Joint manufacturing method

A manufacturing method and joint body technology, applied in the joint body field, can solve the problems of low current, short high strength joint body, composite body deflection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0140] (composite material)

[0141] Carbon fibers (Tenax STS40 manufactured by Toho Tenax Co., Ltd., average fiber diameter: 7 μm) with an average fiber length of 20 mm are randomly arranged and cut so that the average unit weight is 540 g / m 2 1. The weight ratio of carbon fiber is 52%, and the matrix is made of UNITIKA nylon 6 manufactured by UNITIKA Co., Ltd. to make a carbon fiber composite material.

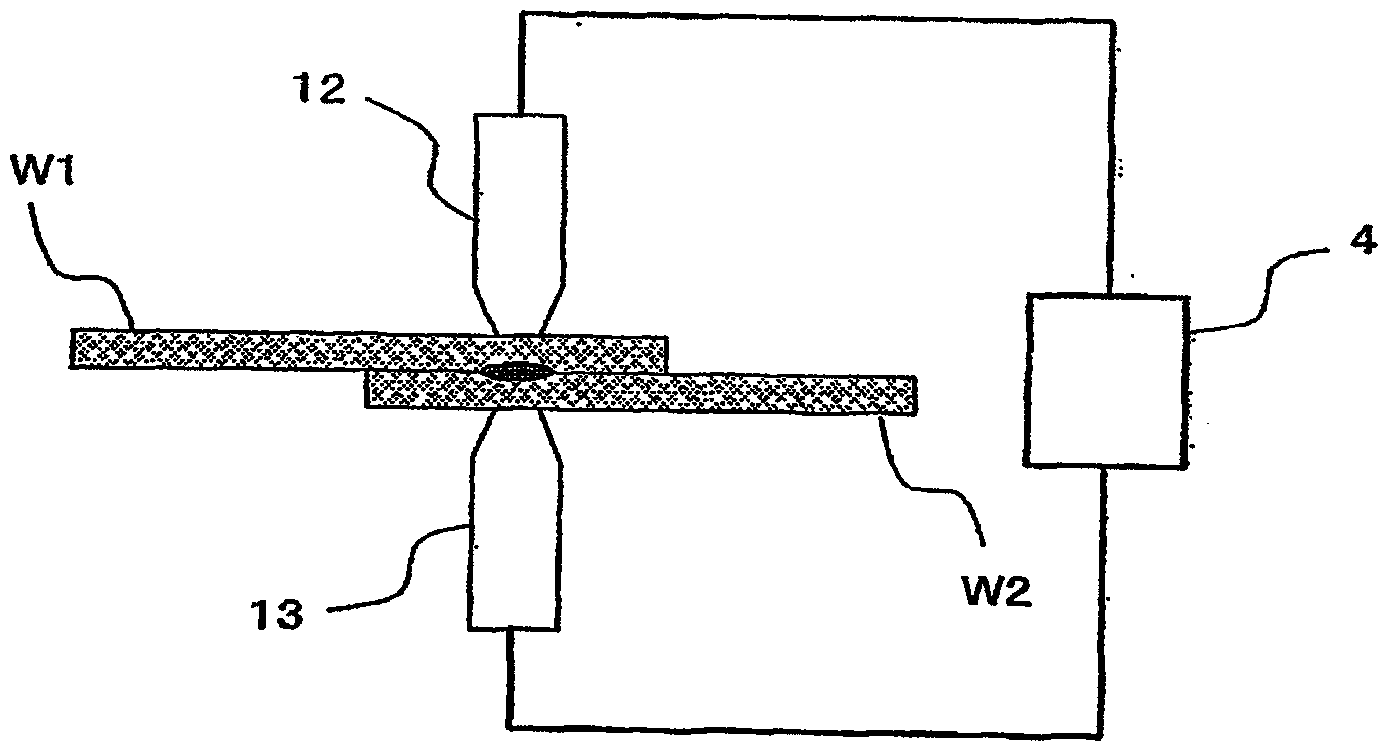

[0142] (fixed, powered up)

[0143] Two plates with a size of 100mm×25mm×2mm were prepared from the composite material and superimposed, and the superimposed part was clamped by electrodes. At this time, a copper electrode with a tip of Φ12 was used, and the applied force was 6.6kN (58.4MPa). In the pressurized state, a current of 60A was applied for 1 second from a DC power supply. The number of joints is 1.

[0144] (Evaluation)

[0145] The obtained bonded body was subjected to a tensile shear test at a speed of 1 mm / min using a 300 kN capacity floor-standing unive...

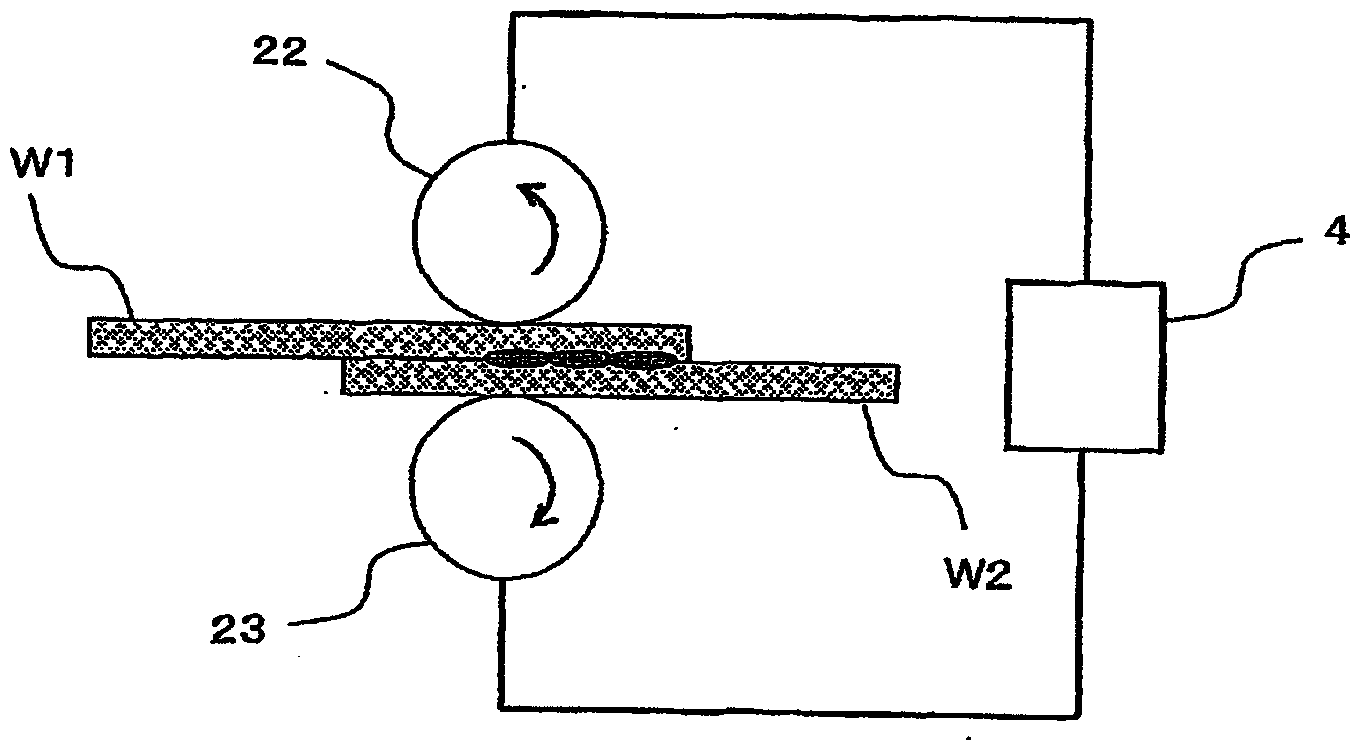

Embodiment 2

[0147] Two sheets of composite material same as in Example 1 were prepared and laminated, and clamped by a copper electrode with a front end of Φ5. The pressurization pressure is 3.4kN (173MPa), and the current of 60A is passed through the DC power supply for 2 seconds. The number of joints is 1.

[0148] (Evaluation)

[0149] The resulting bonded body was subjected to a tensile shear test at a speed of 1 mm / min using a 300 kN capacity floor-standing universal testing machine 5587 manufactured by Instron Corporation. The result was a breaking strength of 2.77 kN. It was confirmed that the obtained bonded body had no deformation such as warping.

Embodiment 3

[0151] (composite material)

[0152] Carbon fibers (Tenax STS40 manufactured by Toho Tenax Co., Ltd., average fiber diameter: 7 μm) with an average fiber length of 20 mm are randomly arranged and cut so that the average unit weight is 540 g / m 2 1. The weight ratio of carbon fiber is 52%, and the matrix is made of UNITIKA nylon 6 manufactured by UNITIKA Co., Ltd. to make a carbon fiber composite material.

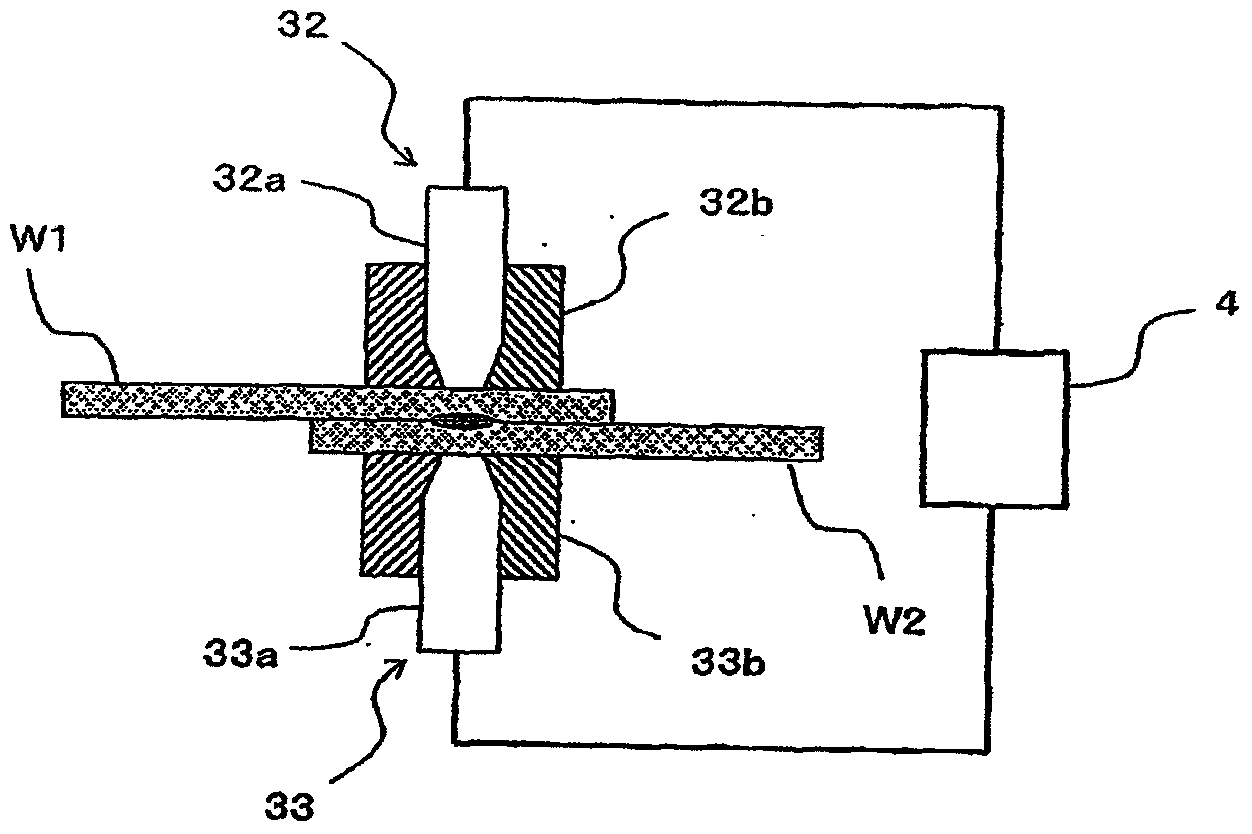

[0153] (fixed, powered up)

[0154] The composite material is used to prepare two plates with a size of 100mm×25mm×1.5mm and superimposed, and the superimposed part is clamped by electrodes. In this case, a Φ7 copper electrode is used on the inside, and a Φ16 fluororesin electrode with a pressurization assistant is used on the outside. The pressing force between the electrodes is 5.6kN (27.9MPa). Powered by a DC power supply in a pressurized state. In the first 0.5 seconds, the current value rises from 5A to 50A, and then remains energized at 50A for 1.5 seconds. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com