Electric Servo Steering System

A steering system and electric servo technology, applied in the direction of electric steering mechanism, steering mechanism, power steering mechanism, etc., can solve the problems of reducing the moving force of the power steering system and increasing the motion noise of the power steering system, so as to eliminate the running noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

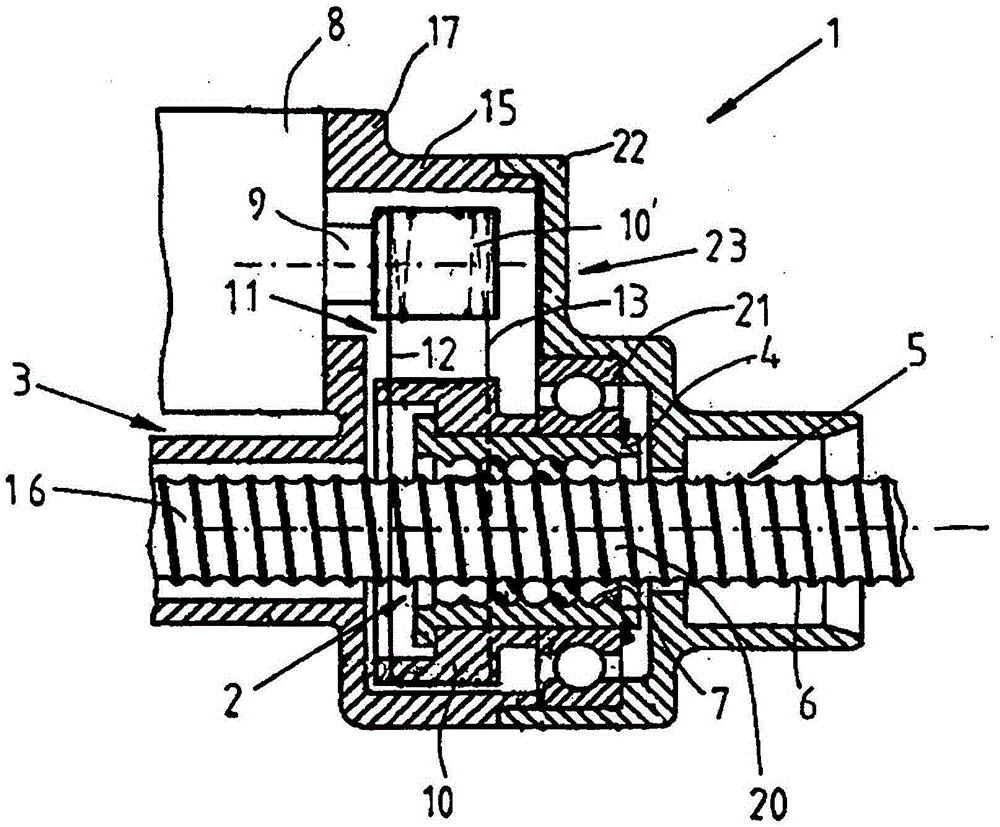

[0019] figure 1 A servo steering system 1 for a passenger car in the form of an electric rack power steering system is shown in a longitudinal section. The axially displaceable component 5 in the form of a toothed rack 16 is supported in a support 3 in the form of a cylindrical steering gear housing 15 . Parallel to the toothed rack 16 , a servomotor 8 is attached to a radial flange 17 of the steering gear housing 15 . The toothed rack 16 meshes on a meshing section with a pinion not shown on the steering shaft and has an external thread 6 on a main shaft section 20 which is in contact with the ball recirculation thread or internal thread of a nut 4 The threads 7 are engaged. The nut 4 and the spindle section 20 form a spindle 2 . The nut 4 is non-rotatably connected to a disk 10 and is supported via a radial bearing 21 on a carrier part designed as a housing cover 22 .

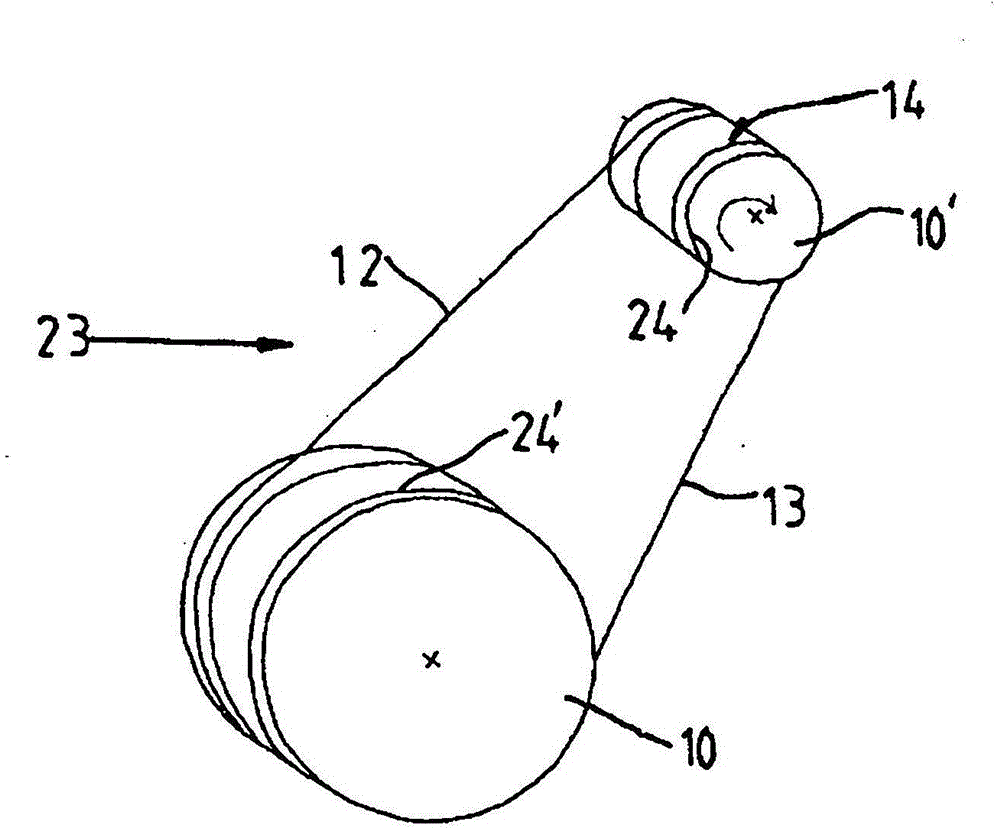

[0020] Attached to a shaft 9 of the servomotor 8 is a further disk 10 ′, which has a smaller diameter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com