Optical module and scanning type image display device

A technology of optical modules and optical components, applied in optics, optical components, installation, etc., can solve the problems of optical axis offset, no hints, etc., to increase the area, prevent peeling, and reduce the deviation of the relative position of the light spot Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

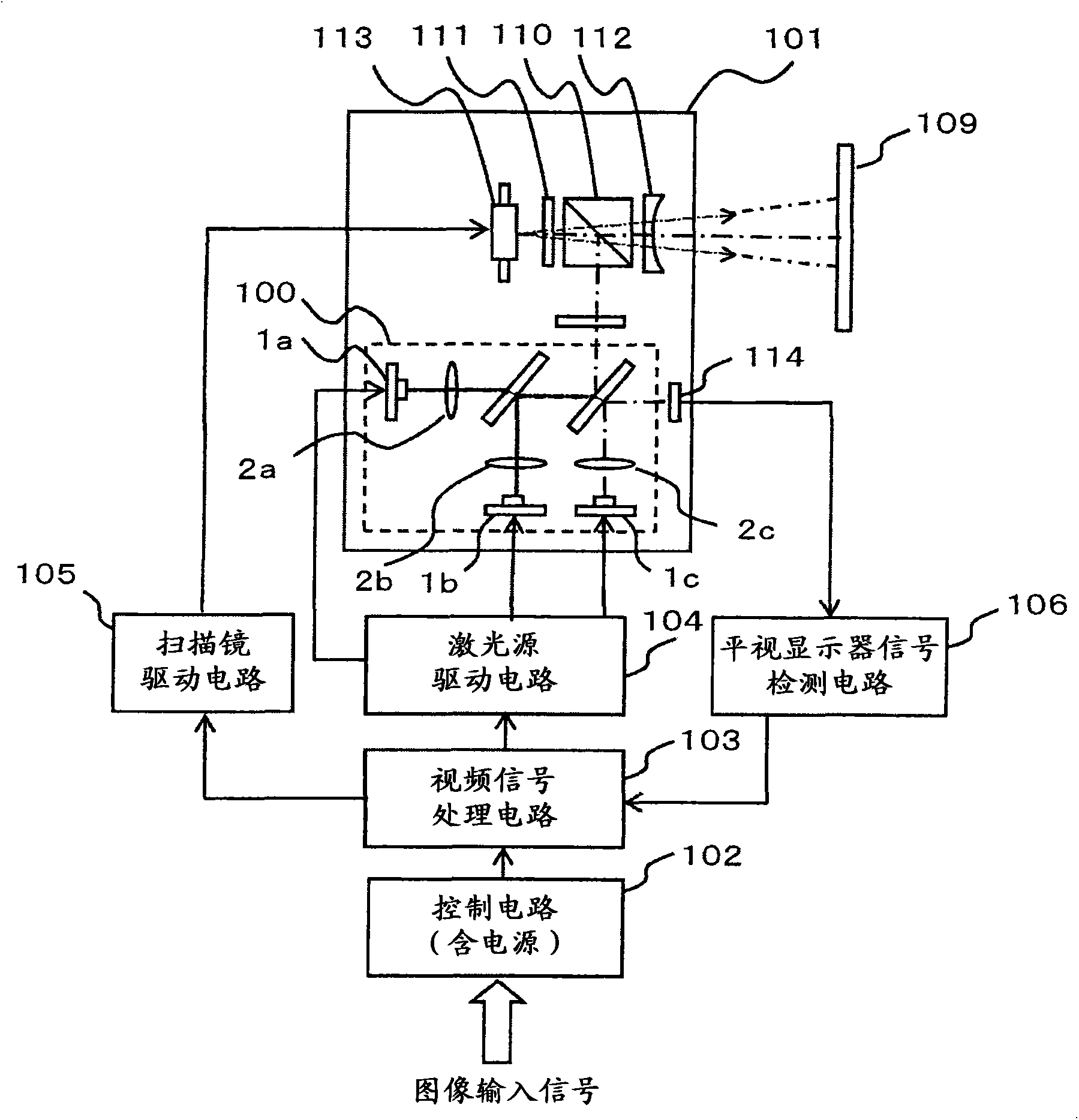

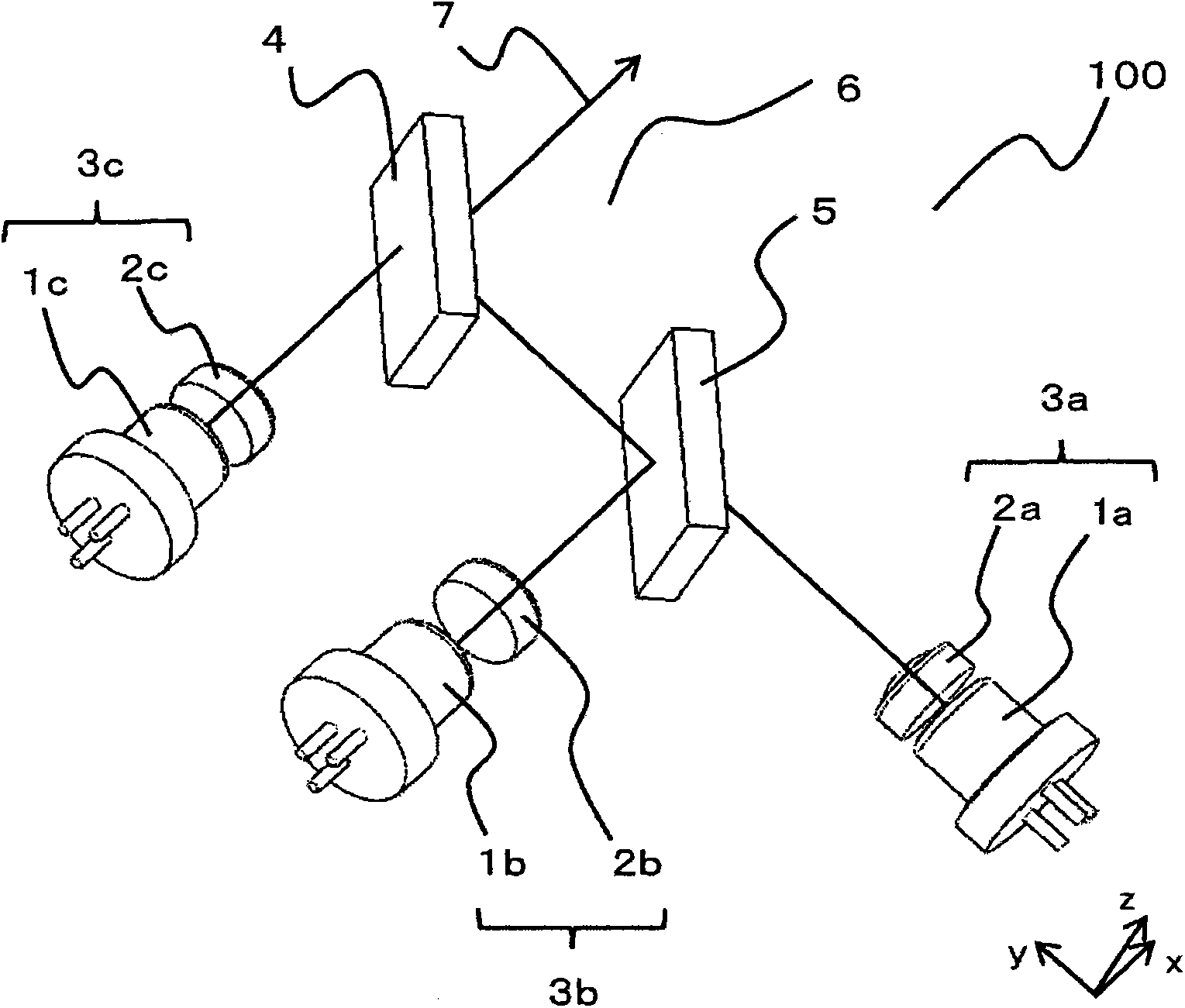

[0049] figure 1 It is a configuration diagram of a scanning image display device according to an embodiment of the present invention.

[0050] exist figure 1 Among them, the optical module 101 has: a laser source module 100, which has: a first laser 1a, a second laser 1b, The third laser 1c; and the beam coupling part, which makes the beams emitted from each laser source and passed through the first lens 2a, the second lens 2b, and the third lens 2c of the so-called collimating lens be optically coupled; A projection unit that projects the beam light onto the screen 109 ; and a scanning unit that two-dimensionally scans the projected beam light on the screen 109 . The projection unit includes a polarizing beam splitter (PBS) 110 , a 1 / 4 wave plate 111 , an angle of view enlarging element 112 , and the like. In addition, the scanning unit includes a scanning mirror 113 and the like.

[0051] An image input signal to be displayed is input to a video signal processing circuit...

Embodiment 2

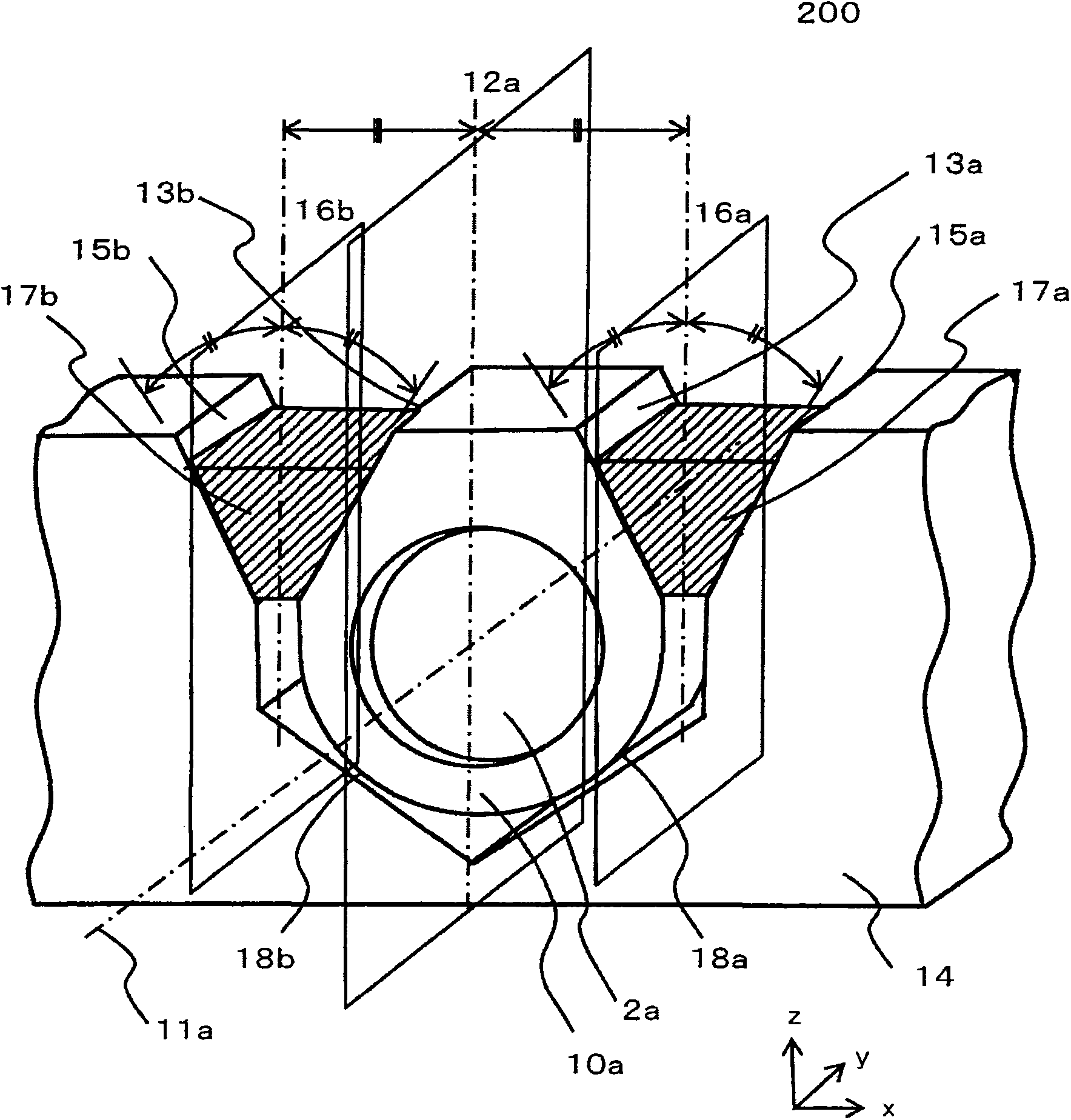

[0082] Figure 6 It is a sectional view showing the second embodiment of the mounting structure of the optical components of the optical module of the present invention.

[0083] use image 3 , Figure 4 When the mounting configuration 200 of the optical component is shown, displacement and rotation of the optical component are suppressed. When there is an adhesive between the slope 13a of the optical component holder 10a and the slope 15a of the housing 14, the adhesive may drip from the narrow portion 400a between the slope 13a and the slope 15a. For dripping adhesive, by using Figure 6 The mounting structure 201 of optical components as shown can suppress displacement and rotation of the lens 2a.

[0084] In the optical component mounting structure 201, the first lens 402a is held by the optical component holder 410a for holding the first lens 402a.

[0085] On the optical component holder 410a, an inclined surface 413a and an inclined surface 413b are provided symmet...

Embodiment 3

[0095] Figure 7 It is a cross-sectional view showing a third embodiment of the mounting structure of the optical components of the optical module of the present invention.

[0096] The difference from Embodiment 1 and Embodiment 2 is that the slope 13a and the slope 13b of the optical component holder 10a adopt the curved surface 501a and the curved surface 501b, and the slope 15a and the slope 15b of the housing 14 adopt the curved surface 502a and the curved surface 502b. The curvatures of the curved surface 501 a , the curved surface 501 b , the curved surface 502 a , and the curved surface 502 b are the same, and the central axes of the curved surfaces are parallel to the optical axis 11 a of the lens 2 . The curved surface 501a of the optical component holder 10a and the curved surface 502a of the housing 14 are symmetrical with respect to the second symmetrical plane 16a passing through the center of the gap between the curved surface 501a and the curved surface 502a an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com