A flexible memory alloy support device for a small-caliber light mirror

A memory alloy, supporting device technology, applied in measuring devices, installations, force/torque/work measuring instruments, etc., can solve the problems of high precision of mirror surface type and assembly process requirements, achieve weight reduction, simplify overall structure, and avoid stress concentrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

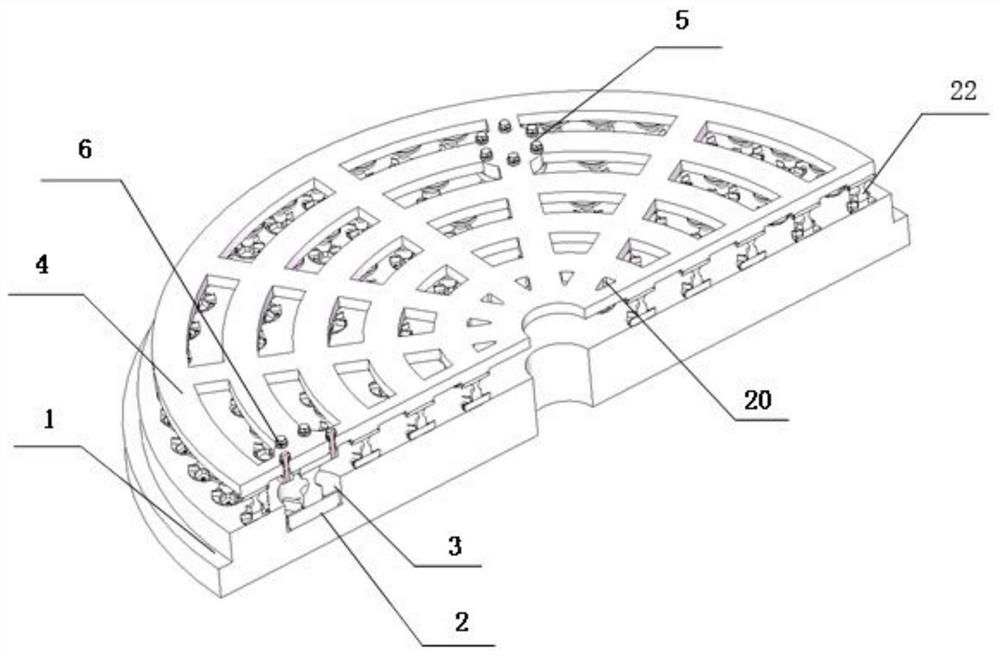

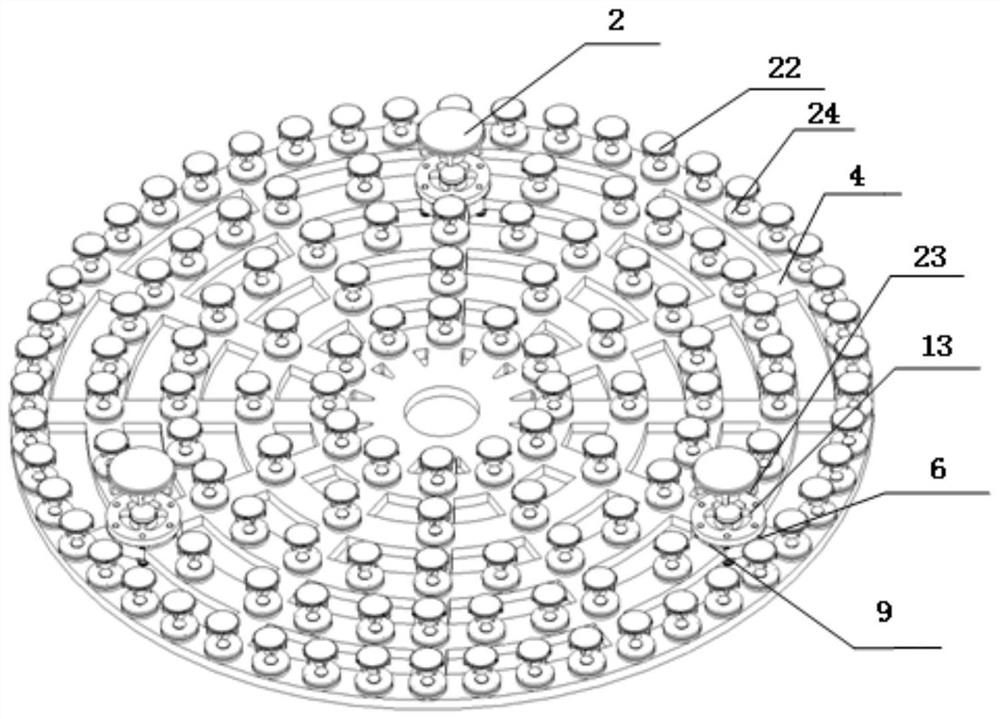

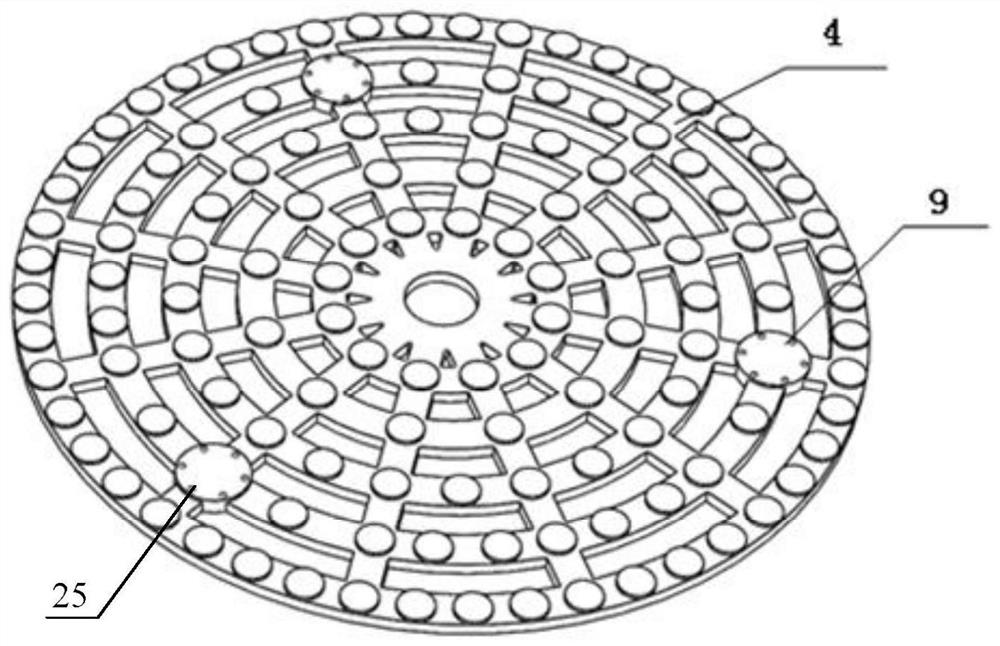

[0044] Such as figure 1 , 2 Shown in and 3, a flexible memory alloy support device for a small-caliber lightweight reflector includes a flexible support unit 2, a pressure sensor 8, a memory alloy fine-tuning unit 22, a support base 4, a fixing unit 5 and a computer. The end surface of the support base 4 is provided with concentrically distributed n weight-reducing groove groups, n≥5; the weight-reducing groove group includes k weight-reducing grooves uniformly distributed along the circumferential direction, k≥6; the innermost weight-reducing groove The weight-reducing grooves of the first group are fan-shaped, and the weight-reducing grooves of the other groups of weight-reducing grooves are fan-shaped; the joints of the two radii of the fan-shaped weight-reducing grooves and the joints of each radius and the arc are provided with a transition fillet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com