High-power track welding efficient excitation single-phase generator

A single-phase generator and orbital welding technology, which is applied in the direction of synchronous generators, can solve problems such as low reliability, three-phase imbalance, and large equipment volume, so as to reduce investment and use costs, improve current impact capability, and improve Effect of Transient Response Capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

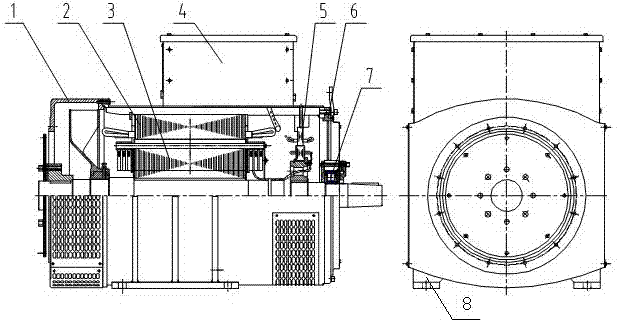

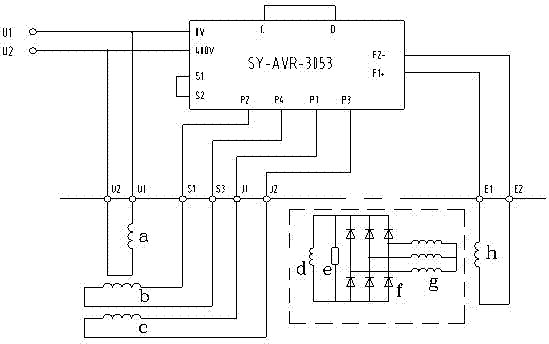

[0013] Such as figure 1 As shown, the present invention works and implements like this, it comprises front end cover 1, stator 2, rotor 3, excitation box 4, exciter 5, rear end cover 6, bearing 7 and support frame 8, it is characterized in that: front end The cover 1 is connected with the stator 2, the stator 2 is used to fix the stator core, the stator 2 is connected with the rotor 3 through the bearing 7 of the rear end cover 6, the rotor 3 runs in the inner cavity of the stator 2, and the exciter 5 is in a position between the stator 2 and the rotor 3 side, to provide excitation energy for the rotor field winding, the frequency is 50HZ, the rated power is 400kW, the rated voltage is 400V, the rated power factor is 0.8, the stator slot is 60 slots, the excitation box 4 is installed on the upper end of the generator, and the whole generator uses two Support frame 8 supports. The stator core in the stator 2 is embedded with a high-power single-phase winding, a third harmonic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com