Welding machine for box beam

A technology for welding machines and box girders, applied in welding equipment, metal processing, metal processing equipment, etc., can solve the problems of structural influence and low degree of automation, and achieve the effects of low cost, improved welding quality, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

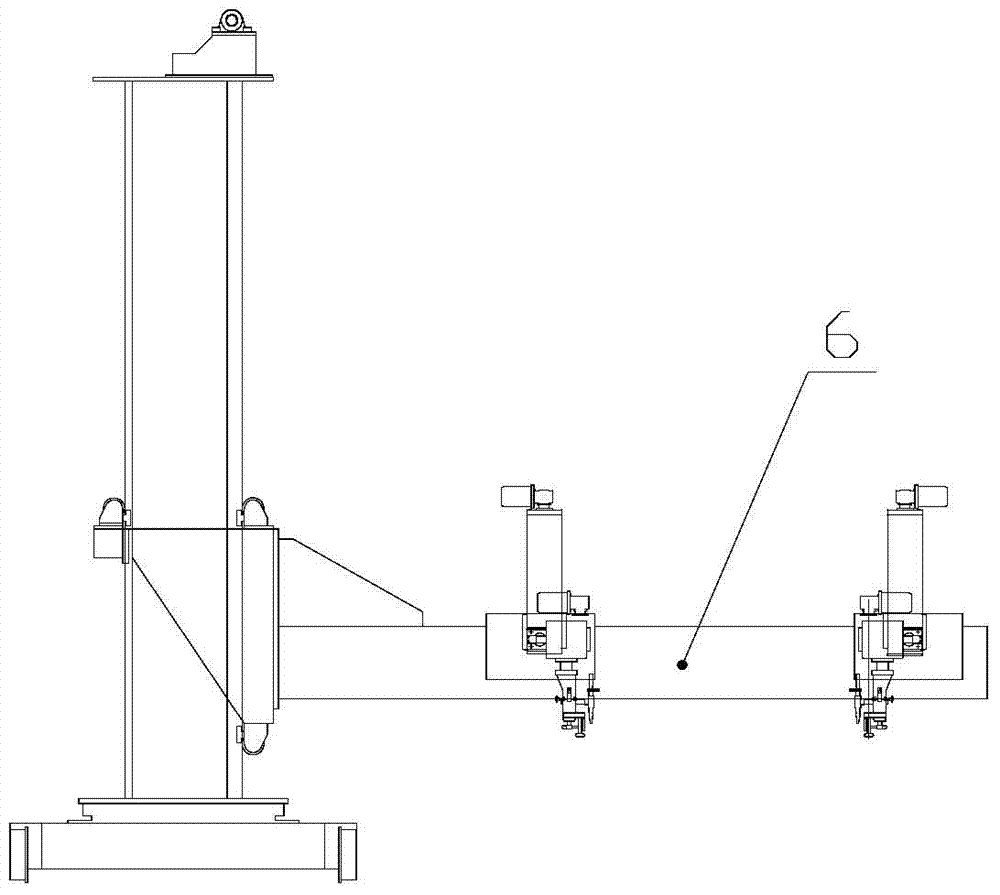

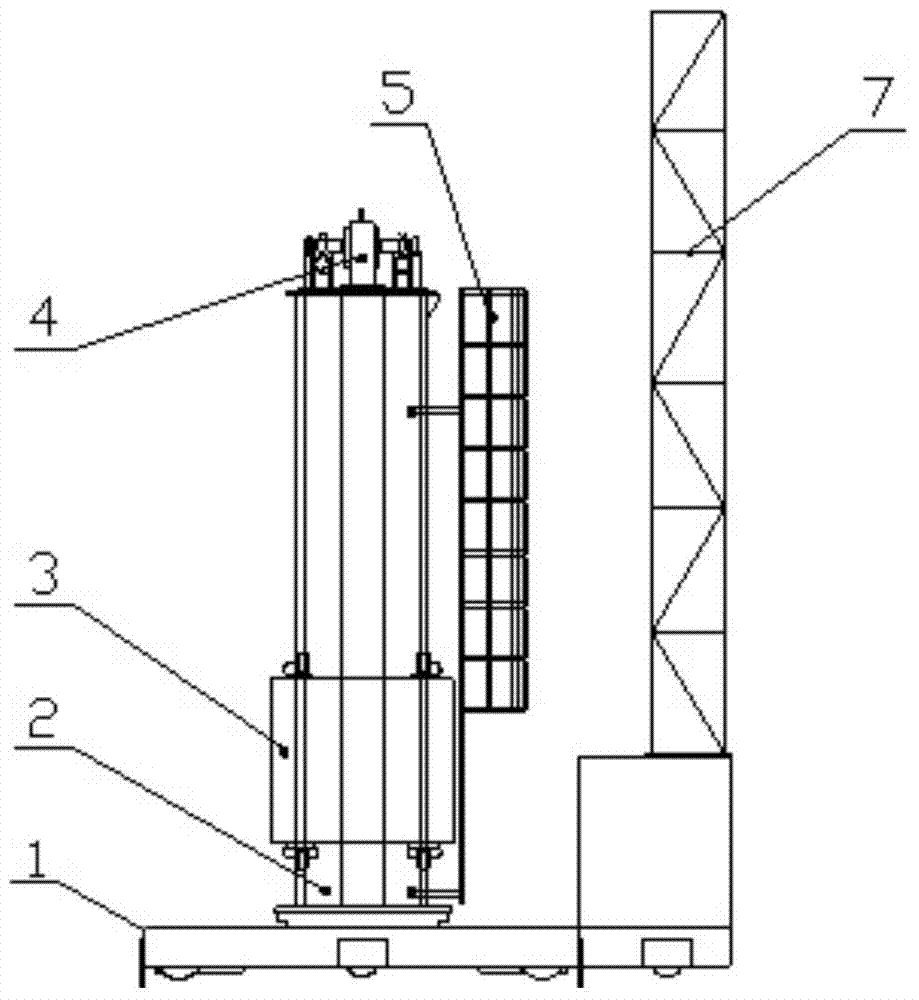

[0041] A kind of box girder welding machine that present embodiment provides, structure such as Figure 1-2 Shown, mainly by trolley part 1, the column mechanism 2 that is installed on the vehicle platform, and the elevating mechanism 4 that is installed on column top and is installed on column one side cantilever component 6, climbing ladder 5 and hanging wire device 7 and forms.

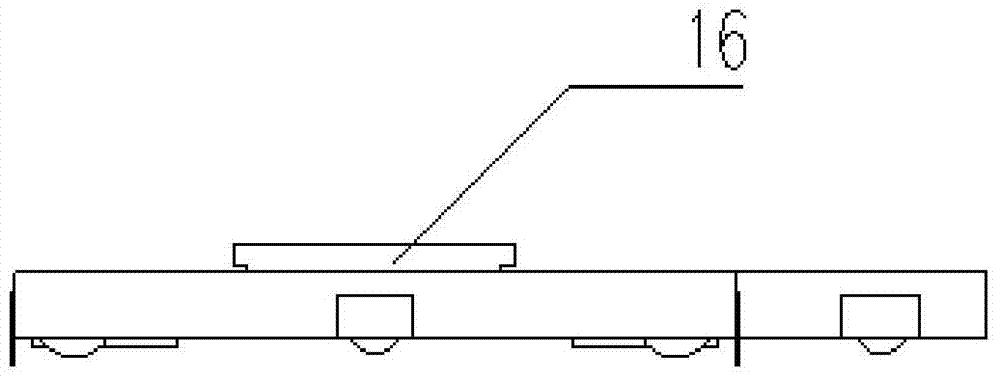

[0042] Such as Figure 3-4As shown, a slewing support 16 is fixed on the frame 14 of the vehicle platform component 1, and the slewing support 16 is used to connect the column mechanism 2. The two ends of the slewing support 16 on the frame 14 are respectively interspersed with a main shaft I15 and a main shaft II17, and the main shaft I15 and The two ends of the main shaft II 17 are respectively provided with seated bearings and walking wheels 11 in sequence, gears are installed on the main shaft I 15 and the main shaft II 17, and a pair of auxiliary wheels 12 are respectively arranged on both sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com