Single coiled core, lithium battery with single coiled core and continuous coiling method for single coiled core

A technology for single winding core and lithium battery, which is applied in the field of single winding core, lithium battery with single winding core and continuous winding of single winding core, which can solve the problems of complicated procedures, inability to produce high rate discharge, and inflation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

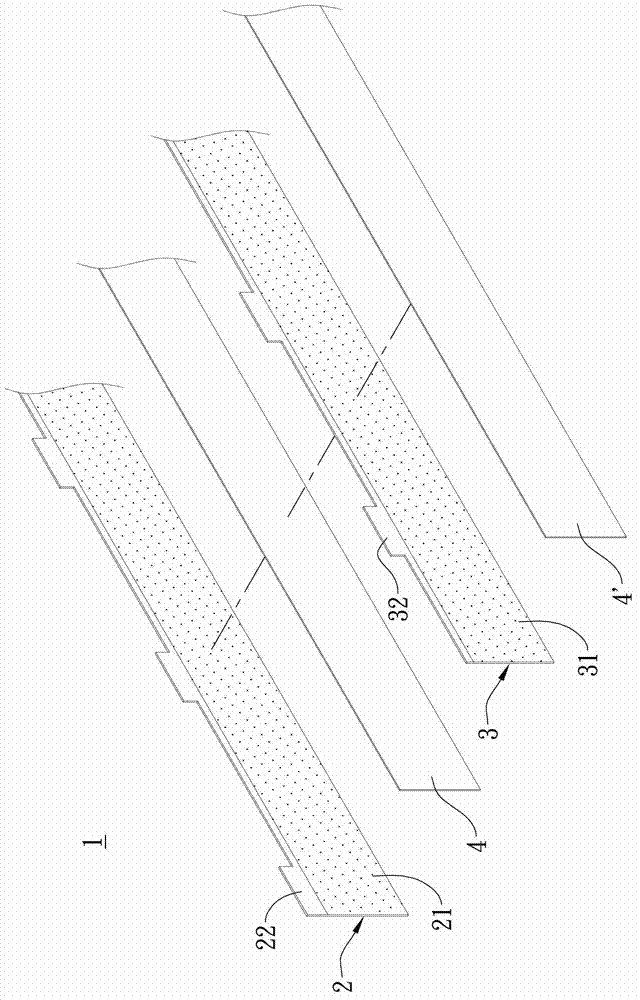

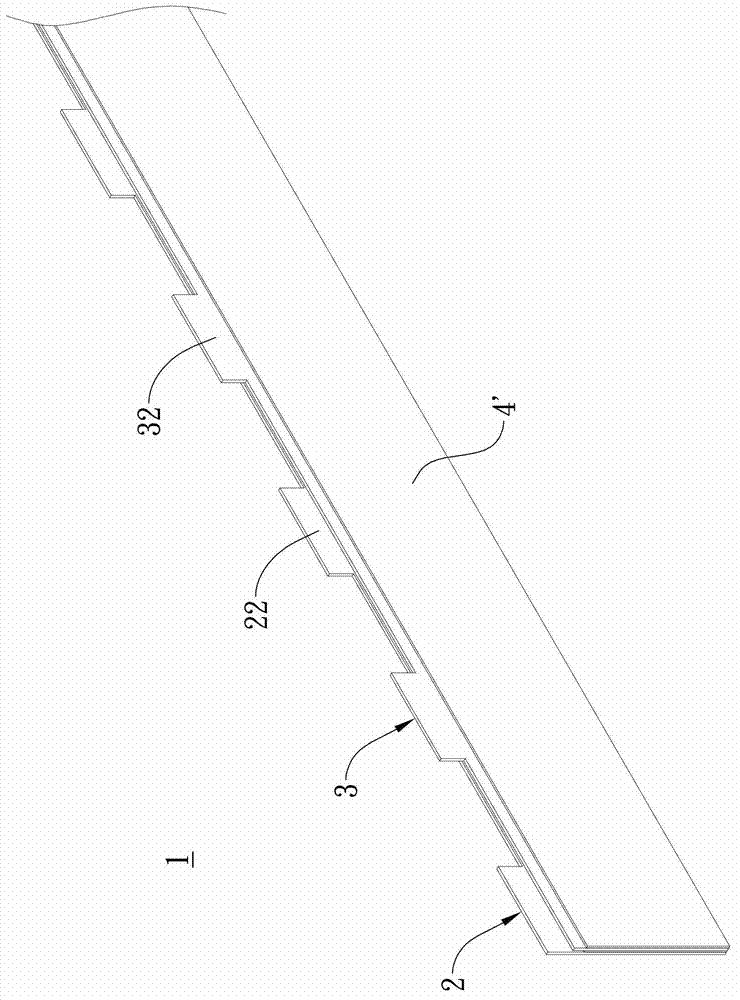

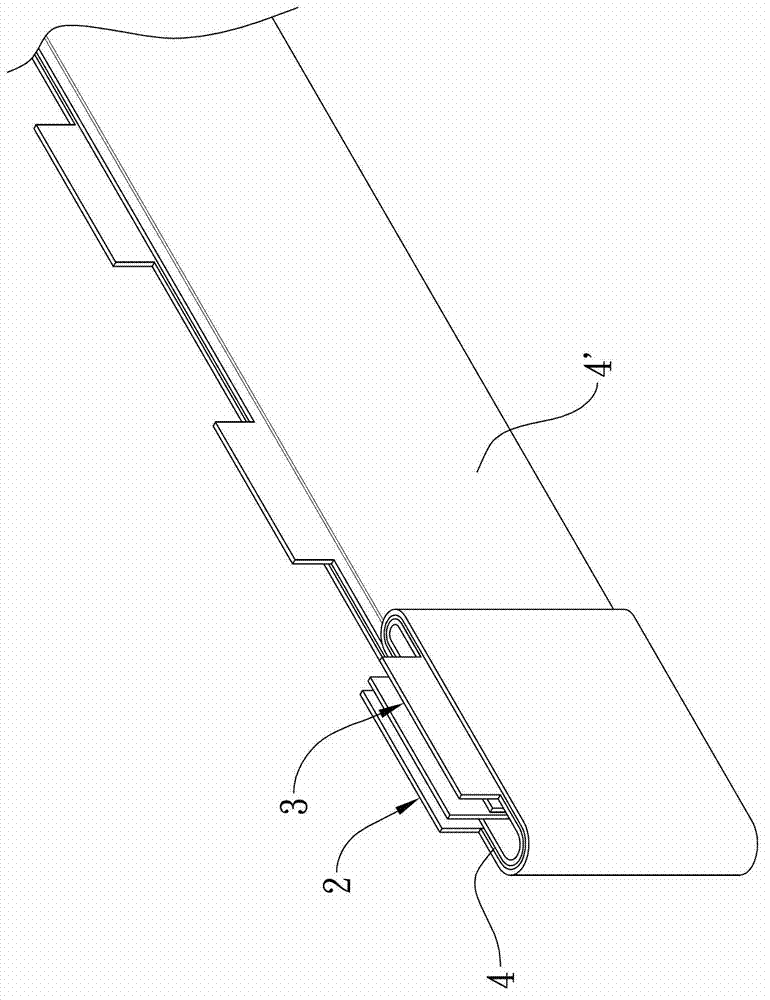

[0031] see figure 1 , 2 As shown, it is a preferred embodiment of the single winding core 1 of the present invention, including a strip-shaped positive electrode sheet 2, a strip-shaped negative electrode sheet 3, a first separator 4 and a second separator 4'.

[0032] The positive electrode sheet 2 is preferably made of aluminum metal, and most of the lower end regions of the positive and negative surfaces of the positive electrode sheet 2 form the positive electrode region 21. The positive electrode region 21 is the surface of the positive electrode sheet 2 coated with a layer of mixed positive electrode material, conductive The positive electrode slurry of the agent, the binder and the solvent is formed after the positive electrode slurry is dried and rolled. One side of the positive electrode sheet 2 in the longitudinal direction, that is, the upper end region of the positive electrode sheet 2 is provided with a plurality of equally spaced positive electrode tabs 22 exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com