Roller electrode bending device

A bending device and roller-type technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve problems such as unfavorable mass production, scratches on the electrode surface, and low bending efficiency, so as to reduce scratches and scratches. damage, ensure bending quality, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention discloses a device capable of bending all electrodes on an IGBT module at one time by means of rolling.

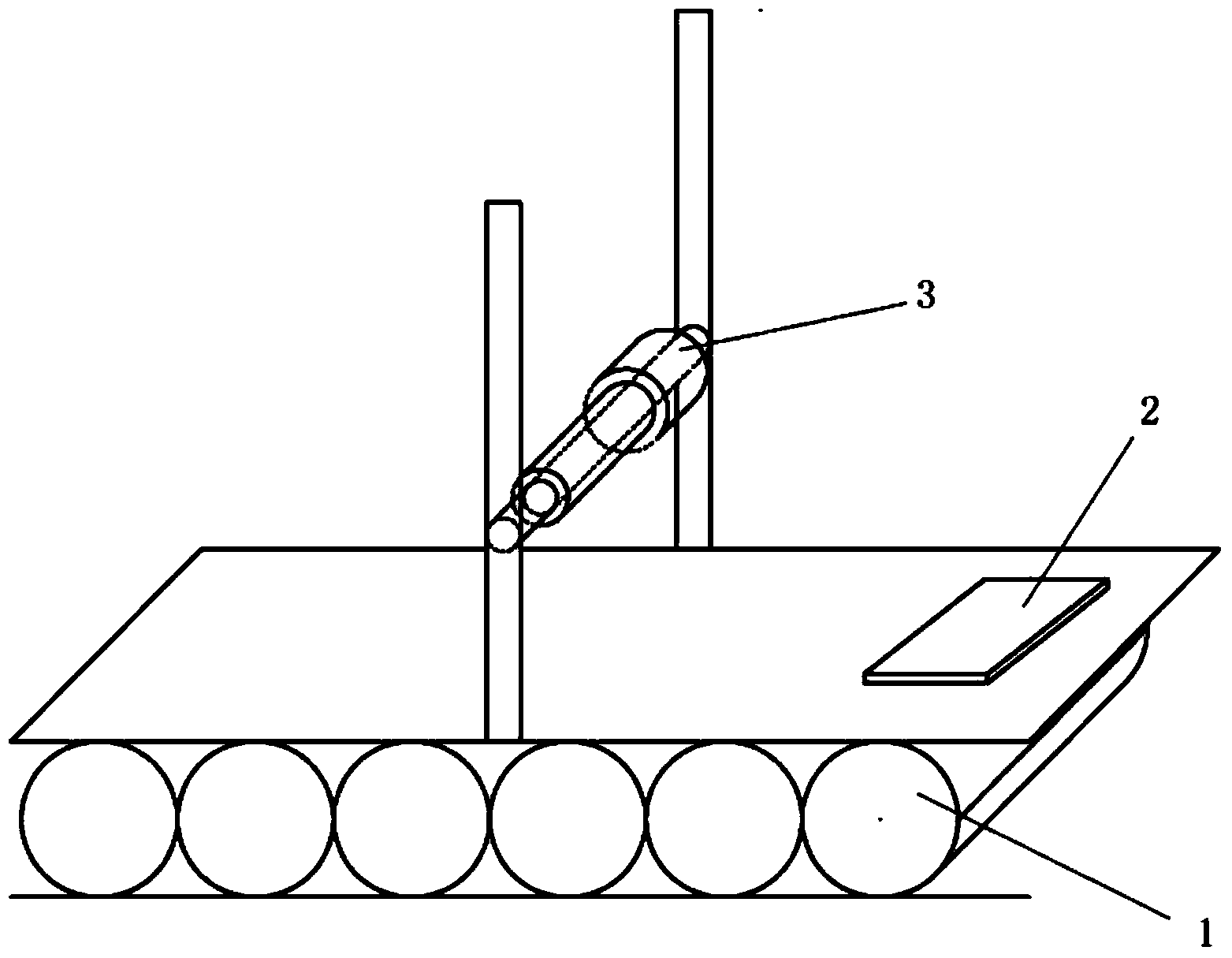

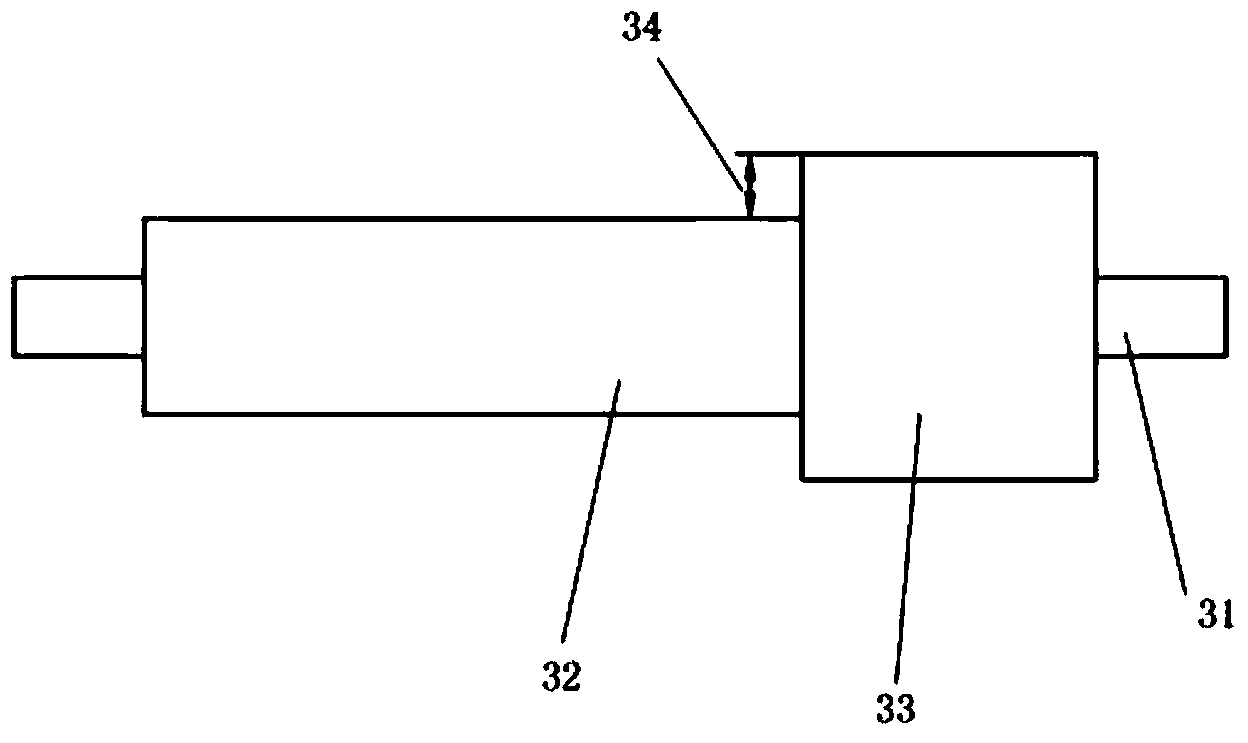

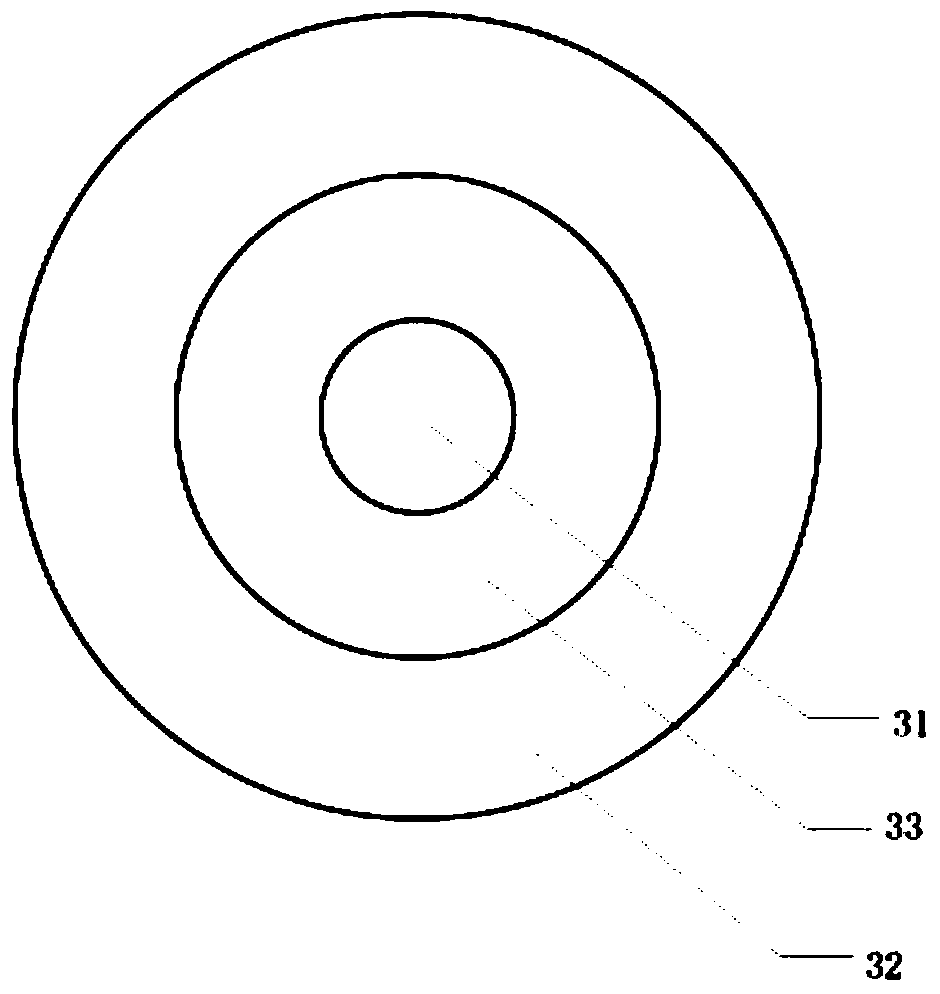

[0030] Such as figure 1 or Figure 4 As shown, in the embodiment of the present invention, a driving device is used to drive the carrying plate to move relative to the rolling part in the horizontal direction. In the embodiment of the present invention, an electric roller 1 and a rolling part 3 are added on the basis of the original carrying plate 2 . The carrier plate 2 is used for fixing the IGBT module 4 . The electric roller 1 is driven by a driving device, and is used to drive the carrying plate 2 to move in the horizontal direction. The rolling part 3 further includes a connecting shaft 31 and several rollers 32 or 33 . Both ends of the connecting shaft 31 are connected to fixed parts on the device, and the height of the connecting shaft 31 can be adjusted according to the height of the IGBT module 4 . The first roller 32 and the second roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com