Roller way balance

A technology of roller table scale and scale body, which is applied in length measuring device, metal processing equipment, metal rolling, etc., can solve the problems of poor long-term stability, inability to operate at close range on site, and large repeatability error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below in conjunction with accompanying drawing and specific examples the present invention will be further described:

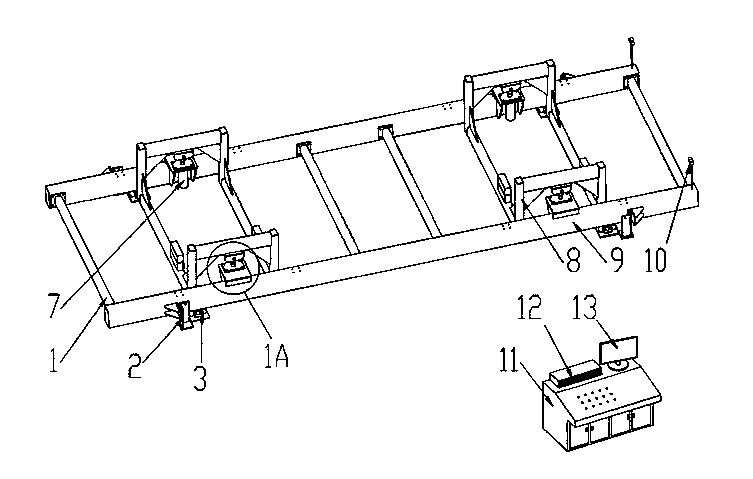

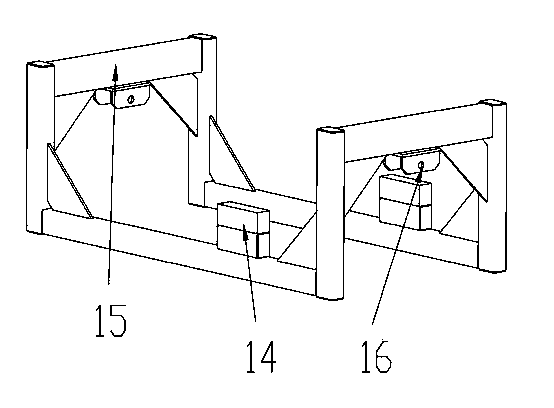

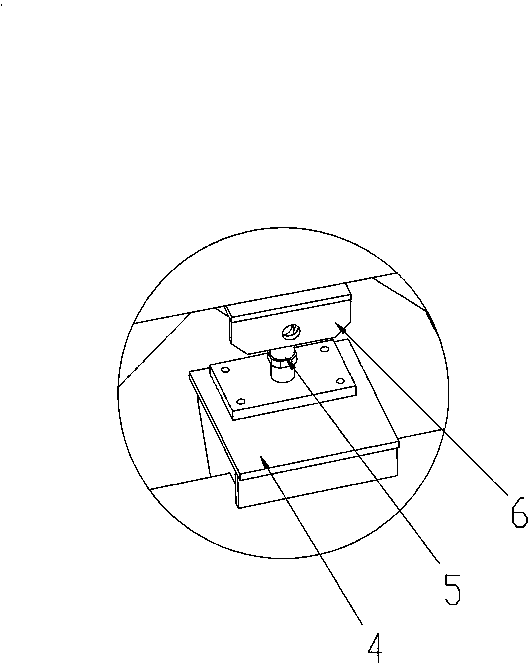

[0009] The installation of the present invention is installed on the hot rolling production line of the iron and steel plant and under the condition of non-stop production. During installation, the scale body beam 1 is inserted from one side between the two supporting rollers on the hot rolling line, and after the 8 beams are placed evenly, Longitudinal girder 9 is fixed as one with each crossbeam 1 with bolt respectively from both sides, and scale body is installed like this. Similarly, when installing the lifting and weighing frame 8, after inserting the crossbeam from one end, assemble the double frame type gantry frame 15, the cylinder body of the hydraulic unit 7 is fixed on the hydraulic base 4, and the head is connected with the universal joint 5, and then through the pin 16 is integrated with the upper fixing plate 6, which can ensure that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com