Axial diode photovoltaic junction box

A technology of axial diodes and junction boxes, applied in the direction of photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve the problems of high heat generation of bypass diodes, poor heat dissipation capacity of junction boxes, and reduced operational reliability, so as to save welding process, convenient manufacturing, and the effect of reducing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

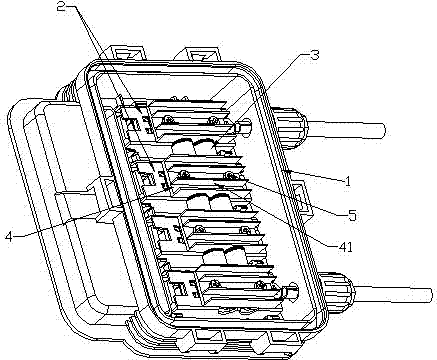

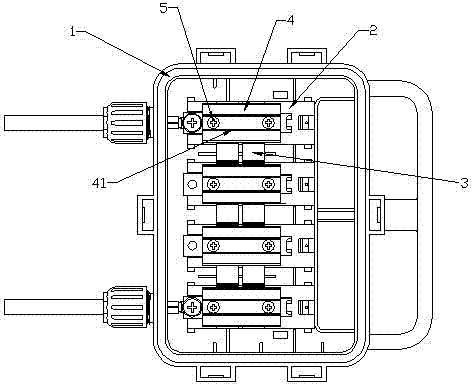

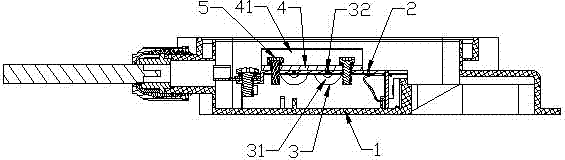

[0011] As shown in the figure, the axial diode photovoltaic junction box includes a box body 1, the bottom of the box body is provided with multi-phase conductors 2 side by side, the ends of the conductors are provided with connection terminals, and bypass diodes are connected between the conductors of each phase. 3; The bypass diode 3 is an axial diode, which has a cylindrical tube body 31 and a pair of pins 32 located at both ends of the tube body and coaxial with the tube body; a pair of pins 32 of the bypass diode are respectively overlapped On the two conductors 2, a heat sink 4 is pressed on the pin 32, and the heat sink 4 and the conductor 2 are connected and fixed by screws 5. Heat dissipation fins 41 are provided on the top surface of the heat sink 4. The radiator 4 is made of aluminum alloy profiles with constant cross section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com