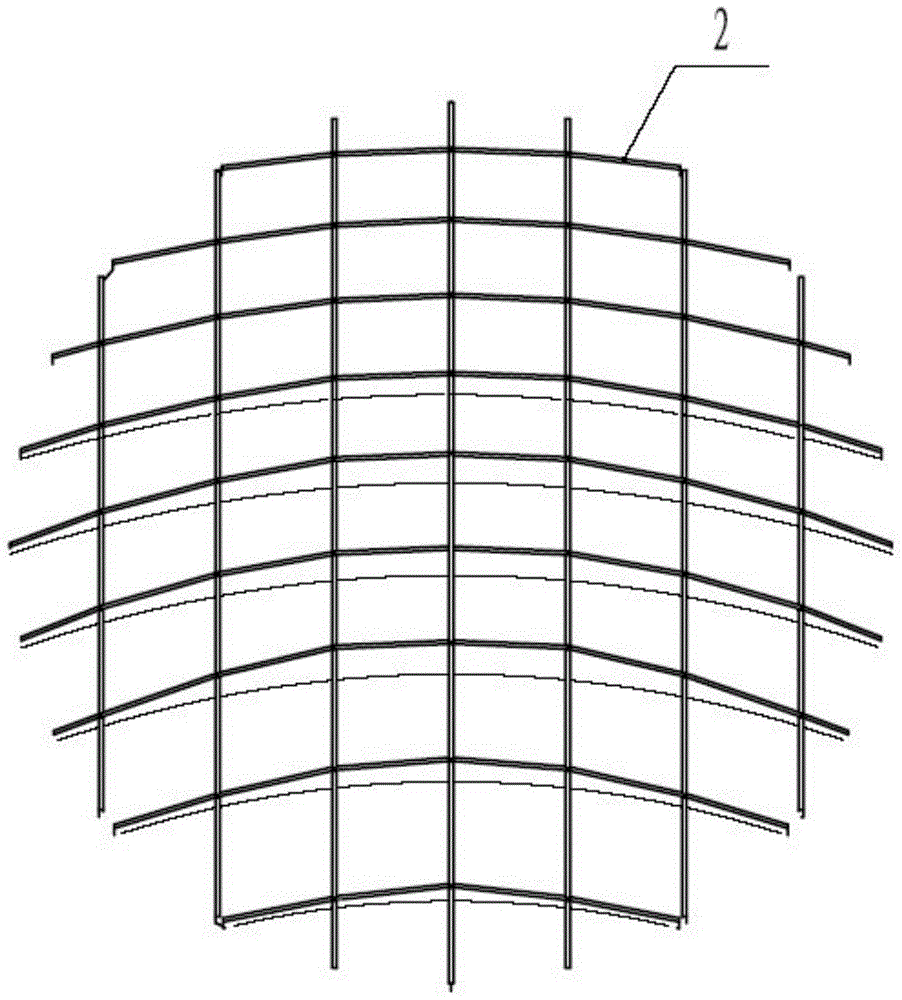

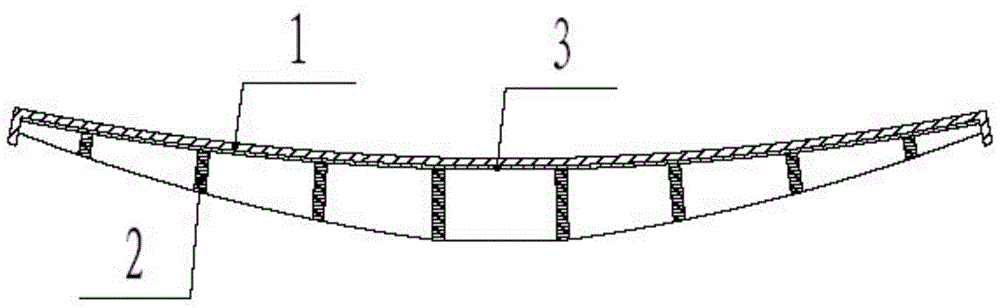

[0051] A method for manufacturing a large-diameter high-precision composite material antenna surface, the antenna surface includes a large-diameter main reflector 1 with a parabolic structure and a large-diameter main reflector 1 placed on the back and used to support the large-diameter main reflector 1 The back frame 2, the back frame 2 is a spatial grid structure formed in a vertical and horizontal orthogonal manner, the spatial grid structure of the back frame 2 matches the back of the large-diameter main reflecting surface 1 and is bonded by a structural adhesive 3, and formed The final large-aperture high-precision composite antenna surface structure is as follows: image 3 , 11 Shown; It is characterized in that: the molding method of large-diameter main reflective surface comprises the following steps:

[0052] ①Establish the curved surface mathematical model of the large-diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com