Photoinduced deformation thin film reflector surface shape control and measurement device

A thin-film mirror and photodeformation technology, applied in the field of space optics, can solve the problems of poor surface shape control accuracy, low system reliability, and complex system, and achieve the effect of high surface shape control accuracy and improved reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

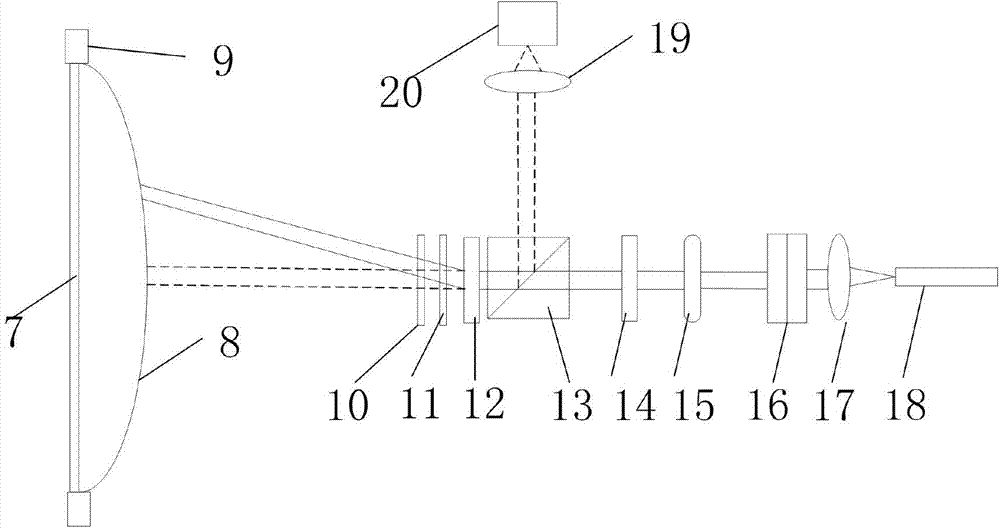

[0023] Such as figure 2 As shown, the surface shape control and measuring device of the photodeformable film mirror of the present invention includes a film support frame 7, a photodeformable film 8, a film boundary displacement controller 9, a birefringent prism 10, a polarization rotator 11, a liquid crystal Spatial light modulator 12, beam splitting prism 13, polarization state controller 14, free space optical isolator 15, intensity phase modulator 16, first laser collimating mirror 17, laser 18, second laser collimating mirror 19 and photoelectric detection device 20.

[0024] The film support frame 7 fixes the periphery of the photodeformable film 8 and keeps it in a flat state, and the film boundary displacement controller 9 is used to adjust the film boundary displacement to achieve the purpose of adjusting the pretension of the film, thereby...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com