Sugar-making clarification process

A technology, dextranase technology, applied in sucrose production, sugar production, sugar juice purification, etc., can solve the problems of excessive sulfur dioxide residue in white granulated sugar, affect product quality, increase production cost, etc., and achieve good market prospects , reduce the color value of sugar paste and improve the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

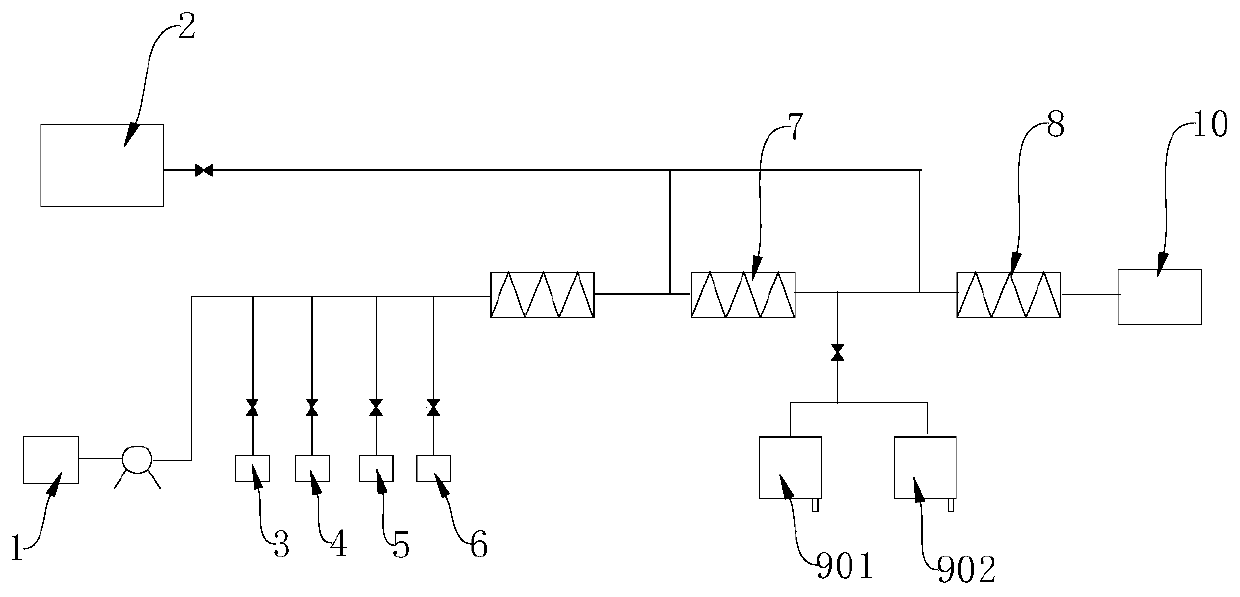

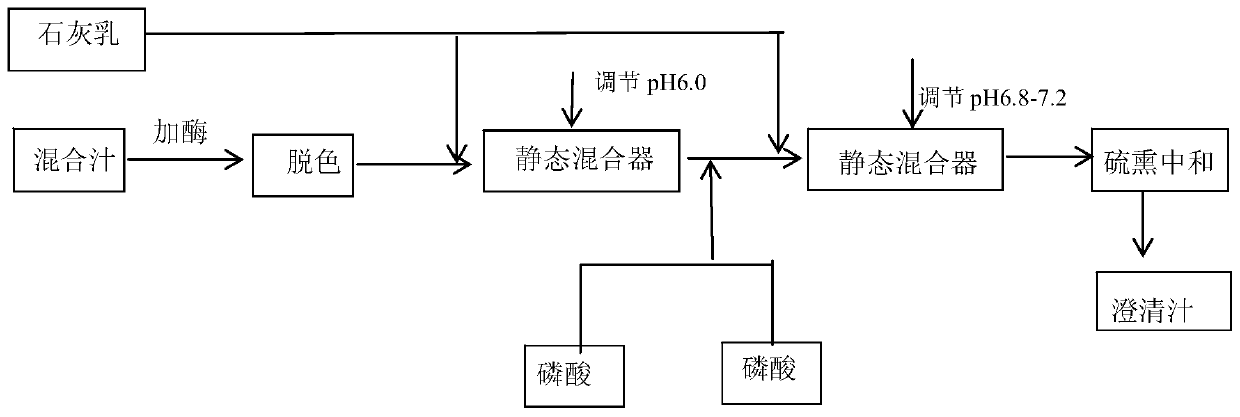

[0034] The production system adopted in the preparation process of the present invention includes a mixed juice tank 1, a static mixer I7, a static mixer II8 and a sulfur fumigation device 10 connected in sequence. Mixed juice tank 1 is connected with static mixer I7 through pipelines, and is connected with enzyme tank I3, enzyme tank II4, -enzyme tank III5 and enzyme tank IV6.

[0035] The milk of lime tank 2 is respectively connected with the pipeline at the inlet of the static mixer I7 and the inlet of the static mixer II8. At the inlet of the static mixer I7, a metering pump is used to quantitatively add the milk of lime and transport it to the static mixer I7 for mixing. , adjust the pH to 6.0. Phosphoric acid tank I901 and phosphoric acid tank II902 are connected with the outlet of static mixer I7, and phosphoric acid is added quantitatively at the outlet of static mixer I with a metering pump, and lime is quantitatively added at the inlet of static mixer II with a meter...

Embodiment 1

[0038] A sugar clarification process, comprising the following steps:

[0039] S1. Decolorization treatment:

[0040] The sugarcane is squeezed and extracted to obtain mixed juice, and polyphenol oxidase and anthocyanidase are added to the mixed juice for decolorization treatment to obtain the enzyme-added mixed juice.

[0041] The usage amount of the polyphenol oxidase is 0.5U / mL mixed juice; the usage amount of the anthocyanidase is 0.2U / mL mixed juice.

[0042] S2. Pre-ash:

[0043] adding milk of lime and phosphoric acid to the enzyme-added mixed juice for prelime treatment to obtain prelime juice;

[0044] The prelime treatment is to firstly add lime milk to adjust the pH of the enzyme-added mixed juice to 6.0; then add phosphoric acid, and then add lime milk to adjust the pH to 7.0.

[0045] The amount of phosphoric acid added is 250ppm of the weight of the enzyme mixed juice.

[0046] S3. Neutralization by sulfur fumigation:

[0047] The prelime juice is neutralize...

Embodiment 2

[0049] A sugar clarification process, comprising the following steps:

[0050] S1. Decolorization treatment:

[0051] The sugarcane is squeezed and extracted to obtain mixed juice, and polyphenol oxidase and anthocyanidase are added to the mixed juice for decolorization treatment to obtain the enzyme-added mixed juice.

[0052] The usage amount of the polyphenol oxidase is 0.1U / mL mixed juice; the usage amount of the anthocyanidase is 0.1U / mL mixed juice.

[0053] S2. Pre-ash:

[0054] adding milk of lime and phosphoric acid to the enzyme-added mixed juice for prelime treatment to obtain prelime juice;

[0055] The prelime treatment is to firstly add milk of lime to adjust the pH of the enzyme-added mixed juice to 6.0; then add phosphoric acid, and then add milk of lime to adjust the pH to 6.8.

[0056] The amount of phosphoric acid added is 350ppm of the weight of the enzyme mixed juice.

[0057] S3. Neutralization by sulfur fumigation:

[0058] The pre-lime juice is neutr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com