Multi-parameter ultrasonic wave fluid tester and use method thereof

An ultrasonic and tester technology, applied in the field of multi-parameter ultrasonic fluid testers, can solve the problems of inability to realize various data storage and linkage analysis, and achieve the effect of shortening positioning time, simple construction, and easy expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

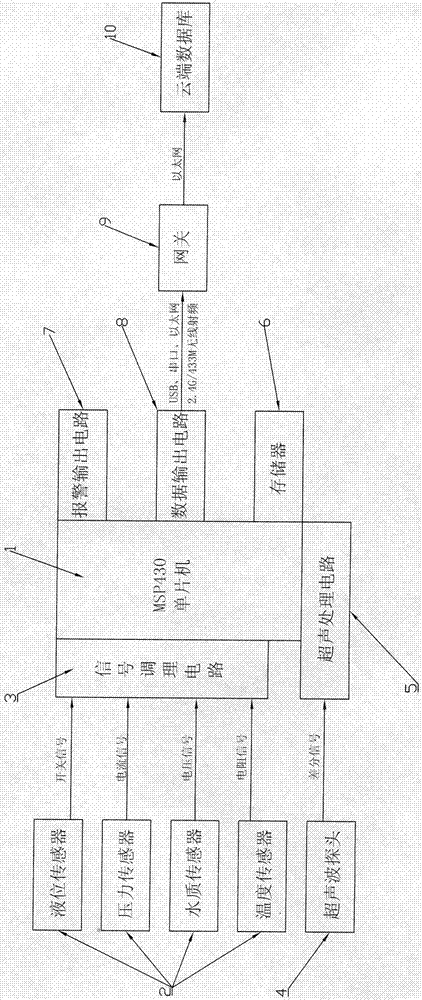

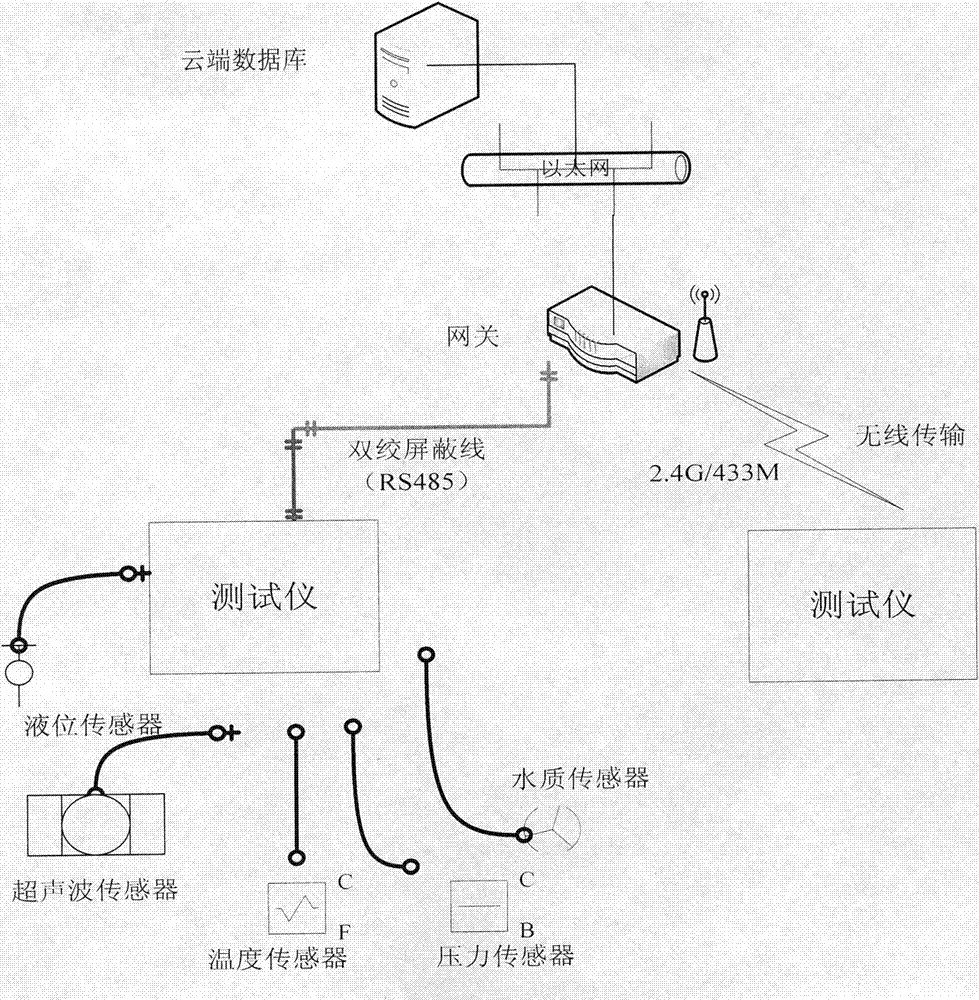

[0028] As shown in the figure, a multi-parameter ultrasonic fluid tester according to the present invention includes: MSP430 single-chip microcomputer 1, terminal sensor 2, signal conditioning circuit 3, ultrasonic probe 4, ultrasonic processing circuit 5, memory 6, alarm output circuit 7, Data output circuit 8, gateway 9, cloud database 10; terminal sensor 2 connects sensing information to signal conditioning circuit 3 through interface cable, ultrasonic probe 4 connects differential signal to ultrasonic processing circuit 5 through interface cable, signal conditioning circuit 3 , ultrasonic processing circuit 5, memory 6, alarm output circuit 7, and data output circuit 8 are respectively connected to MSP430 microcontroller 1, and data output circuit 8 is connected to gateway 9 in a wired / wireless manner, and gateway 9 is connected to cloud database 10 through Ethernet.

[0029] A method for using a multi-parameter ultrasonic fluid tester, comprising the following steps:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com