Poly ethylene terephthalate (PET) bottle sterilization box

A sterilizing box and shell technology, applied in the field of PET bottle filling, can solve the problems of strange smell, incomplete sterilization, physical discomfort, etc., achieve the effect of simple structure and reduce the risk of external pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

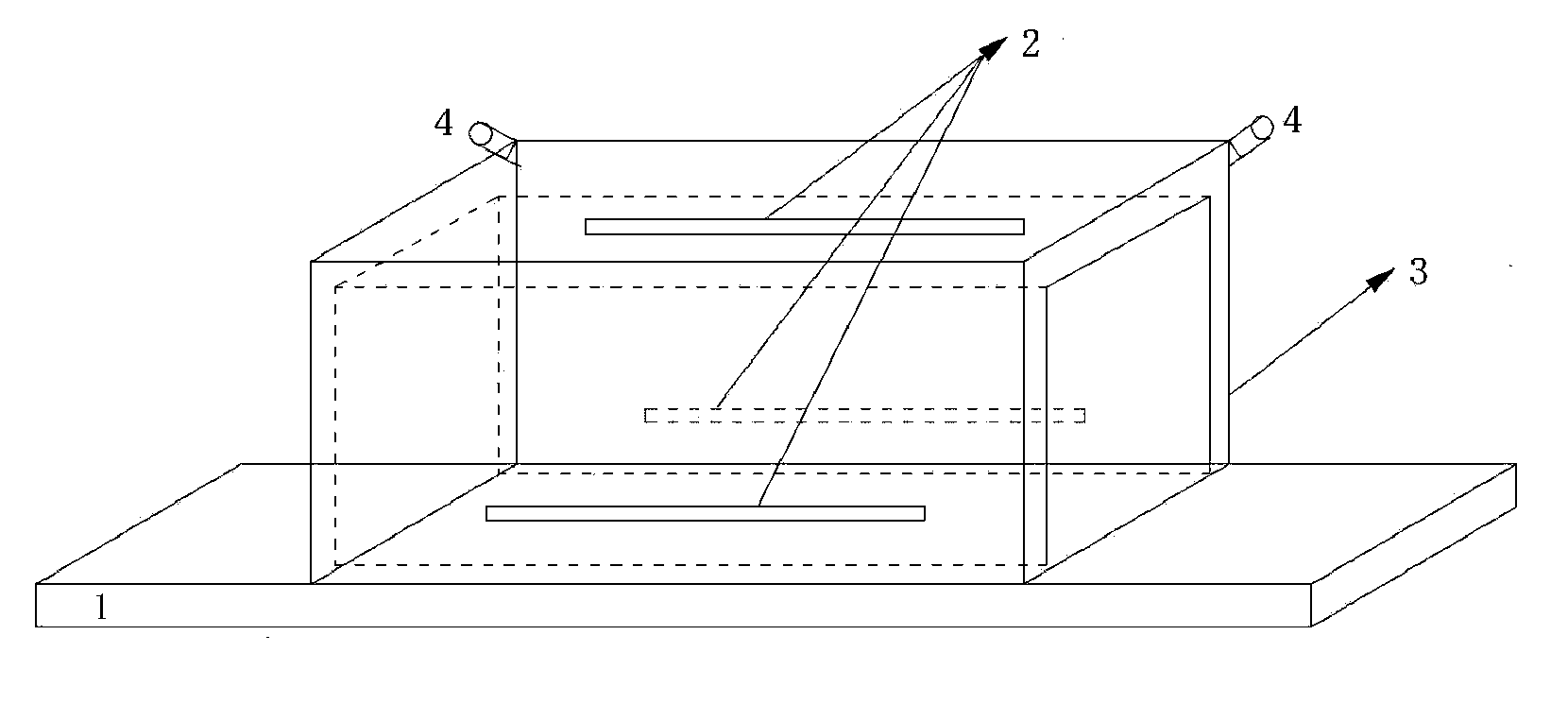

[0016] The top and both sides of the housing 3 are respectively equipped with an ultraviolet lamp with an ultraviolet wavelength of 253.7nm and a length of 740mm. Anti-ultraviolet diffusion curtains are installed at both ends of the housing 3, and the sterilization time is controlled by the speed of the belt conveyor line 1. The cover on the top of the housing 3 can be opened, which is convenient for maintenance and lamp tube replacement. The housing 3 is made of stainless steel.

[0017] The PET bottle enters the shell 3 through the belt conveyor line 1, and the ultraviolet light emitted by the ultraviolet lamp 2 installed on the shell 3 is used to sterilize the PET bottle entering the shell 3, and the speed of the motor at both ends of the belt conveyor line 1 is adjusted to control the PET bottle. The time of staying in the shell 3, so as to achieve the sterilization effect on PET bottles. When the service life of the ultraviolet lamp 2 expires, the switch 4 is turned off,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com