Kitchen waste sorting device

A sorting device and a technology of kitchen waste, applied in the direction of solid waste removal, etc., can solve the problems of incomplete removal of impurities, difficult separation and complete damage to the crusher, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

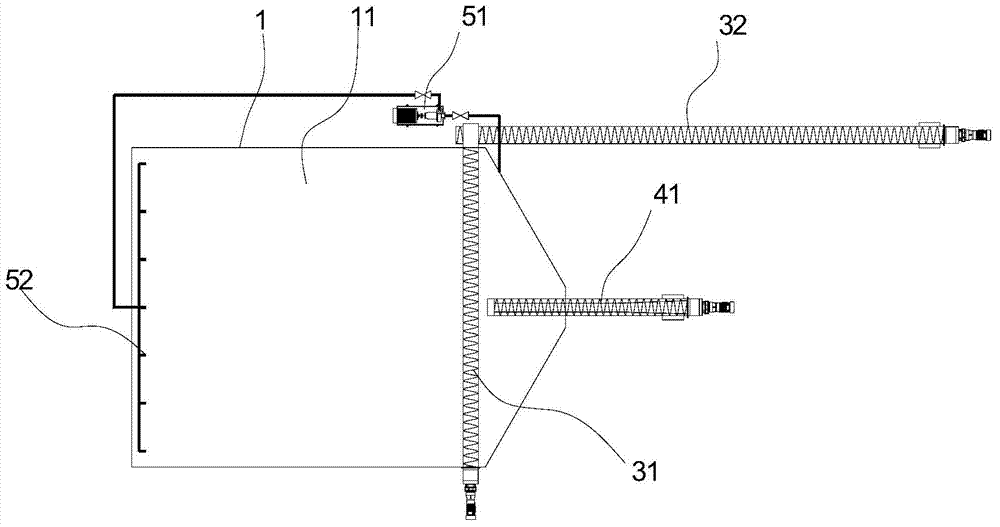

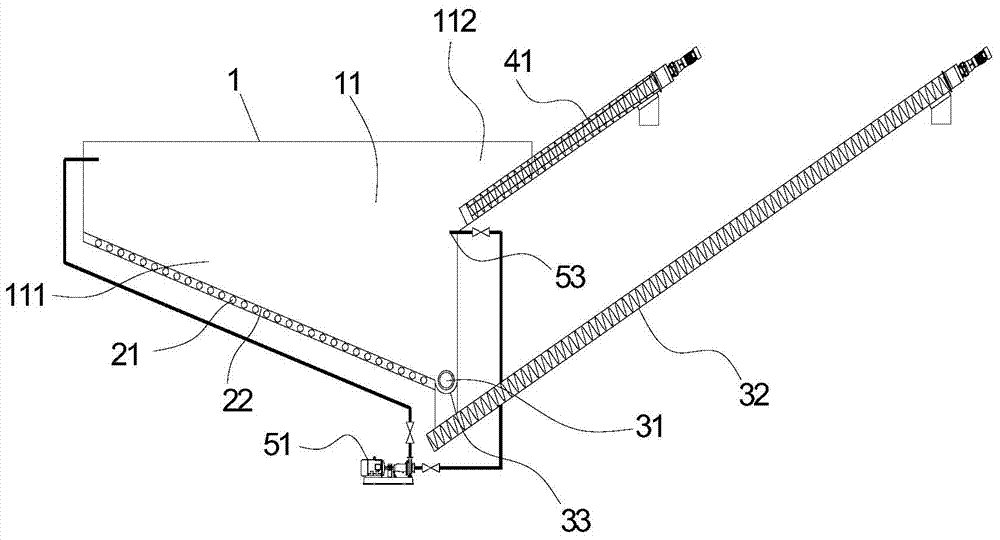

[0025] Please refer to figure 1 and 2 , The food waste sorting device provided in this embodiment includes a bucket body 1, an aeration pipe mechanism, a first impurity conveyor, a second impurity conveyor, and a water circulation system.

[0026] The bucket body 1 can be a hopper or a feed pool. The bucket body 1 shown in this embodiment is in the shape of a strip, and the bucket body 1 has an accommodating chamber 11 which is divided into a flotation sedimentation area 111 and a slag collection area 112 . The accommodating cavity 11 has an inclined bottom wall. The space corresponding to the inclined bottom wall in the accommodating chamber 11 is a flotation sedimentation zone 111 . A perforated plate 22 with a smooth surface and full of small holes is set on the upper floor of the inclined bottom, which is detachable. Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com