Welded thin-wall hollow rotor for screw pump and processing method and application thereof

A technology of hollow rotor and processing method, which is applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve the problems of high power of geared motors, heavy weight of solid screws, and high operating noise, so as to reduce vibration intensity and operating costs The effect of low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

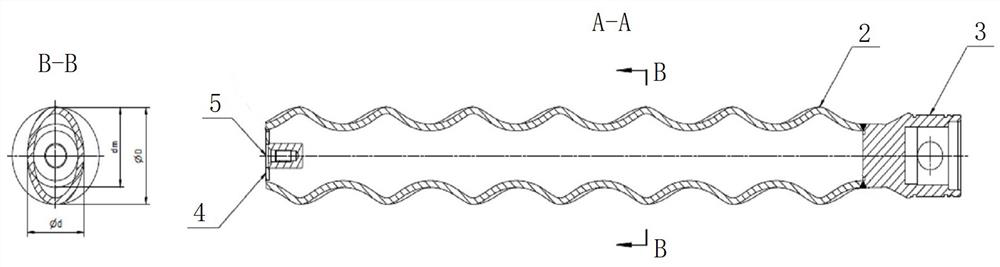

[0042] A method for processing a welded thin-walled hollow rotor for a screw pump, specifically comprising the following steps:

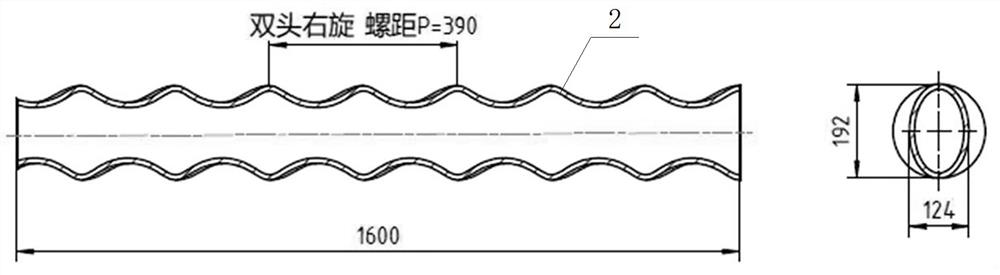

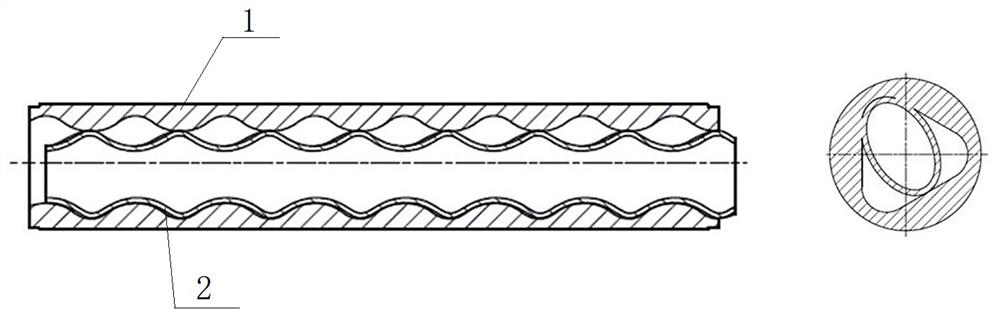

[0043] Step (1). Select a seamless steel pipe with a diameter of 168*12 mm, and process the outer circle to a diameter of 166*10 mm. The process requires a surface roughness of Ra1.6-3.2. The twist-shaped metal special-shaped spiral tube is extruded by the extrusion die on the machine, and the pitch and helical direction are matched with the parameters of the forming helical surface of the inner cavity of the stator used with it;

[0044] Step (2). Weld the matching rotor joints and plug baffles on both ends of the metal special-shaped spiral tube processed in step (1);

[0045] Step (3). Polish the outer surface of the metal special-shaped spiral tube (rotor screw), and the surface roughness reaches Ra1.6-3.2, that is, a welded thin-walled hollow rotor is obtained. The total length of the rotor is 1680 mm (including the length of the rotor screw i...

Embodiment 2

[0047] A method for processing a welded thin-walled hollow rotor for a screw pump, specifically comprising the following steps:

[0048] Step (1). Select a seamless steel pipe with a diameter of 140*10 mm and a surface roughness of Ra1.6-3.2, and extrude the seamless steel pipe through an extrusion die on a press to form a twist-shaped metal special-shaped spiral pipe. And the pitch and the helical direction are all matched with the parameters of the forming helical curved surface of the inner cavity of the stator used in conjunction with it. Because the seamless steel pipe used in the welded thin-walled hollow rotor of this specification happens to have a commercial specification of 140*10mm, so there is no need to do surface cutting, and it can be used directly by extrusion.

[0049] Step (2). Weld the matching rotor joints and plug baffles on both ends of the metal special-shaped spiral tube processed in step (1);

[0050] Step (3). Polish the outer surface of the metal sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com