Diesel engine exhaust gas purifier diagnosing method based on sound wave signal HHT marginal spectrum

A technology of sound wave signal and diagnosis method, which is applied in the diagnosis device of exhaust treatment device, exhaust treatment, machine/engine, etc., and can solve the difficult problems of finding and treating tiny cracks in exhaust purifiers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

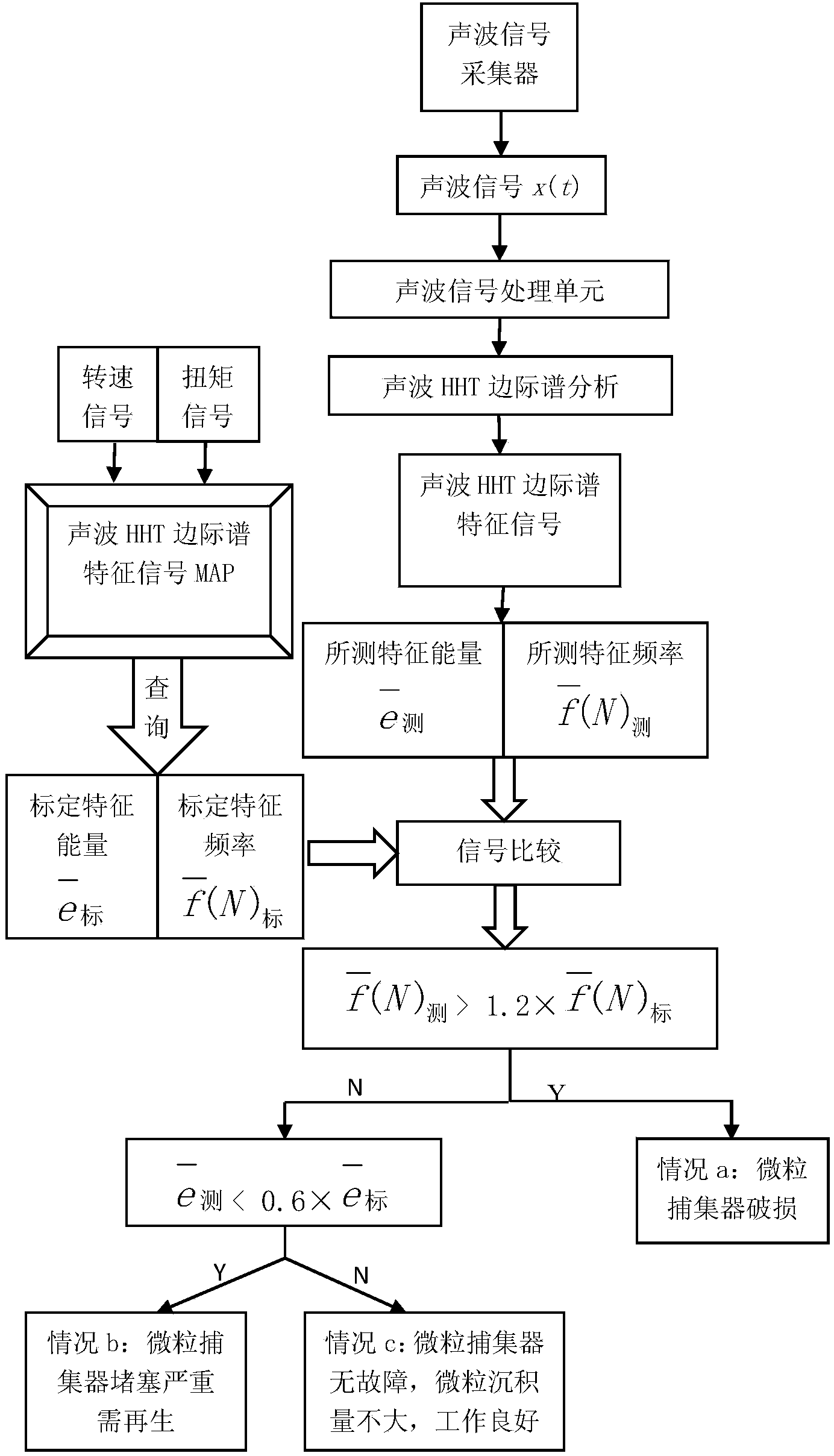

[0029] A method for diagnosing a diesel engine exhaust purifier based on an acoustic wave signal HHT marginal spectrum, the method comprising:

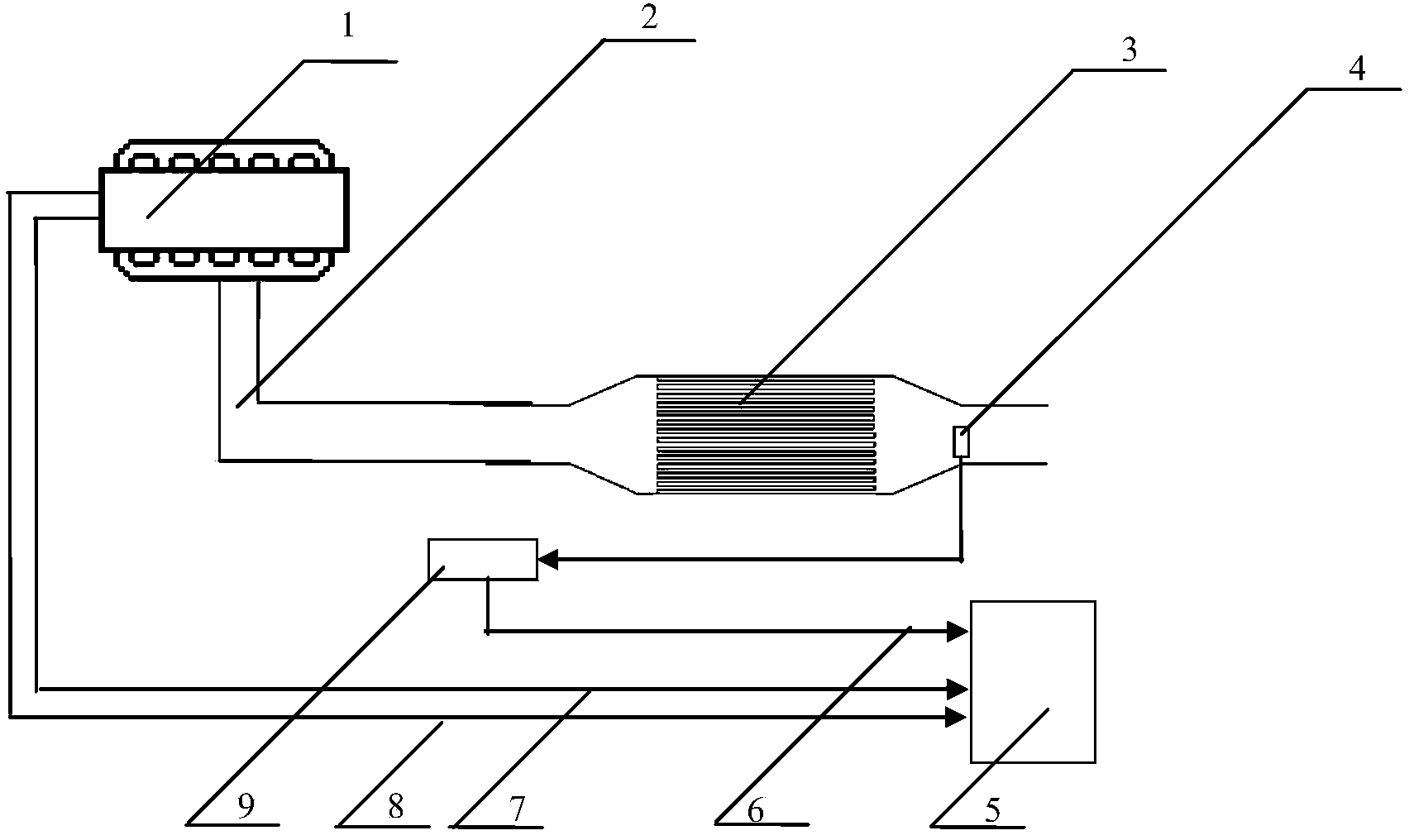

[0030] Step 1 Arrange the acoustic wave signal collector 4 at the outlet of the diesel engine exhaust purifier 3, the output end of the acoustic wave signal collector 4 is connected to the input end of the acoustic wave signal processing unit 9, and the output end of the acoustic wave signal processing unit 9 is connected to the electric The input terminal of the control unit 5 is connected.

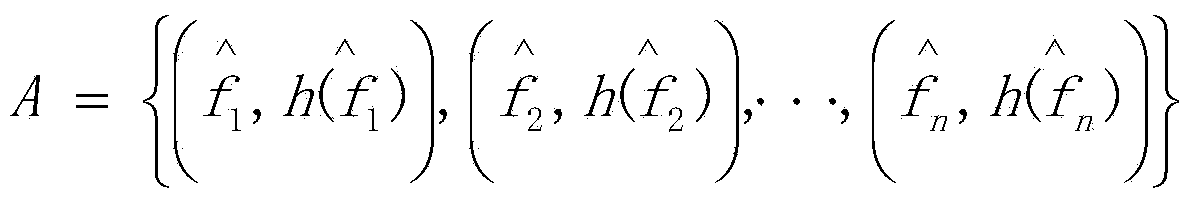

[0031] Step 2: During the working process of the diesel engine, the acoustic signal collector 4 collects the acoustic signal x(t) generated by the exhaust purifier 3, and the acoustic signal processing unit 9 performs acoustic HHT marginal spectrum analysis on the acoustic signal x(t), and calculates the marginal spectrum h(f); perform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com