On-line power plant SCR (Selective Catalytic Reduction) denitration system catalyst activity monitoring method

A technology of catalysts and fresh catalysts, which is applied in the direction of using catalysis for chemical analysis, etc., which can solve the problems of unfavorable denitration system efficient operation, inconvenient visual judgment of catalysts, long time intervals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

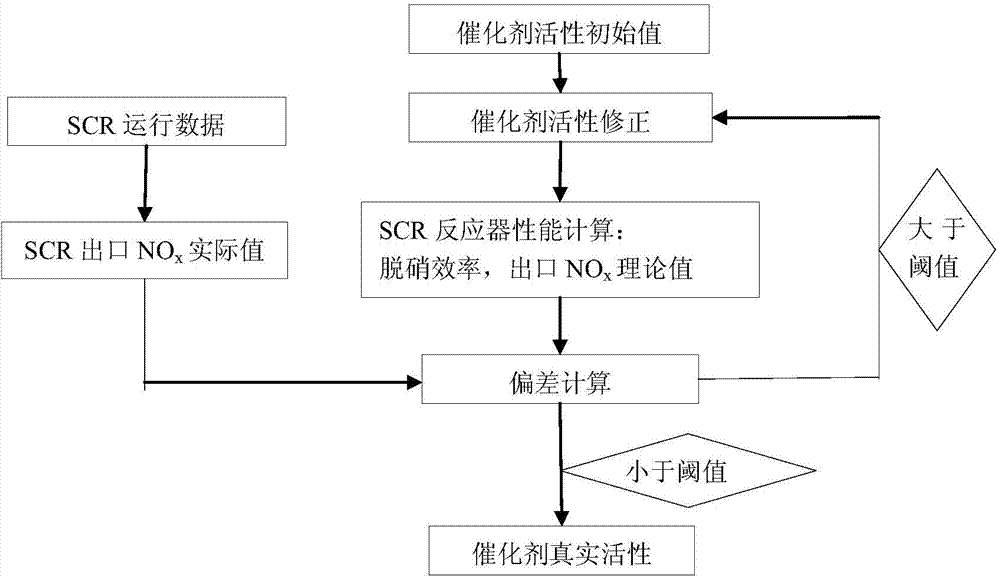

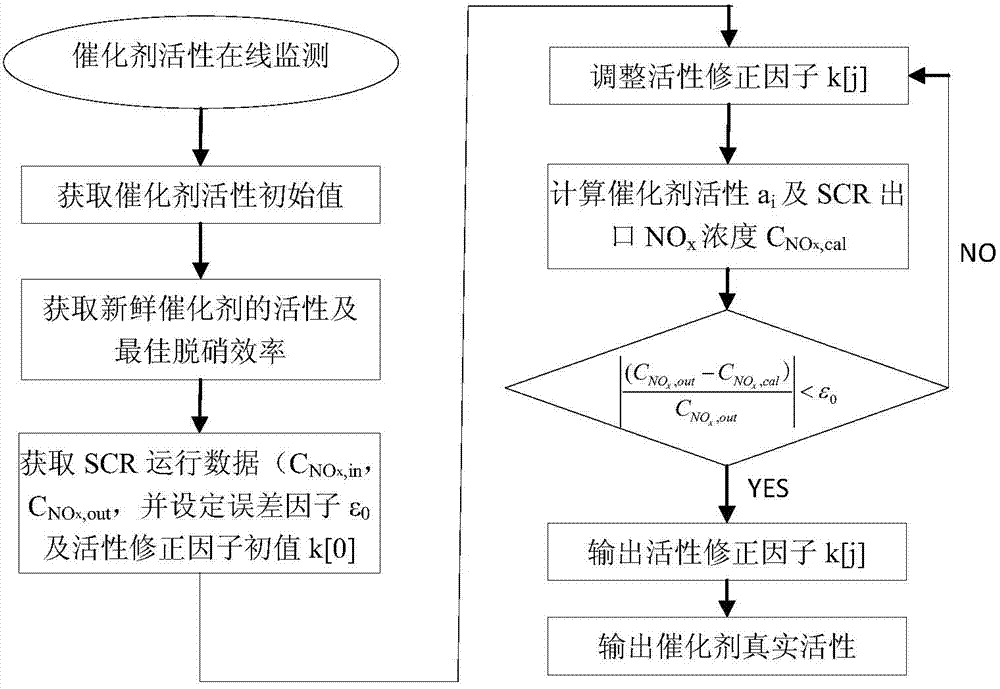

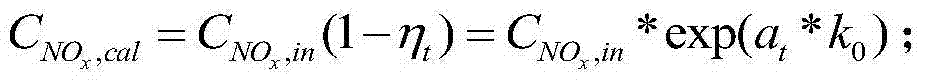

[0038] The present invention provides a method for on-line monitoring of catalyst activity in an SCR denitrification system of a power plant. The present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

[0039] Taking a 600MW unit in a certain power plant as the research object, the specific implementation of the present invention is described in detail.

[0040] (1) The SCR denitrification system of this unit is arranged before the air preheater after the economizer, and belongs to the plate catalyst structure type. The SCR denitrification system has two reactors, A and B, arranged symmetrically. The structural parameters of the catalyst in the SCR denitrification system are shown in Table 1.

[0041] Table 1 Structural parameters of catalysts in SCR denitrification system

[0042]

[0043]

[0044] (2) Design parameters of SCR denitrification system:

[0045] (A) The boiler uses the designe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com