A Method of Improving Flow Performance of Lubricating Oil Pump

A lubricating oil pump and performance technology, applied in the field of engine repair, can solve problems such as complex surface structure, increased leakage, low pass rate, etc., and achieve the effect of meeting the technical requirements of use, increasing the flow rate of the lubricating oil pump, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

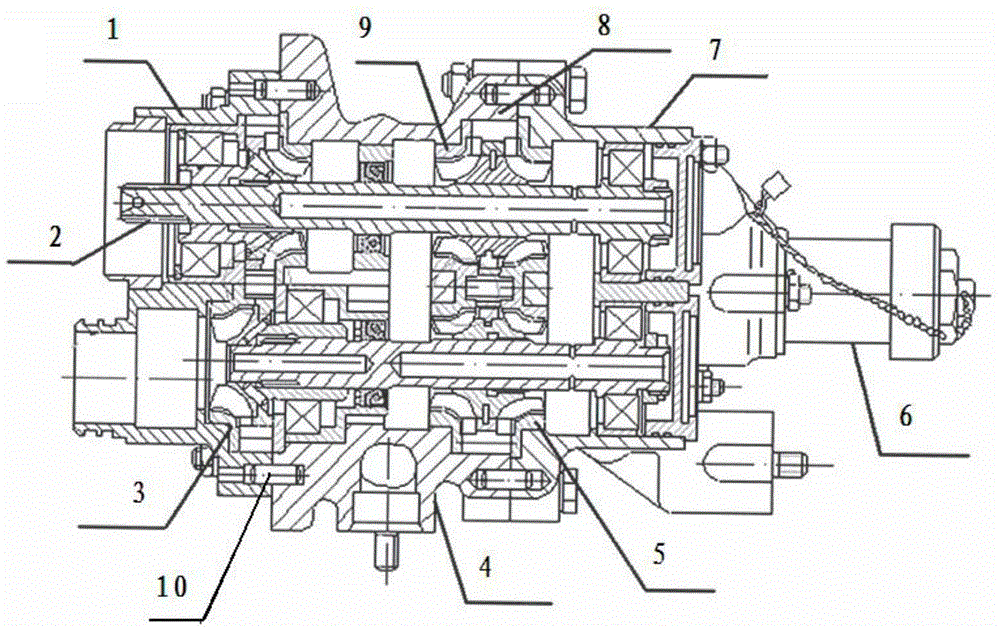

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

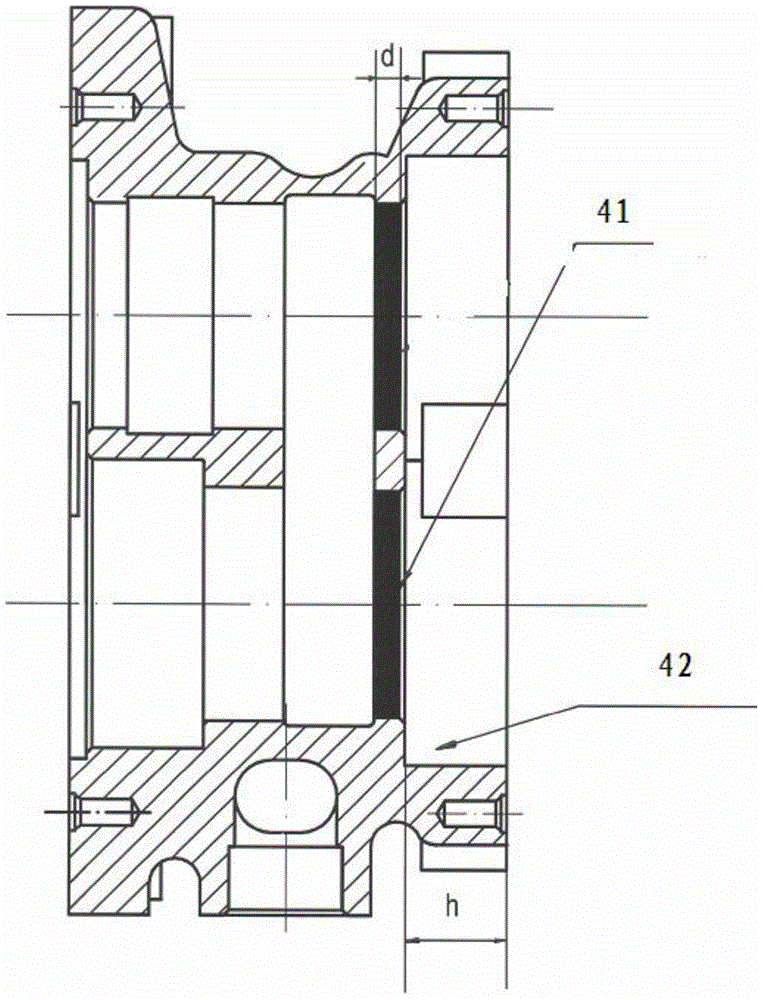

[0020] 1) if figure 1 , figure 2 As shown, the middle casing 4 assembly is reprocessed. Before the reprocessing, the bushing 41 is taken out of the housing hole; then the housing is reprocessed, and the depth h of the gear cavity 42 is deepened by 1 mm. At the same time, the Thickness d of the bushing 41 is reduced by 0.5mm to ensure that the total depth of the gear cavity of the middle casing 4 is deepened by 1.5mm;

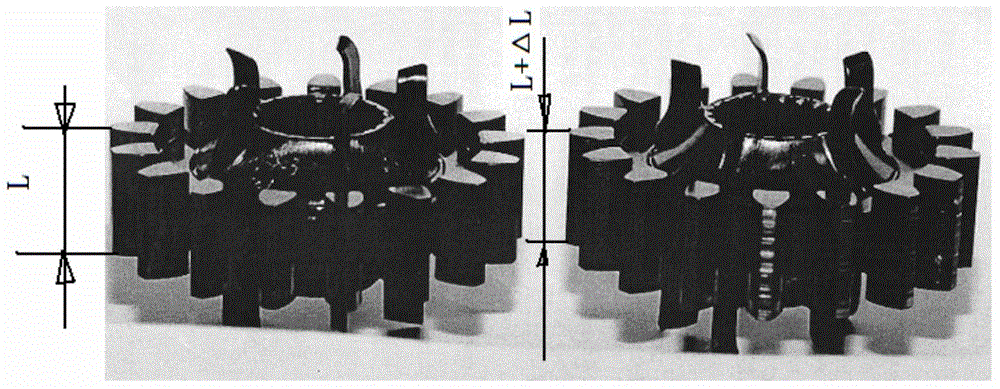

[0021] 2) if image 3 As shown, change the width L of the gear with impeller from 15mm to L+△L=16.5mm;

[0022] 3) Rotate the position of the fixed threaded pin 10 of the middle shell bushing relative to the original fastening position to fasten it by 45 degrees, and fix it by punching; the hole where the threaded pin was originally taken out is blocked with an M4 threaded pin;

[0023] 4) The improved lubricating oil pump is tested on the tester ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com