Immobilization method of penicillium citrinum

A technology of Penicillium citrinum, immobilized medium, applied in microorganism-based methods, biochemical equipment and methods, immobilized on/in organic carriers, etc., to achieve high mechanical strength, high mass transfer efficiency, good mass transfer performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

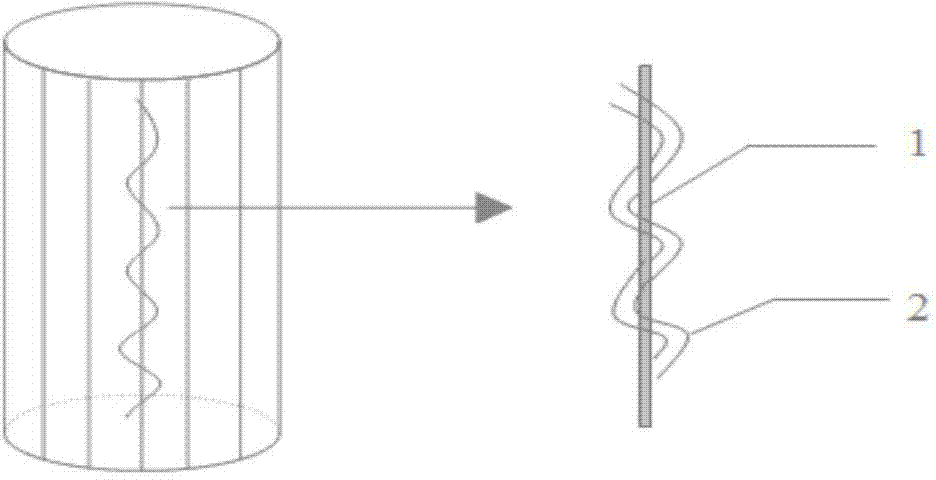

[0027] Example 1: Preparation of fibrous material immobilization medium.

Embodiment approach

[0029] (1) Boil the fiber material in boiling water for 0.1-5 hours and then dry it at 20-100 °C;

[0030] (2) Soak the fiber material in a surface modifier aqueous solution with a concentration of 1-100g / L for 1-20 hours, and adjust the pH of the solution to 7.0 with hydrochloric acid, and then place the fiber material in deionized water for full rinsing for 60 hours. -80℃ drying;

[0031] (3) Soak the fiber material in a cross-linking agent aqueous solution with a concentration of 1-100g / L for 1-20 hours, then fully rinse the fiber material in deionized water, dry it at 60-80°C, and store it at 4°C for later use ;

[0032] The surface modifier is any one or more of polyethyleneimine, polyetherimide, succinimide, diethylenetriamine and dimethylaminopropylamine; the crosslinking agent It is any one or more of glutaraldehyde, glyoxal, succinic aldehyde, 2-methyl-1,3-propanedialdehyde and (2S,3R)-2,3-dihydroxybutanedialdehyde.

[0033] For example, the following specific prep...

Embodiment 2

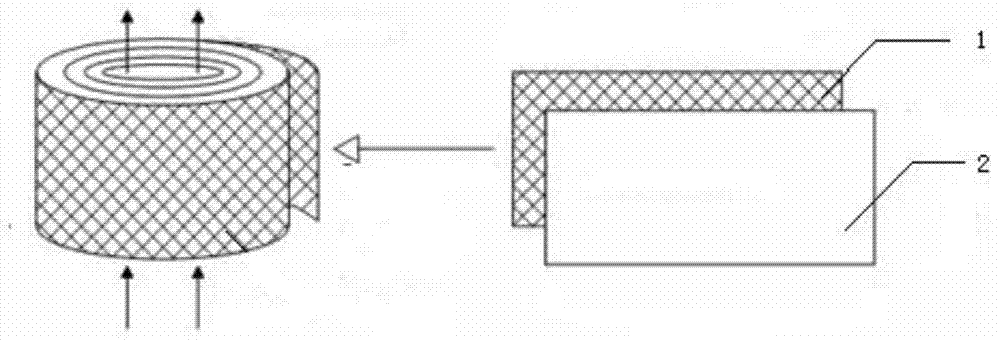

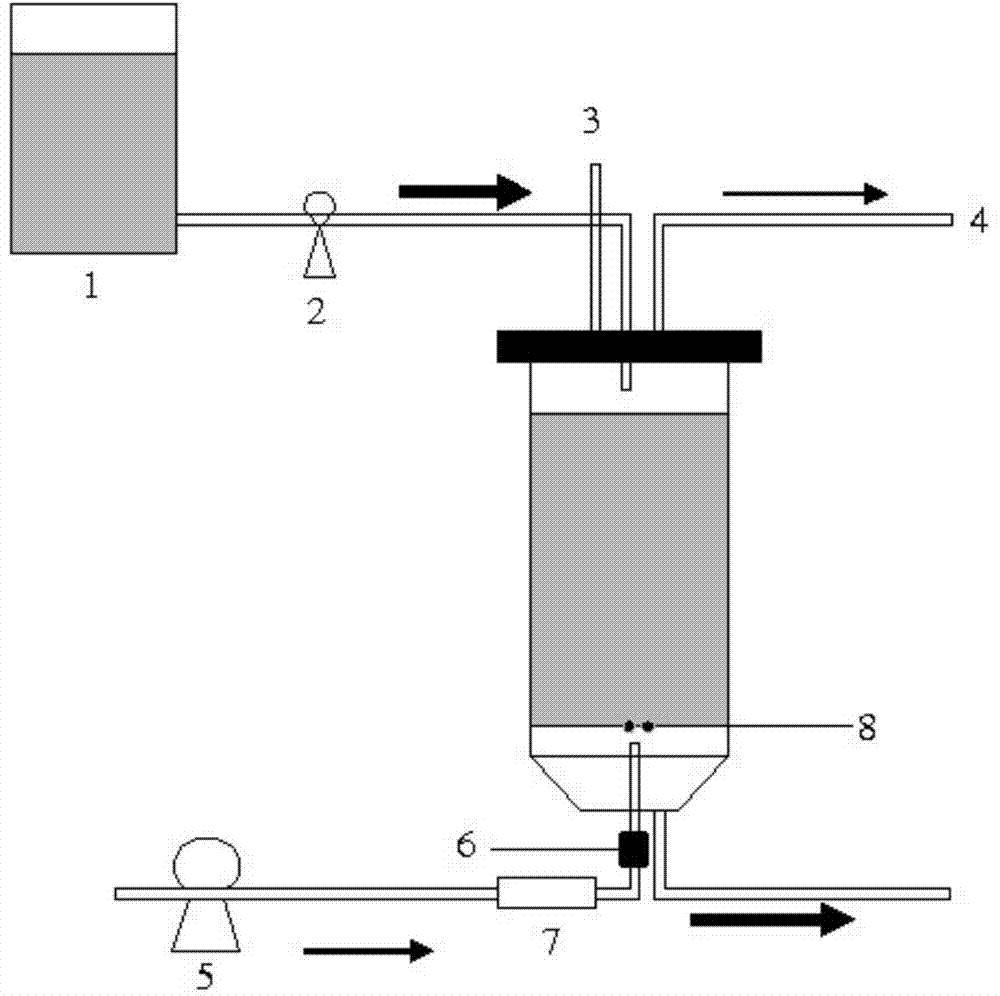

[0047] Example 2: Production of nuclease P1 in shake flasks using activated carbon fiber immobilization medium.

[0048] The activated carbon fibers were pretreated according to the method described in Mode 1 in Example 1, and the treated activated carbon fibers were flattened on a traveler with a diameter slightly smaller than the diameter of the triangular flask with an addition amount of 50 g / L, and fixed as a shaker flask. Immobilization medium for the production of nuclease P1 by immobilization and fermentation.

[0049] The Penicillium citrinum strain was cultured on the wort slant at 28-30°C for 5-7 days for activation, and the Penicillium citrinum slant was fully washed with sterile water to obtain a spore suspension, which was transferred to 100 mL of liquid fermentation medium (components: Glucose 50g / L, Peptone 5g / L, Potassium Dihydrogen Phosphate 0.04g / L, Dipotassium Hydrogen Phosphate 0.04g / L, Magnesium Sulfate 0.05g / L, Calcium Chloride 0.05g / L, Zinc Sulfate 0.05g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com