Differential wet electric precipitator

A wet electrostatic precipitator, differential technology, applied in the direction of external electrostatic separator, electrode structure, electrostatic separation, etc., can solve the problems of late start, low utilization rate of flat electric field space, inability to effectively play the advantages of wet electrostatic precipitator, etc., to achieve The dust collection area is large, the electric field space utilization rate is high, and the effect of improving the dust collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

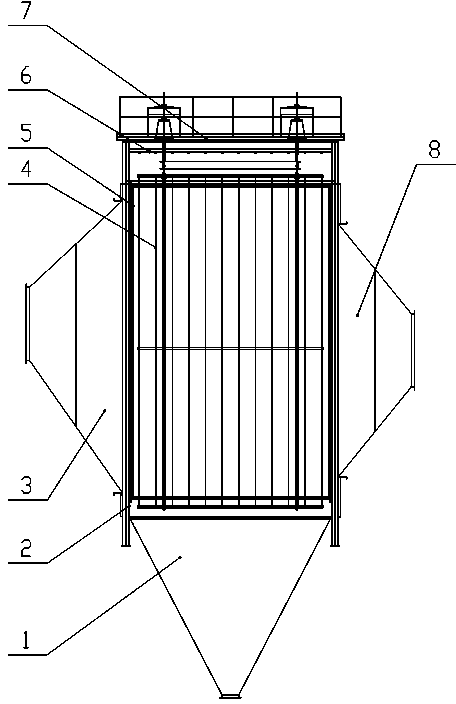

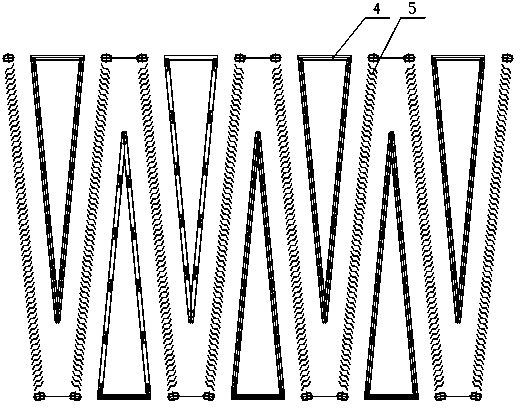

[0022] like figure 1 As shown, the ash hopper 1 is arranged at the lower part of the casing 2, the inlet head 3 and the outlet head 8 are arranged on both sides of the casing 2, and the top cover 7 is arranged on the top of the casing 2, thereby forming a sealed chamber. The cathode frame 4 and the differential plate row 5 are arranged in a staggered manner inside the housing 2 , and the cathode shower system 6 is arranged on the upper part of the cathode frame 4 with a certain distance from the cathode frame 4 .

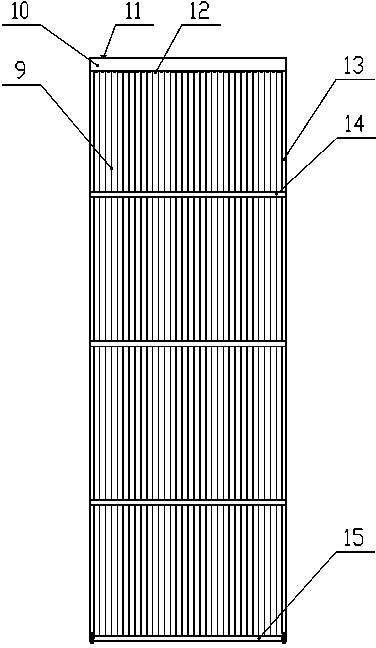

[0023] like figure 2 As shown, the differential plate row 5 is composed of a number of differential plates 9 arranged equidistantly. The upper part of the hanging beam 10 is correspondingly provided with a water inlet 11, and the lower part is provided with a first nozzle 12. The first nozzle 12 is arranged in the center between the differential plates 9. The first nozzle 12 adopts a two-way pointing type, which can be directed to the two sides respectively. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com