Swing arm cam type two-stroke direct shaft internal combustion engine

A cam type, internal combustion engine technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of great influence on output efficiency and lack of smoothness of machine operation, and achieve simple manufacturing process, lighter body, and stable operation. sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

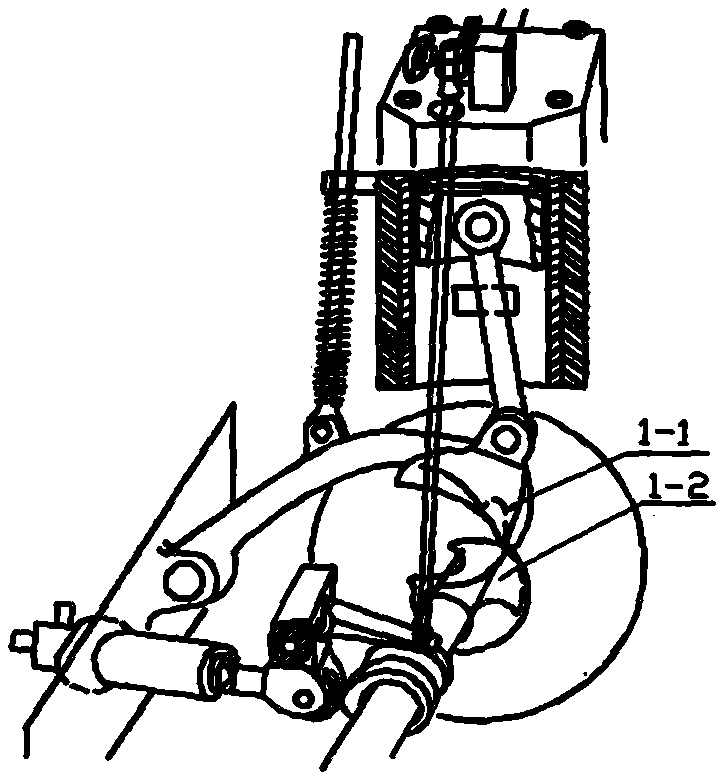

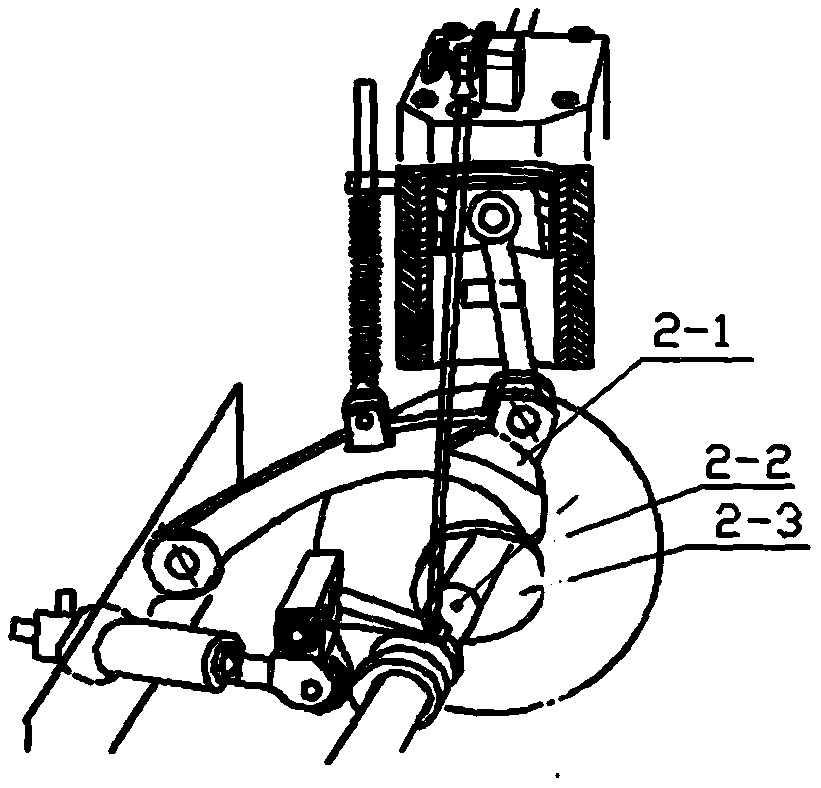

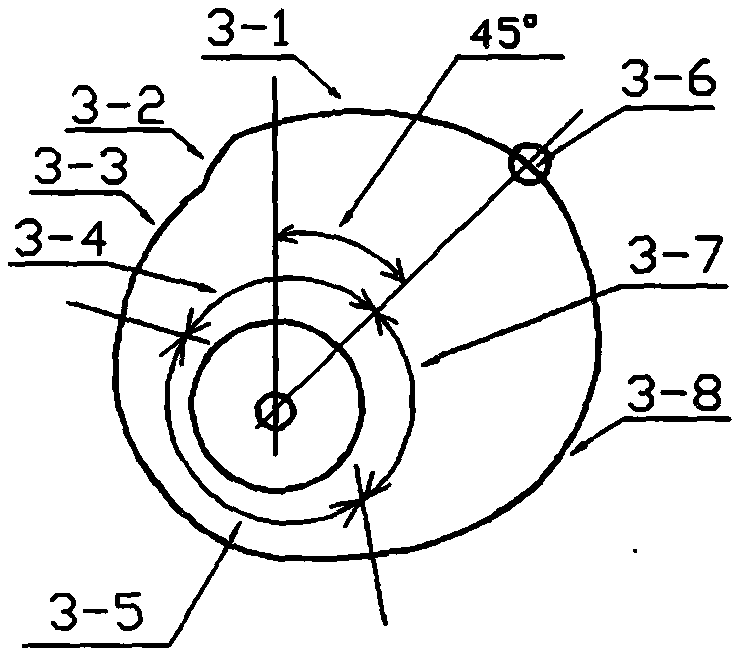

[0033] This embodiment is a single-cylinder one-unit internal combustion engine, and the specific structure is shown in the attached figure 2 , it consists of a single-track swing arm and an elliptical cam to form a matching unit, see the lower arc point at the front end of the single-track swing arm figure 2 2-2 in the middle, there is an arc slide at the back, see figure 2 In 2-1, there is a piston pin hole on the upper front end of the swing arm, see Figure 4 4-3 in the middle, there is a compression spring in the middle, and a hole connected to the chassis at the rear end of the swing arm, see Figure 4 In 4-1, there is an arc-shaped slideway at the lower part of the front end of the swing arm, see Figure 4 4-2 in, with an elliptical cam on a straight axis, see figure 2 In 2-3, the rotation fit makes the piston in the cylinder reciprocate up and down. The length from the center of the elliptical cam to the apex of the arc is further lengthened compared to the length f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com