Method for reducing clear juice color value in sugar-making process by sulfurous method

A juice clearing and crafting technology, applied in sugar production, sugar products, sucrose production, etc., can solve problems such as high cost, and achieve the effect of inhibiting color enhancement and color value reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

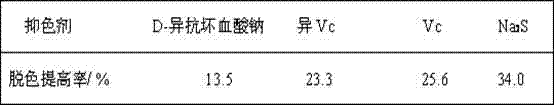

[0025] Example 1: Add 100 g of sugarcane mixed juice and 0.015 g of color suppressant to a 250 mL beaker, then adopt the sulfurous acid clarification procedure to decolorize the mixed juice. Put the beaker on a magnetic constant temperature stirrer, start heating and stirring at the same time, the stirring speed is 100-120 R / min, then add calcium oxide to adjust the pH value to 6.8-7.2, then heat the water bath to 70°C, and then add the remaining calcium oxide , the total amount of calcium oxide added is 0.25g, stir for 2-3 minutes to dissolve the calcium oxide, adjust the pH value to 6.9-7.1 with sulfurous acid, continue stirring at a low speed of 40-60 R / min for 10 minutes, and then let it stand for 30 minutes. Then filter with qualitative filter paper to get clear juice. See attached table 1 for the decolorization improvement rate of each color suppressor.

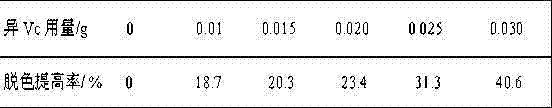

[0026] Schedule 1

[0027]

Embodiment 2

[0028] Embodiment 2: After adding 100g of sugarcane mixed juice and a certain amount of iso-Vc in a 250 mL beaker, the mixed juice is decolorized by using the sulfite clarification process. The specific steps are: the beaker containing the sugarcane mixed juice and iso-Vc Put it on a magnetic constant temperature stirrer, turn on heating and stirring at the same time, the stirring speed is 100-120 R / min, then add calcium oxide to adjust the pH value to 6.8-7.2, then heat the water bath to 70°C, and then add the remaining calcium oxide, The total amount of calcium oxide added is 0.25g. Stir for 2-3 minutes to dissolve the calcium oxide and adjust the pH value to 6.9-7.1 with sulfurous acid. Continue stirring at a low speed of 40-60 R / min for 10 minutes, then let it stand for 30 minutes, and then Filter with qualitative filter paper to get clear juice.

[0029] Get 100g sugarcane mixed juice again and do the blank test corresponding to embodiment 2, the clear juice that blank te...

Embodiment 3

[0033] Embodiment 3: Get 4 parts of 100g sugarcane mixed juice, after adding a certain amount of sodium vitamin C, then adopt the sulfite method to clarify the process to decolorize the mixed juice, the specific steps are: first add 0.35g calcium hydroxide, stir to dissolve, and then Add 200ppm phosphoric acid and 3mL sulfurous acid saturated solution, stir evenly, react for 25min, add flocculant polyacrylamide 5ppm after heating to 100°C, flocculate and settle, filter through microporous to obtain clear juice, and measure the color value.

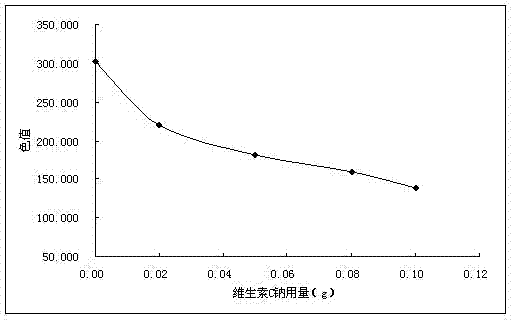

[0034] Get 100g sugarcane mixed juice again and do the blank test corresponding to embodiment 3, the clear juice that blank test obtains and the vitamin C sodium that adds different amounts obtain clear juice color value curve chart see figure 1 .

[0035] As a transformation of Example 3, the calcium hydroxide can also be replaced by calcium oxide, and the amount of calcium oxide added is based on 0.23-0.30 g of 100 g of sugarcane mixed j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com