Optical element

A technology of optical components and optics, applied in the direction of optical components, optics, optomechanical equipment, etc., can solve problems such as deformation of optical components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

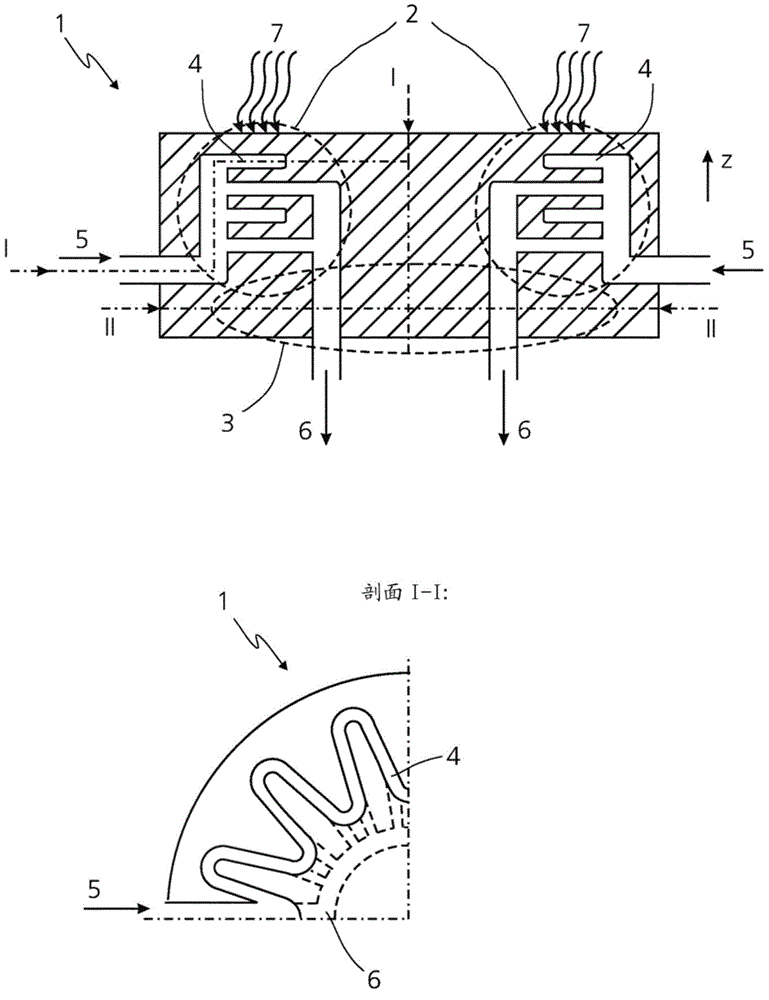

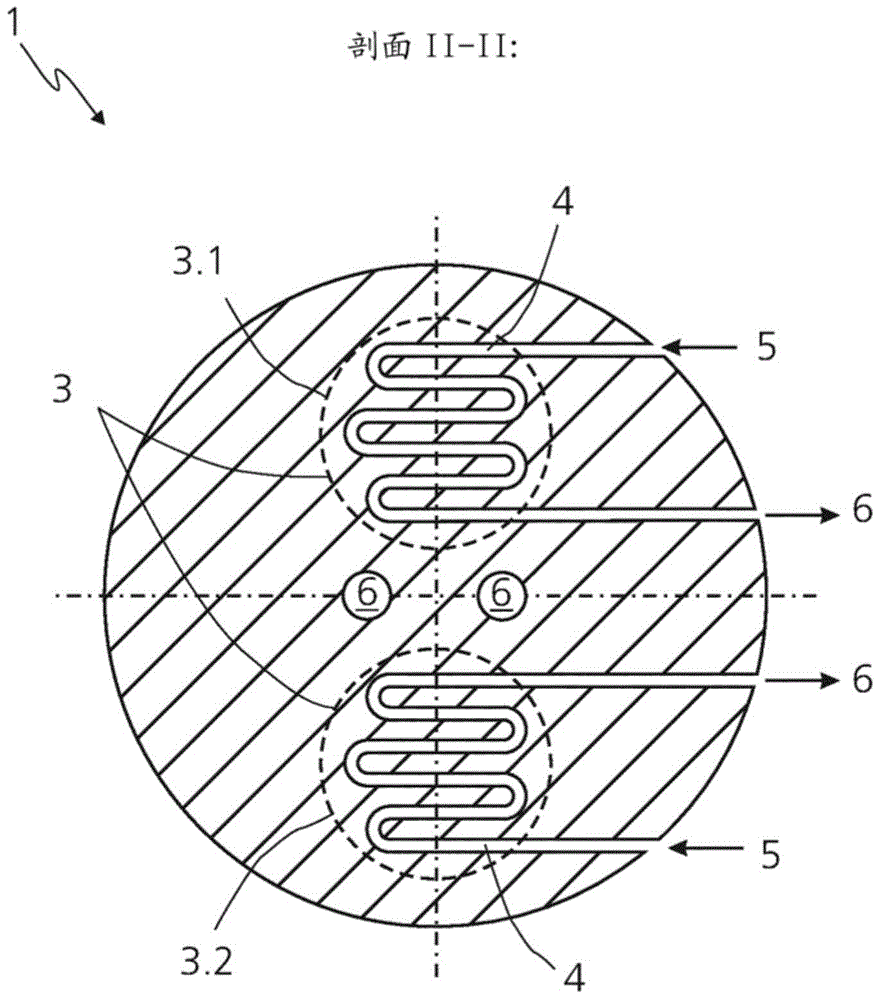

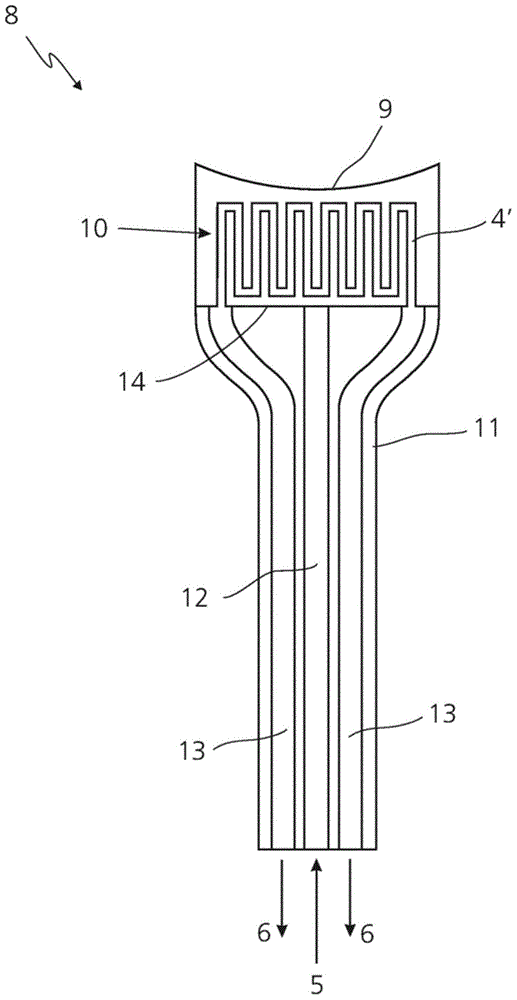

[0035] To spatially resolve these thermal distributions of the cooling optics, cooling bodies 1, 23 ( figure 1 , 2 and 5). The cooling body 1 shown can, for example, be fitted to a facet mirror or a deflecting mirror, or be implemented as a mirror carrier for an EUV deflecting mirror ( Figure 4 and 6 ). Figure 3a The possibility of incorporating microcoolers 10 into individual mirror facets 8 is shown.

[0036] figure 1 and figure 2 Shown is a cooling body 1 with cooling channels 4 leading into two cooling zones 2 and 3 , wherein the first cooling zone 2 is designed for annular heat loads and the second cooling zone 3 is designed for bipolar heat loads. figure 1 The optically active surface of the optical element is not shown, which is located in the region indicated by arrow 7 in the example shown. The cooling zone 3 is located in a deeper plane than the cooling zone 2 in the z-direction shown. In the heat sink 1 it is additionally possible to implement cooling cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com