Braking system of wind driven generator and braking method

A technology for wind turbines and braking systems, which is applied in the control of wind turbines, wind turbines, and wind power generation, etc., can solve the problems of wind turbines failing to generate electricity, power consumption of brake discs, and shocks, so as to improve the effective utilization rate, The effect of avoiding power consumption and preventing the system from being impacted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments will be described in detail below with reference to the accompanying drawings, these specific embodiments are only for explaining the working principle of the present invention, and do not mean that the present invention is limited to these specific embodiments.

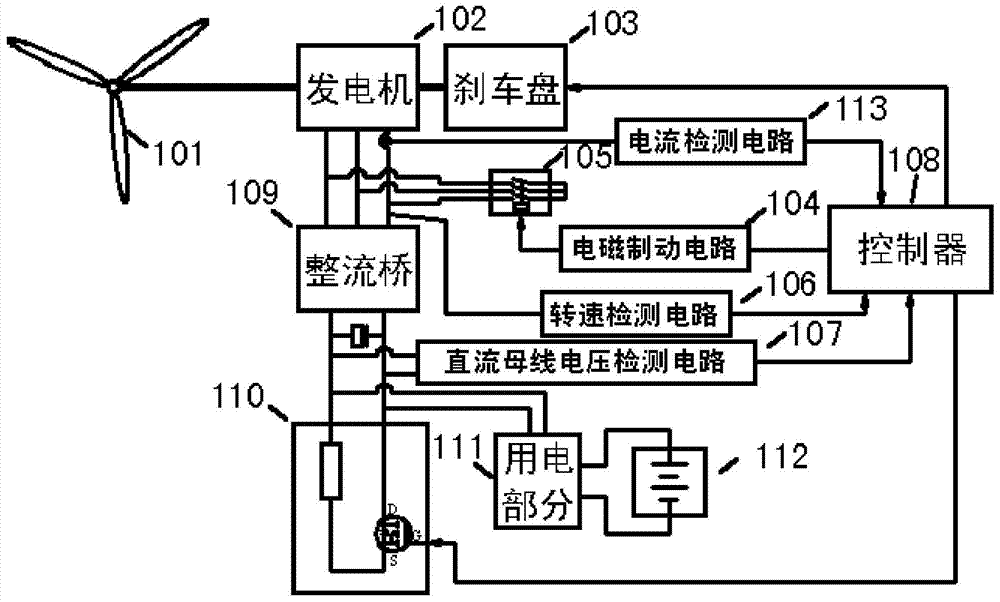

[0032] figure 1 Illustrating the overall schematic block diagram of the braking system of the wind power generator according to an embodiment of the present invention, the names and functions of the various components are listed below, wherein,

[0033] Wind wheel 101: It is a component that converts wind energy into rotational kinetic energy, and it is composed of blades and a hub.

[0034] Generator 102: It is a component that converts the rotational kinetic energy of the wind wheel 101 into electrical energy.

[0035] Brake disc 103. It is a kind of mechanical braking part: it is a component that brakes the generator mechanically. It generates a magnetic field by energizing the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com