A heat dissipation control method for a loader engine

A control method and engine technology, which is applied in the direction of machine/engine, engine components, engine cooling, etc., can solve the problems of large changes in fan speed, affecting the service life of shafts, and large range of speed changes, so as to achieve good energy-saving effect and prolong The effect of service life and stable fan speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

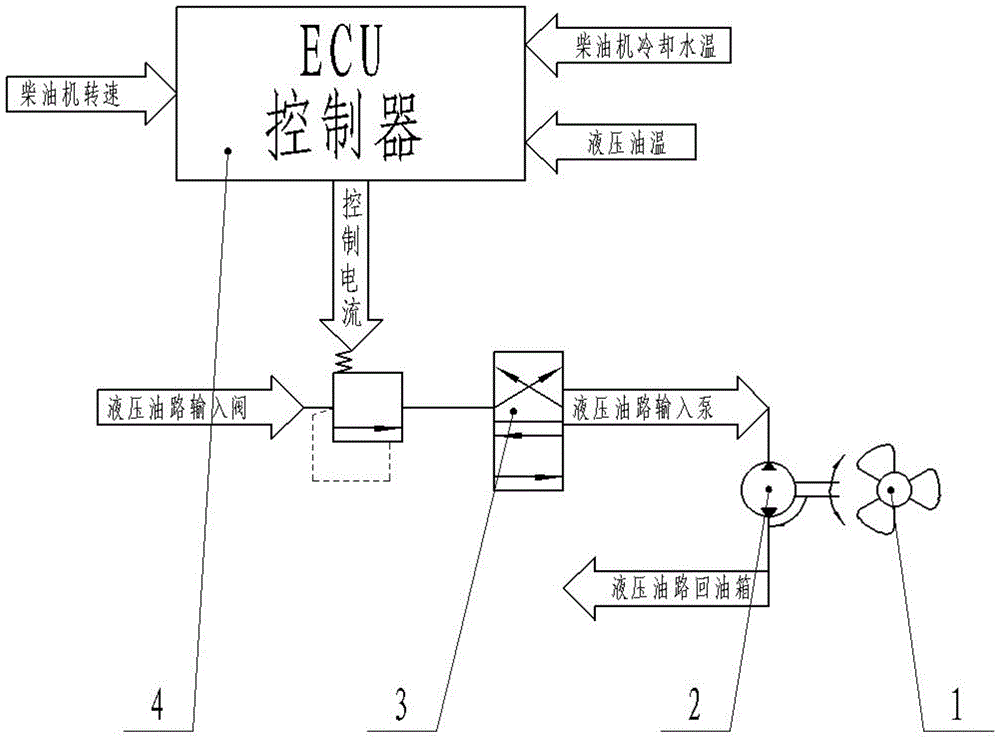

[0025] Such as figure 1 As shown, the present invention includes a fan 1 and a hydraulic motor 2 for driving the fan 1, the hydraulic motor 2 is connected with the electric proportional pressure reducing valve 3, the electric proportional pressure reducing valve 3 is connected with the ECU controller 4, and the ECU controller 4 is provided with a receiver The engine speed signal unit, the unit is connected with the engine speed measuring instrument, the engine speed change rate δ every 30ms≤45rpm, the ECU controller 4 takes water temperature and oil temperature as control parameters, slowly adjusts the current of the electric proportional pressure reducing valve 3, and controls the drive The hydraulic motor 2 of the fan 1 makes the whole machine work in the optimum temperature range.

[0026] In this embodiment, because the engine speed change rate δ is less than or equal to 45 rpm per 30 ms, the ECU controller 4 uses water temperature and oil temperature as control parameters...

Embodiment 2

[0028] The difference from Embodiment 1 is that the ECU controller 4 only takes the engine speed as the control parameter to control the speed of the fan when the engine speed change rate δ is greater than 45rpm every 30ms, adjusts the current of the electric proportional pressure reducing valve 3, and controls the driving fan The hydraulic motor 2 of 1 makes the fan 1 work stably within a certain speed range or makes the fan 1 speed change slowly.

[0029] In this embodiment, because the rate of change of the engine speed δ is greater than 45rpm every 30ms, the ECU controller 4 only uses the engine speed as a control parameter to adjust the current of the electric proportional pressure reducing valve 3 to control the hydraulic motor 2 driving the fan 1, so that the fan 1 The speed changes slowly to achieve the effect of energy saving and noise reduction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com