Hydraulic circuit, method for operating same

A technology of hydraulic circuit and hydraulic medium, which is applied to non-mechanical drive clutches, elements with teeth, fluid drive clutches, etc., can solve the problems of poor clutch adjustment quality and achieve the effect of avoiding back pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

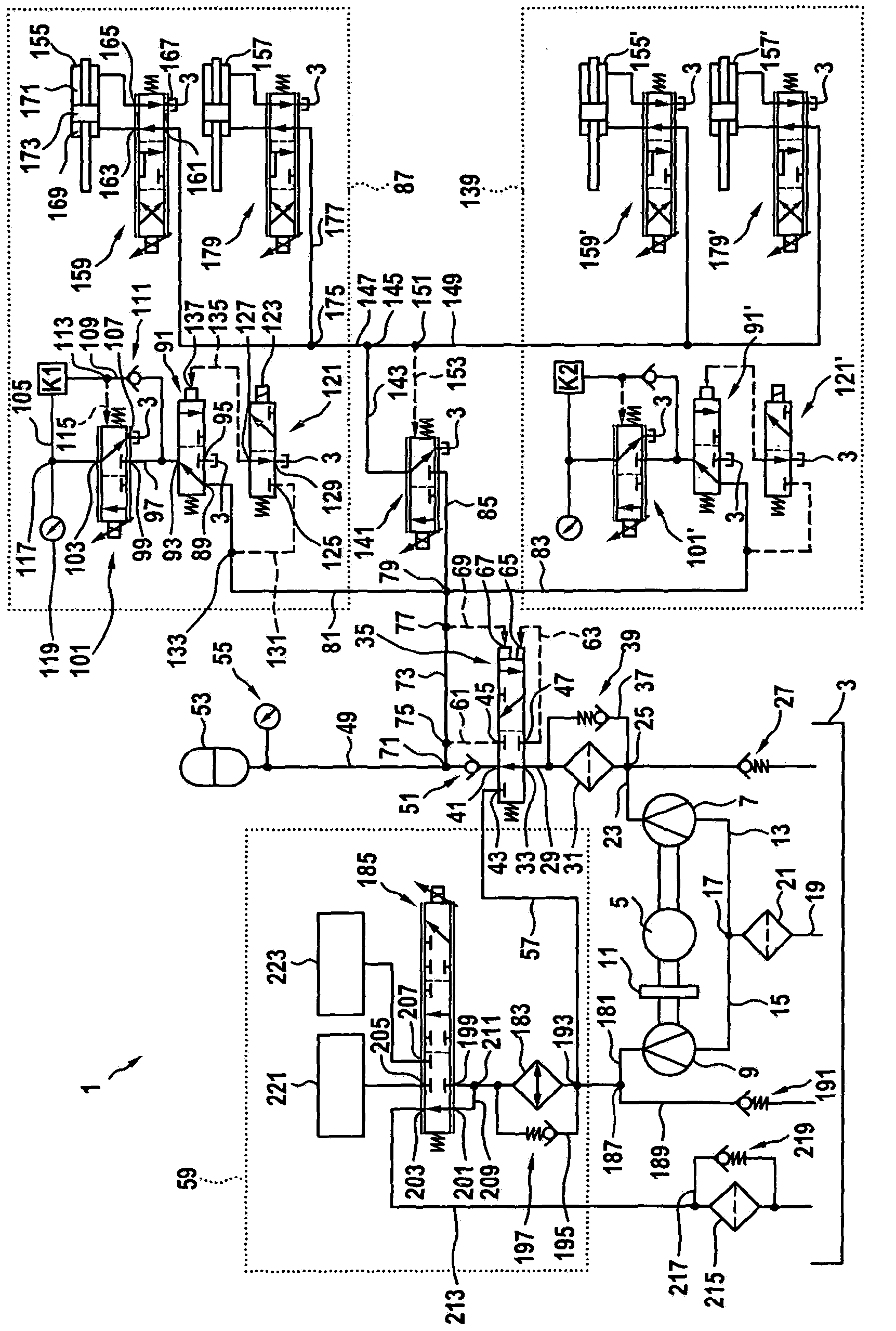

[0019] figure 1 A hydraulic circuit 1 is shown, which is used for cooling and actuating the dual-clutch transmission—in particular, coupling and engaging and disengaging gears. The hydraulic circuit 1 comprises a tank 3 which serves in particular as a storage container or reservoir for hydraulic medium for actuation and cooling, in which tank the hydraulic medium is stored preferably pressureless. An electric motor 5 is provided, which drives a first pump 7 and a second pump 9 . The electric motor 5 is preferably controllable, particularly preferably adjustable, with respect to its rotational speed and direction of rotation. The first pump 7 is fixedly connected to the electric motor 5 , ie no separating element is provided. This means that the pump 7 is always driven when the electric motor 5 is in operation and preferably delivers the hydraulic medium in a balanced manner in both directions of rotation. The pump 9 is preferably connected to the electric motor 5 via a sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com