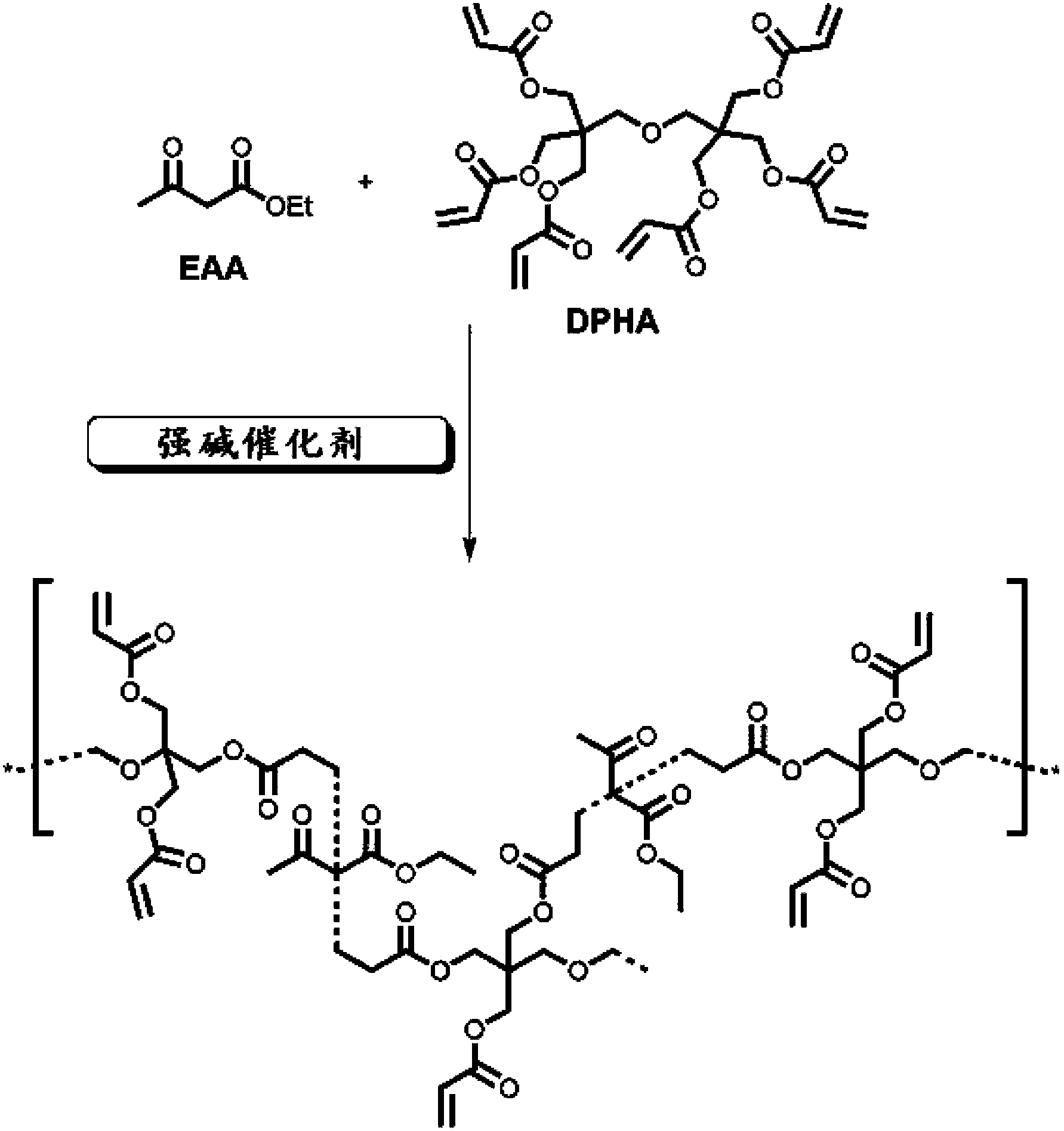

Self-sensitive polymerizable liquid resin and use thereof

一种液体树脂、光聚合的技术,应用在聚酯涂料、聚脲/聚氨酯涂料、涂层等方向,能够解决无法成为液态等问题,达到避免树脂胶化、良好辐射固化性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

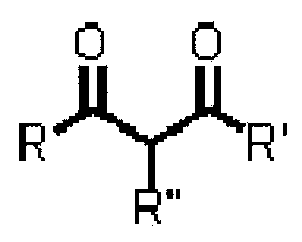

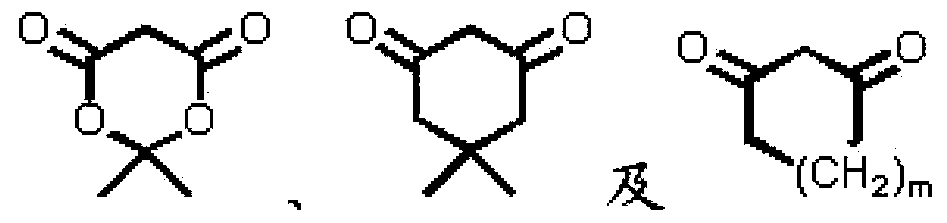

Method used

Image

Examples

preparation example 1

[0097] Take 373 grams of trifunctional acrylate monomer (EM235-1 provided by Eternal Company) and 0.57 grams of catalyst DBTL (dibutyltin dilaurate, ACROSCHEMICALS) and mix them in a four-necked flask at room temperature under nitrogen, and mix trifunctional isocyanate (provided by Bayer Company) After adding 200 grams of Desmodur XP2580) slowly, the temperature was raised to 75° C. and reacted for eight hours to obtain 573 grams of the final nine-functional acrylate monomer. Weight average molecular weight (Mw) measured by gel permeation chromatography (GPC) (model: Waters2414RI): 1,390.

Embodiment A-1

[0100] Take 2800 grams of hexafunctional acrylate monomer (EM265 provided by Eternal Company) and catalyst DBU (1,8-Diazabicyclo[5.4.0]undec-7-ene, ACROS CHEMICALS) 9.25 grams (0.05 equivalent of EAA) and mix Stir in a four-necked flask at room temperature, add 158 g (0.25 equivalent) of Mike donor (EAA, ACROS CHEMICALS) and raise the temperature to 95°C for six hours to obtain 2960 g of the final resin (HSY-703).

Embodiment A-2

[0102] Get 500 grams of hexafunctional acrylate monomer (EM265 provided by Eternal Company) and catalyst DBU (1,8-Diazabicyclo [5.4.0] undec-7-ene, ACROSCHEMICALS) 2.63 grams (0.05 equivalent of EAA) mixed in Stir in the four-neck flask at room temperature, add 45 g (0.4 equivalent) of Mike donor (EAA, ACROS CHEMICALS) and raise the temperature to 95° C. for six hours to obtain 545 g of the final resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com