Preparation method of ammonia borane (NH3BH3)

A technology of ammonia borane and borane, which is applied in the field of preparation of ammonia borane, can solve problems such as complex equipment and operation, and achieve the effects of moderate cost, simple synthesis process and operation, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

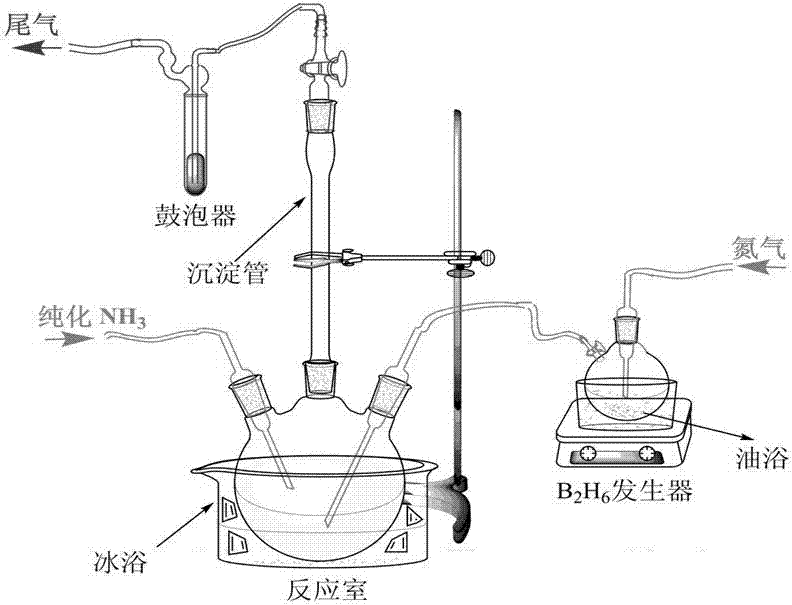

[0019] 1. Preparation of NH in small batches 3 BH 3 device

[0020] Preparation of NH in small batches in the laboratory 3 BH 3 Available figure 1 The device, the reaction chamber is a three-necked flask, the left and right sides are inlets for ammonia gas and borane gas respectively, the middle branch of the three-necked flask is connected to a settling tube, and the settling tube is connected to a bubbler. The three-neck flask was placed in an ice bath to control the reaction temperature. Ammonia uses dry pure ammonia, and borane is produced on-site by the generator. During the reaction, the material placed in the generator is heated by an oil bath to release borane gas, which is taken out of the generator by nitrogen and then enters a three-necked bottle to react with the ammonia gas introduced to prepare ammonia borane. After the reaction is finished, the settling tube and the outlet valve of the borane generator are closed, and the reaction chamber is evacuated thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com