Carbon nanotube sensor and production method

A technology of carbon nanotubes and sensors, applied in the field of sensors, can solve the problems of complex quantitative relationship, inability to align, low measurement efficiency, etc., and achieve the effect of simple quantitative relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a carbon nanotube sensor to more accurately measure the change in the conductivity of the sensitive area, so that the carbon nanotube sensor can be used to achieve detection more accurately.

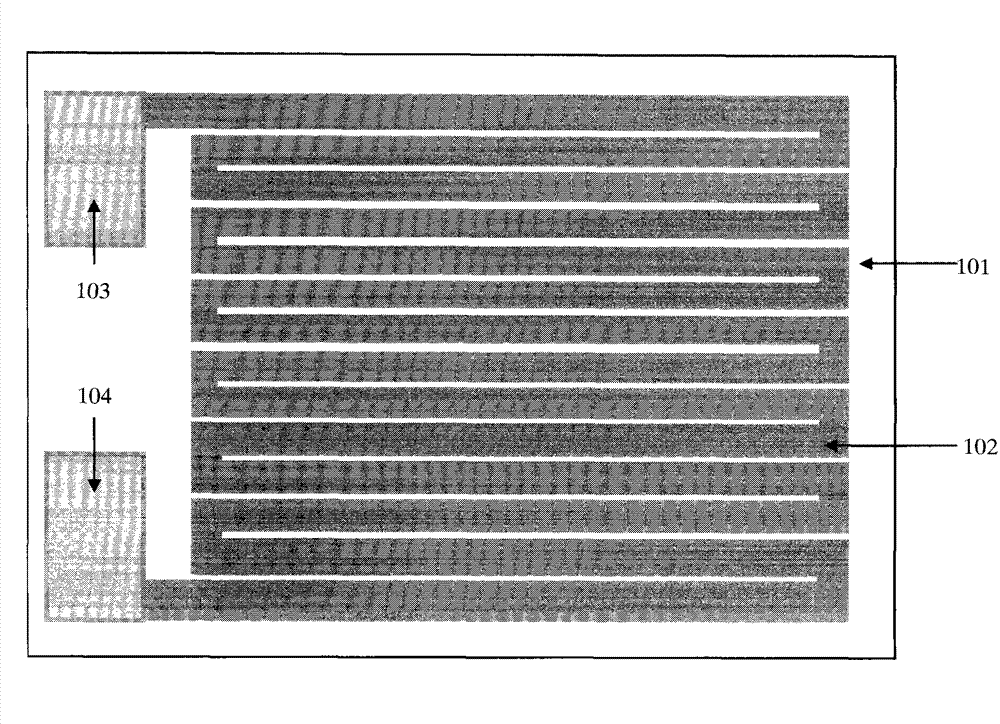

[0051] figure 1 A structural diagram of a carbon nanotube sensor according to Embodiment 1 of the present invention is shown. like figure 1 As shown, the carbon nanotube sensor includes: a substrate 101 and a sensing unit located on the substrate.

[0052] In this embodiment, the substrate 101 may be one of filter paper, printing paper, and polyethylene terephthalate, but the present invention is not limited thereto, but may be suitable for providing support for the sensing unit and not Any sheet material that conducts electricity, for example, the substrate can also be cloth, printed circuit board, ceramics, silicon wafer covered with silicon dioxide film, glass, etc.

[0053] The sensing unit includes a sensitive area 102 and a first electrode 103 and...

Embodiment 2

[0074]Described in Example 1 is the case where a sensing unit is formed on a substrate. In this case, a sensor can only use one probe substance to detect one target substance at a time, and cannot detect multiple target substances simultaneously. In order to further solve this problem, in this embodiment, two or more sensor units are formed on the substrate. The plurality of sensing units can be arranged in parallel to form an array. Each sensing unit may have the same structure as the sensing unit in Example 1, and the probe substances in the sensitive regions of different sensing units may be different.

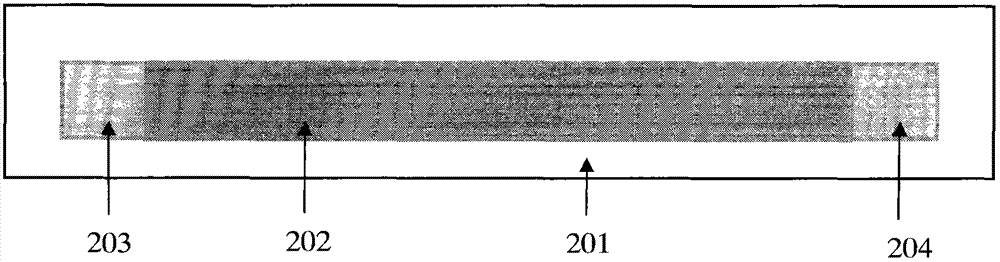

[0075] Figure 4 and Figure 5 A schematic diagram showing a carbon nanotube array with different patterns of sensitive region arrays formed on a substrate. exist Figure 4 and Figure 5 Among them, each sensitive area 402, 502 of the sensitive area array contains different probe substances and carbon nanotubes. in formation Figure 4 and Figure 5 When the array o...

Embodiment 3

[0079] This embodiment provides another carbon nanotube sensor to more accurately measure the change in the conductivity of the sensitive area, so that the carbon nanotube sensor can be used to achieve detection more accurately.

[0080] The carbon nanotube sensor in this embodiment has the same figure 1 similar structure, so will still refer to figure 1 to describe. like figure 1 As shown, the carbon nanotube sensor includes: a substrate 101 and a sensing unit located on the substrate.

[0081] The sensing unit includes a sensitive area 102 and a first electrode 103 and a second electrode 104 connected to two ends of the sensitive area. The sensitive zone consists of carbon nanotubes mixed with probe species.

[0082] In this embodiment, in order to solve the complex series-parallel mixing relationship between the micro-regions with changed conductance and the regions with no change in conductance due to the large-area continuous distribution of carbon nanotubes in the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com