Welding material and welding method for welding transition layer of Ti-pipeline steel composite board

A technology for welding materials and pipeline steel, applied in welding/cutting media/materials, welding media, welding equipment, etc., to achieve the effects of excellent strength and toughness, high welding efficiency, and simplified welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

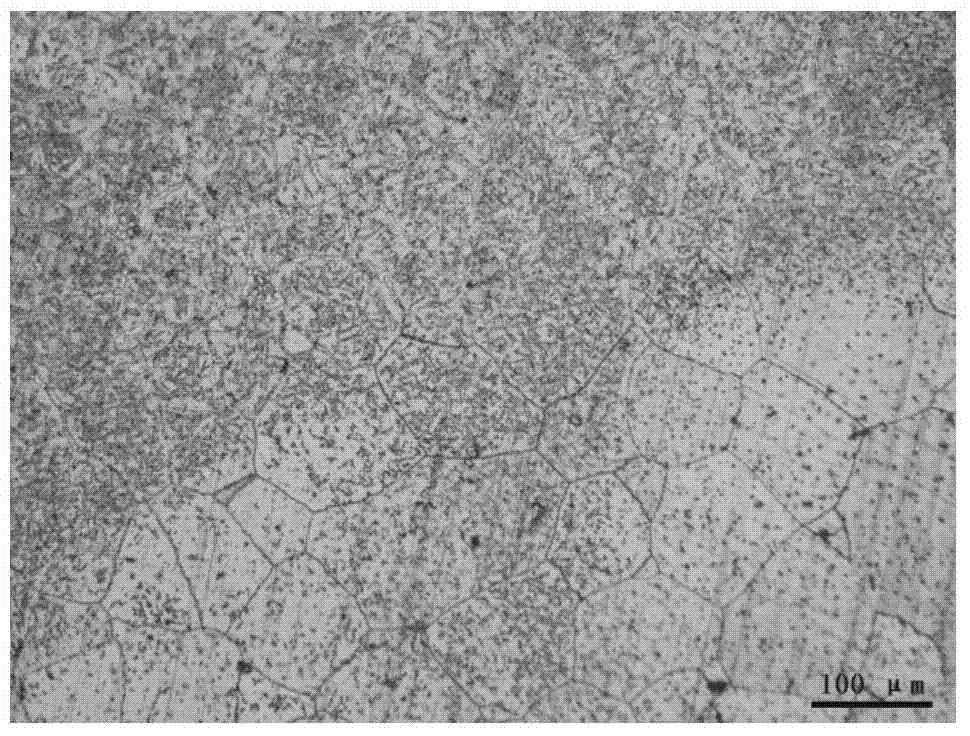

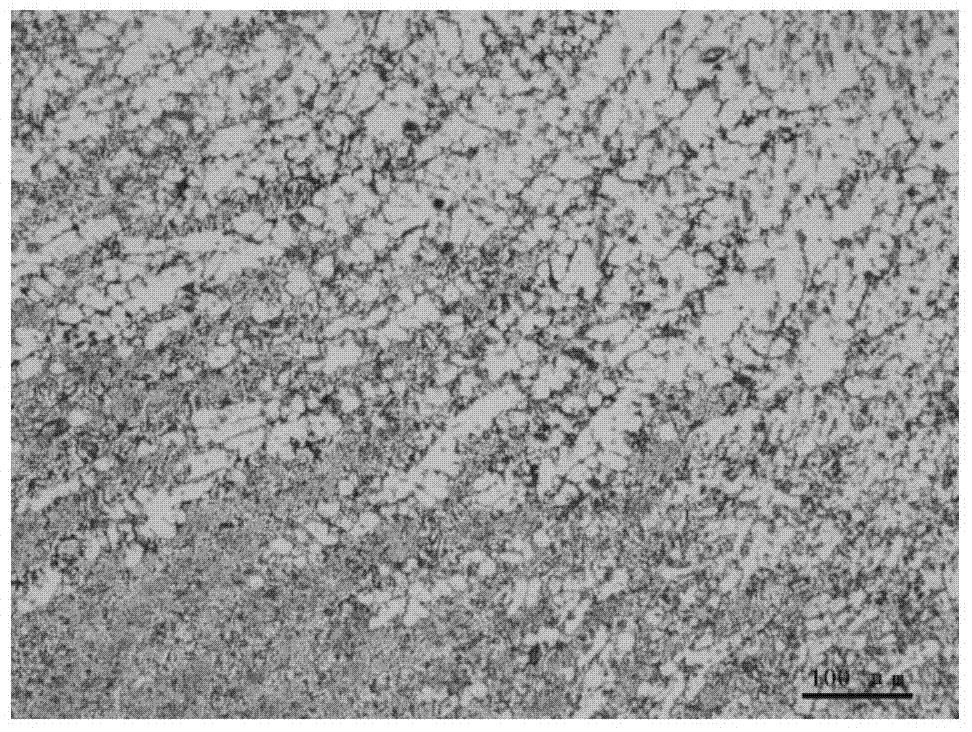

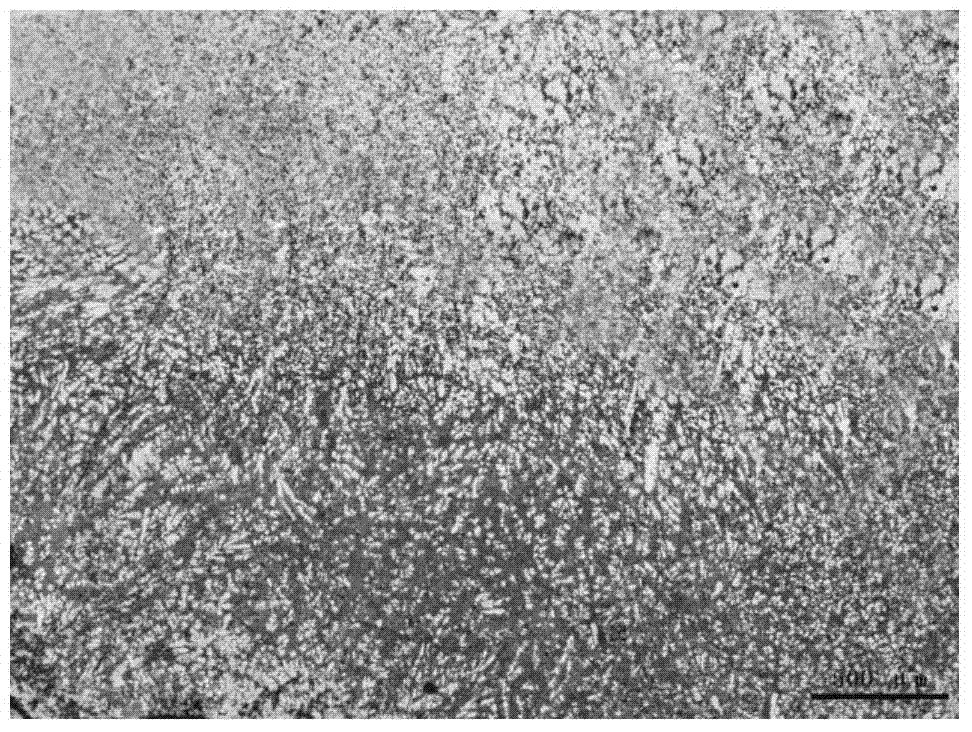

Image

Examples

Embodiment 1

[0032] Step 1. Make a U-shaped groove on the titanium-pipeline steel composite plate. The titanium layer is on the bottom and the steel layer is on the top. The width of the top of the U-groove is 25mm, and then the U-shaped groove is cleaned. And titanium layer cleaning, the process of steel layer cleaning is: first use the angle grinder with grinding wheel to grind the surface of the steel layer, then use the angle grinder with wire brush to grind the side, and then use the angle grinder with sandpaper type grinding wheel to grind the surface of the steel layer. Grind the groove of the steel layer, and then scrub the polished steel layer with acetone to remove surface oxides; the cleaning process of the titanium layer is as follows: first use an angle grinder equipped with a sandpaper-type grinding wheel to grind the surface, side and groove area of the titanium layer , until the polished area has a silver-white metallic luster, and then use HNO 3 - HF-HCl solution to scru...

Embodiment 2

[0039] Step 1. Make a U-shaped groove on the titanium-pipeline steel composite plate. The titanium layer is on the bottom and the steel layer is on the top. The width of the top of the U-groove is 25mm, and then the U-shaped groove is cleaned. And titanium layer cleaning, the process of steel layer cleaning is: first use the angle grinder with grinding wheel to grind the surface of the steel layer, then use the angle grinder with wire brush to grind the side, and then use the angle grinder with sandpaper type grinding wheel to grind the surface of the steel layer. Grind the groove of the steel layer, and then scrub the polished steel layer with acetone to remove surface oxides; the cleaning process of the titanium layer is as follows: first use an angle grinder equipped with a sandpaper-type grinding wheel to grind the surface, side and groove area of the titanium layer , until the polished area has a silver-white metallic luster, and then use HNO 3 - HF-HCl solution to scru...

Embodiment 3

[0046] Step 1. Make a U-shaped groove on the titanium-pipeline steel composite plate. The titanium layer is on the bottom and the steel layer is on the top. The width of the top of the U-groove is 25mm, and then the U-shaped groove is cleaned. And titanium layer cleaning, the process of steel layer cleaning is: first use the angle grinder with grinding wheel to grind the surface of the steel layer, then use the angle grinder with wire brush to grind the side, and then use the angle grinder with sandpaper type grinding wheel to grind the surface of the steel layer. Grind the groove of the steel layer, and then scrub the polished steel layer with acetone to remove surface oxides; the cleaning process of the titanium layer is as follows: first use an angle grinder equipped with a sandpaper-type grinding wheel to grind the surface, side and groove area of the titanium layer , until the polished area has a silver-white metallic luster, and then use HNO 3 - HF-HCl solution to scru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com