CNC lathe dual-channel water-cooled electric spindle

A CNC lathe, dual-channel technology, used in large fixed members, metal processing mechanical parts, maintenance and safety accessories, etc., can solve the problem that the heat dissipation effect cannot meet the needs of high-speed and high-torque processing, and save the space and structure of the fan installation. Simple and compact, the effect of improving heat dissipation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

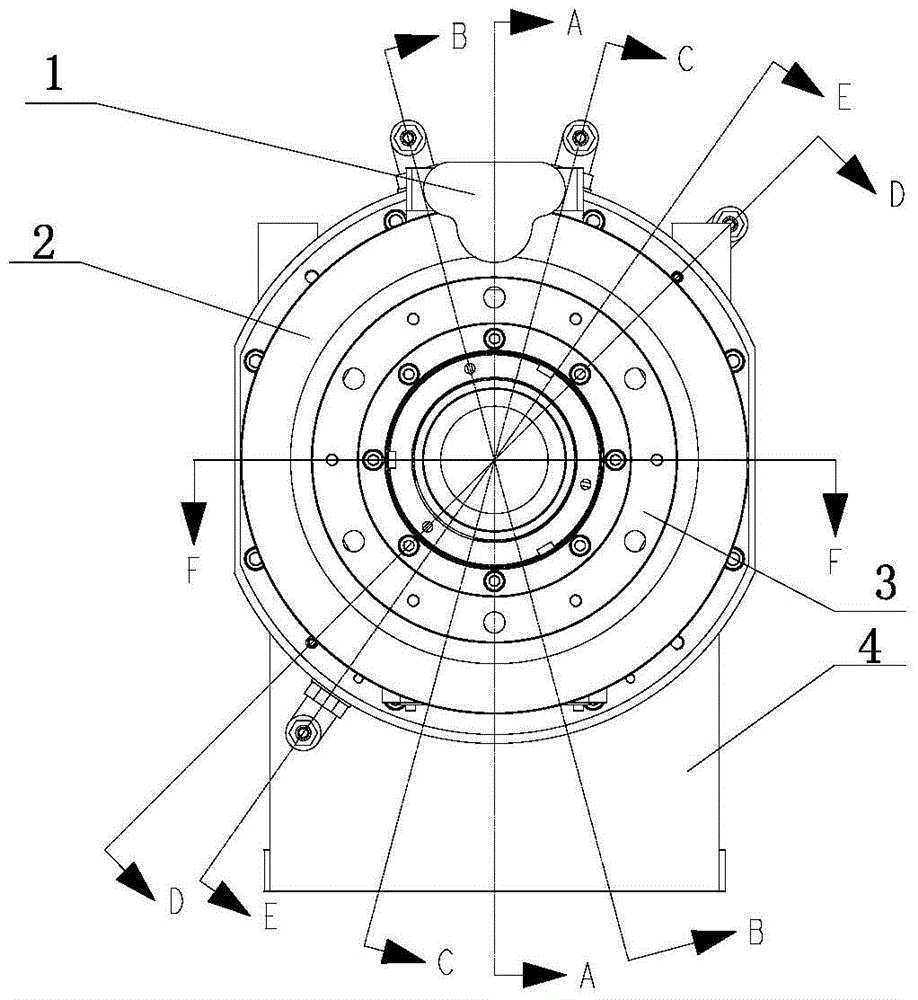

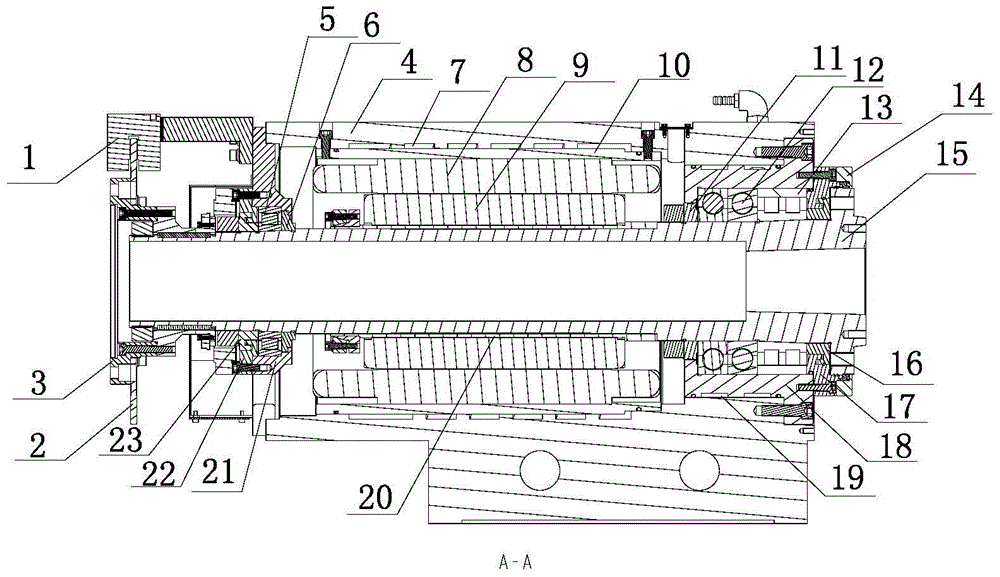

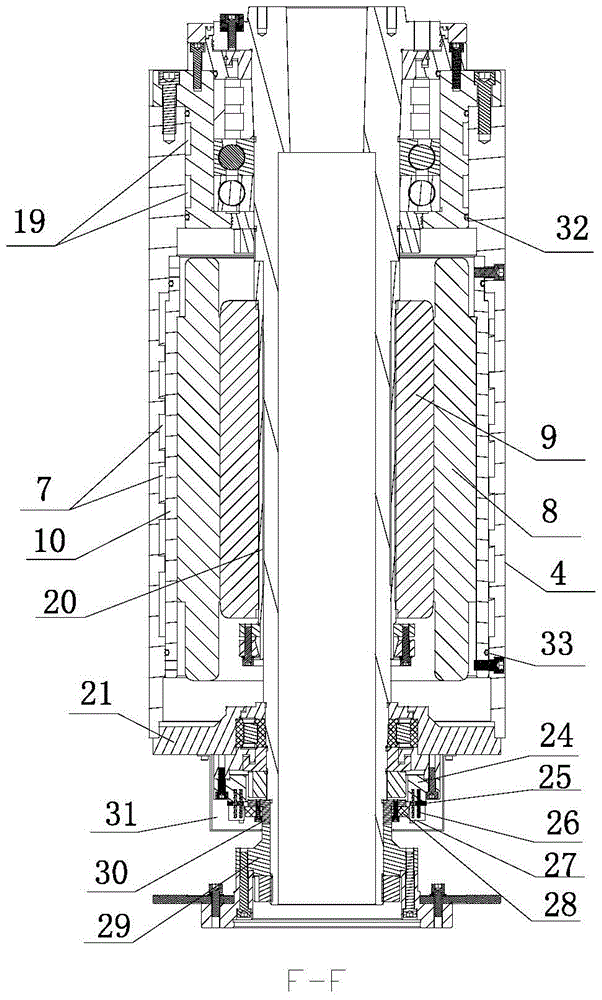

[0020] Such as Figure 1~Figure 7As shown, the present invention includes a main shaft housing 4, a front bearing support 18, a rear bearing support 21, a hollow main shaft 15, a main shaft drive mechanism, an angle encoder device, a braking device and a cooling system, and the main shaft housing 4 is provided with a main shaft The hole and the air pipe joint 34, the front bearing support 18 and the rear bearing support 21 are respectively installed at the front and rear ends of the main shaft hole, and the front bearing support 18 and the rear bearing support 21 are all provided with axial through holes, The axial through hole and the main shaft hole are concentric, the main shaft 15 is mounted in the main shaft hole, and the front end of the main shaft 15 is supported and installed on the axial through hole of the front bearing support 18 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com