Weak acid acidizing fluid for water injection well with non-moving string and preparation method thereof

A technology for acidizing fluid and water injection well, which is applied in the directions of chemical instruments and methods, drilling composition, etc., can solve the problems of affecting the energy replenishment of oil production wells, delaying construction time, and multi-manpower and material resources, so as to delay secondary scaling. The effect of plugging, increasing injection volume and reducing displacement pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The invention discloses a weak-acid acidification liquid formula for a non-moving pipe string for water injection wells, which comprises the following component proportions by weight percentage: acid liquid: 10-30%; stabilizer: 2-8%; corrosion inhibitor: 1~5%; surfactant: 6.5~17%; the rest is distilled water.

[0041] The weak acid acidification solution can be prepared by conventional heating and stirring method in this field.

Embodiment 2

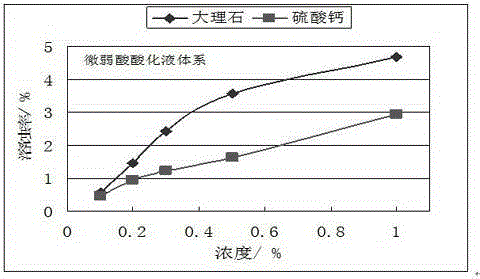

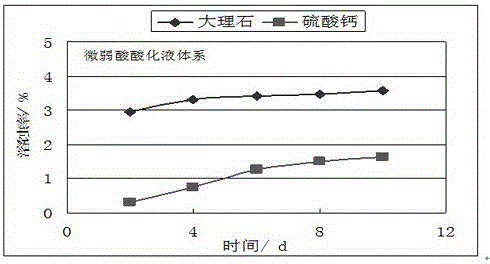

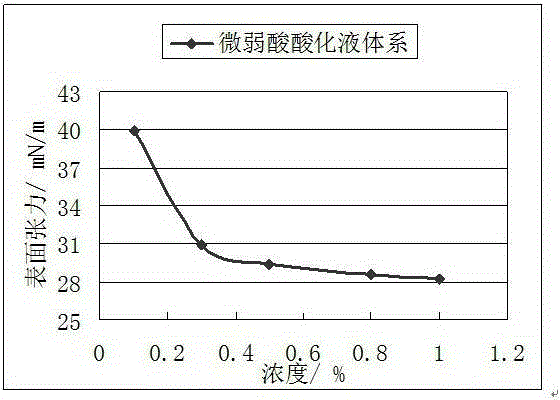

[0043]On the basis of Example 1, a more preferred embodiment of the present invention is: the acid solution is one or more of succinic acid and (PBTCA, HPAA, BHMTPMPA, HDTMPA), wherein the weight percentage of succinic acid is 5~10%, (PBTCA, HPAA, BHMTPMPA, HDTMPA) one or several weight total percentages are 5~20%, (PBTCA, HPAA, BHMTPMPA, HDTMPA) are all produced by Shandong Taihe Water Treatment Co., Ltd. The stabilizer is citric acid and ascorbic acid, wherein the weight percentage of citric acid is 1-3%; the weight percentage of ascorbic acid is 1-5%. The corrosion inhibitor is propynol, and its weight percentage is 1-5%. The surfactants are alcohol ether carboxylic acid (AEC-9), octylphenol polyoxyethylene ether and fluorocarbon surfactant, wherein the weight percentage of alcohol ether carboxylic acid (AEC-9) is 5-10%, The weight percentage of octylphenol polyoxyethylene ether is 1-5%, and the weight percentage of fluorocarbon surfactant is 0.5-2%. The fluorocarbon surfa...

Embodiment 3

[0045] Material preparation, based on the weight percentage of the weak acid acidification solution, each component is prepared according to the following weight: succinic acid: 5~10%; alcohol ether carboxylic acid (AEC-9): 5~10%; citric acid: 1~3% %; ascorbic acid: 1~5%; propynyl alcohol: 1~5%, fluorocarbon surfactant: 0.5~2%, octylphenol ethoxylate: 1~5%; (PBTCA, HPAA, BHMTPMPA, HDTMPA ) in one or more: 5~20%; the rest is distilled water.

[0046] First add all the distilled water into the reaction kettle, and raise the temperature to 50-55°C; then, add all the succinic acid and one or more of (PBTCA, HPAA, BHMTPMPA, HDTMPA), and stir for 20-30 minutes; then, add All the citric acid and ascorbic acid, stir for 20-30 minutes; then, add all the propynyl alcohol, stir for 15-20 minutes; finally, add all the alcohol ether carboxylic acid (AEC-9), fluorocarbon surfactant and octylphenol Polyoxyethylene ether, stirred for 20 to 30 minutes, to produce a weak acid acidification liq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com