Device for measuring internal pressure of vacuum insulating panel and testing method thereof

A technology of vacuum insulation panels and measuring devices, which is applied in the direction of measuring devices, vacuum gauges, and measuring fluid pressure, etc., can solve the problems of difficult vacuum chamber volume, inability to measure vacuum insulation panels, and easy measurement errors, etc., and achieve high measurement accuracy, Measure the effect easily and quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

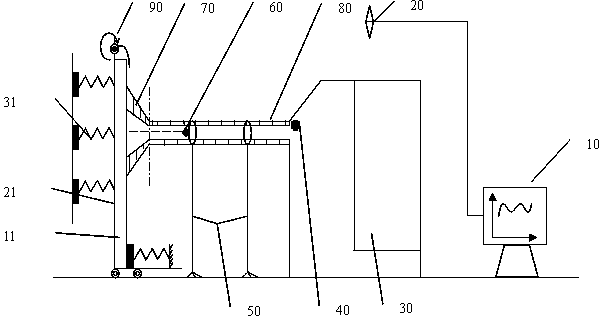

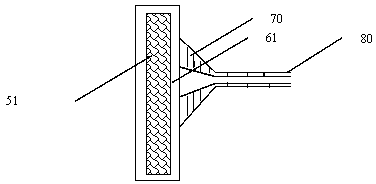

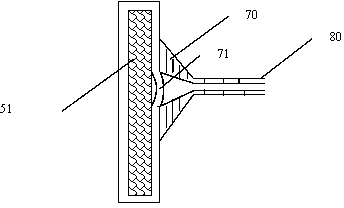

[0023] Such as figure 1 As shown, a device for measuring the internal pressure of a vacuum insulation panel is based on the fact that when there is a pressure difference between the inside and outside of the barrier membrane of the vacuum insulation panel, the membrane will bulge toward the side with the lower pressure, and the barrier membrane will reach equilibrium when the pressure is equal Principle, characterized in that 10. computer; 20. radio receiving device; 30. combined pump; 40. high-precision vacuum pressure sensor; 50. horizontal calibration frame; 60. miniature laser range finder; 80. Hard conduit; 90. Clip; 11. Vacuum insulation panel to be tested; 21. "L" shaped spring baffle; 31. Spring; 41. Cuboid spring baffle; 51. Core material of vacuum insulation panel; 61. Measurement The barrier film of the front vacuum insulation panel; 71. The deformed vacuum insulation panel barrier film.

[0024] It is characterized in that the vacuum insulation panel to be measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com