Stove for combined combustion of liquefied petroleum gas and methanol

A liquefied petroleum gas, two-in-one technology, applied in household stoves/stoves, lighting and heating equipment, etc., can solve the problems of increased combustion costs, large demand, environmental pollution, etc., and achieve high fuel combustion efficiency and stable combustion flames , Easy to install and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

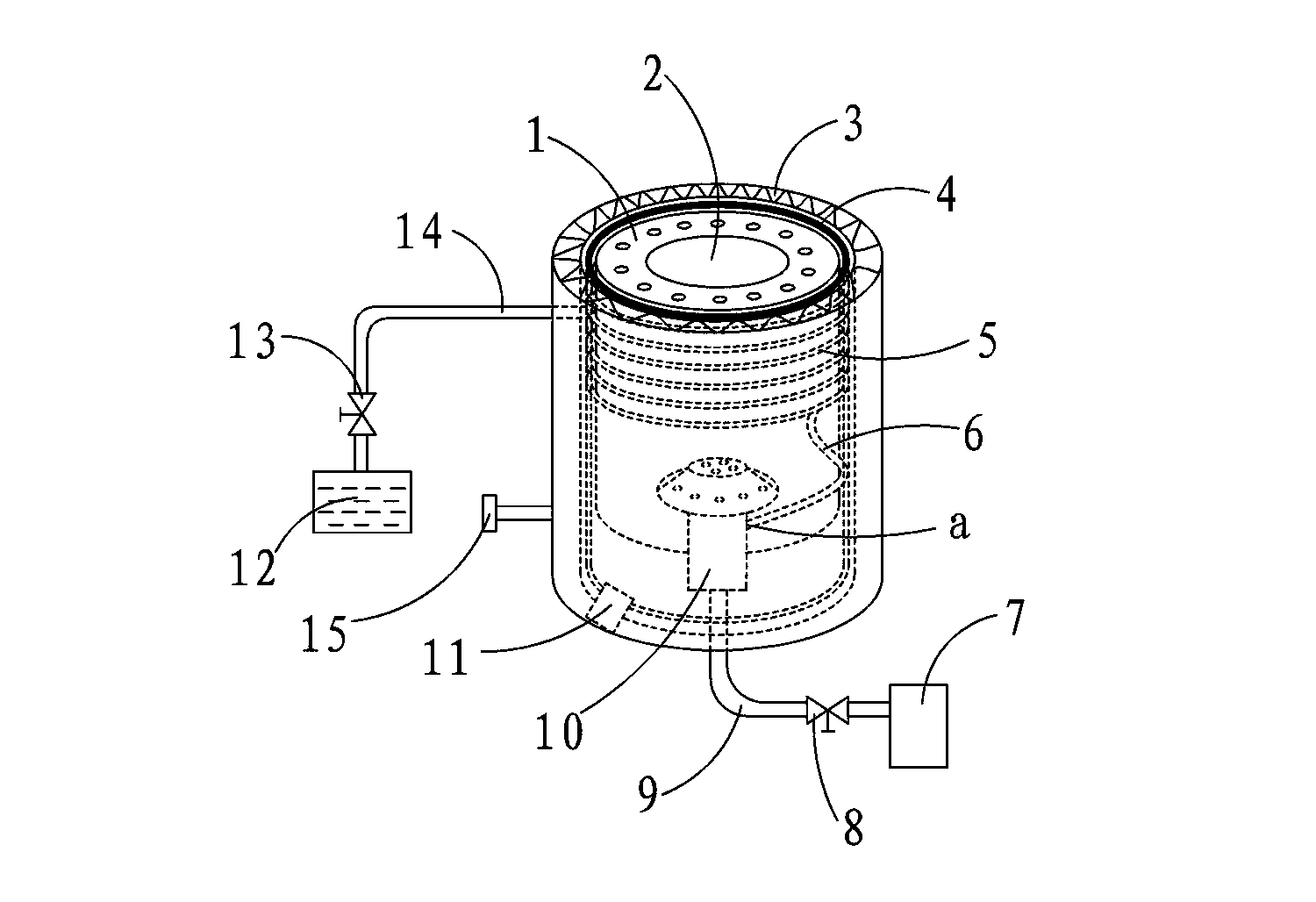

[0013] Such as figure 1 As shown, the methanol stove with improved structure is mainly composed of a furnace body 1, an insulating layer 3 surrounding the furnace body 1, a copper tube 5 wound on the outer wall of the furnace body 1, and a furnace core located at the center of the furnace body 1 to burn Chamber 10 is composed.

[0014] A layer of heat insulation layer 4 may also be provided between the furnace body 1 and the insulation layer 3 to prevent the heated copper tube 5 from diffusing heat outward, so as to ensure that sufficient heat is stored in the copper tube 5 .

[0015] The lower end of the furnace core combustion chamber 10 is connected with the petroleum liquefied gas hose 9, and the petroleum liquefied gas hose 9 is provided with a gas control valve 8; the lower end of the furnace core combustion chamber 10 is also provided with a methanol gas pipeline inlet a, and the furnace core burns A plurality of gas shower heads 2 are arranged inside the chamber 10, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com