Single-power-source VPPA-GTAW binary electric-arc punching welding method

A technology of arc perforation and welding method, which is applied in the direction of arc welding equipment, welding equipment, plasma welding equipment, etc., to achieve the effect of increasing the penetration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

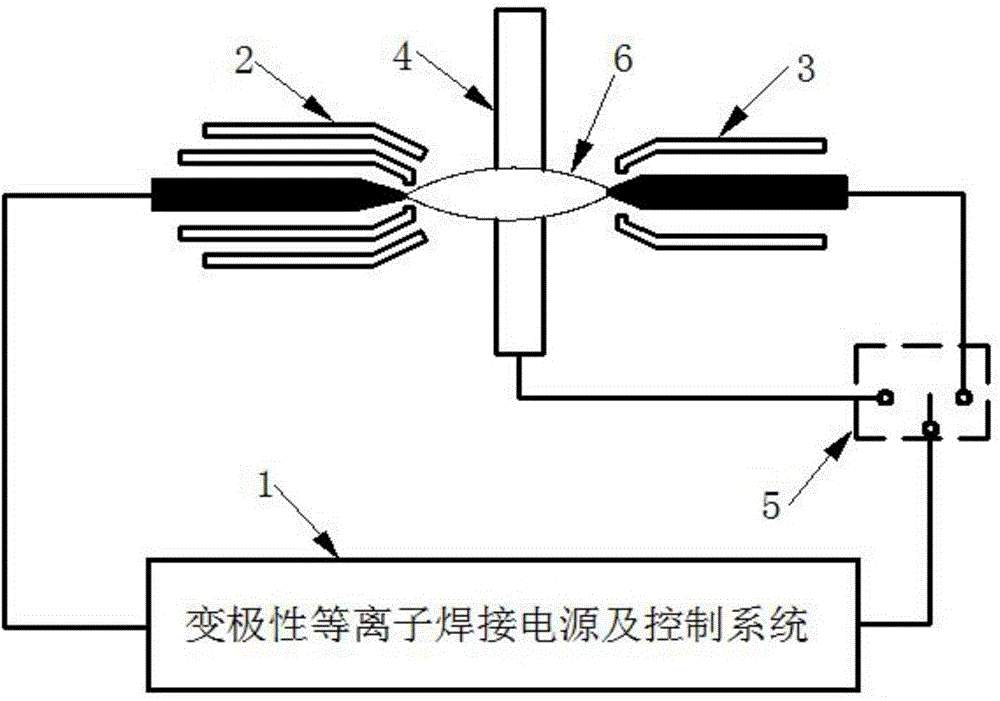

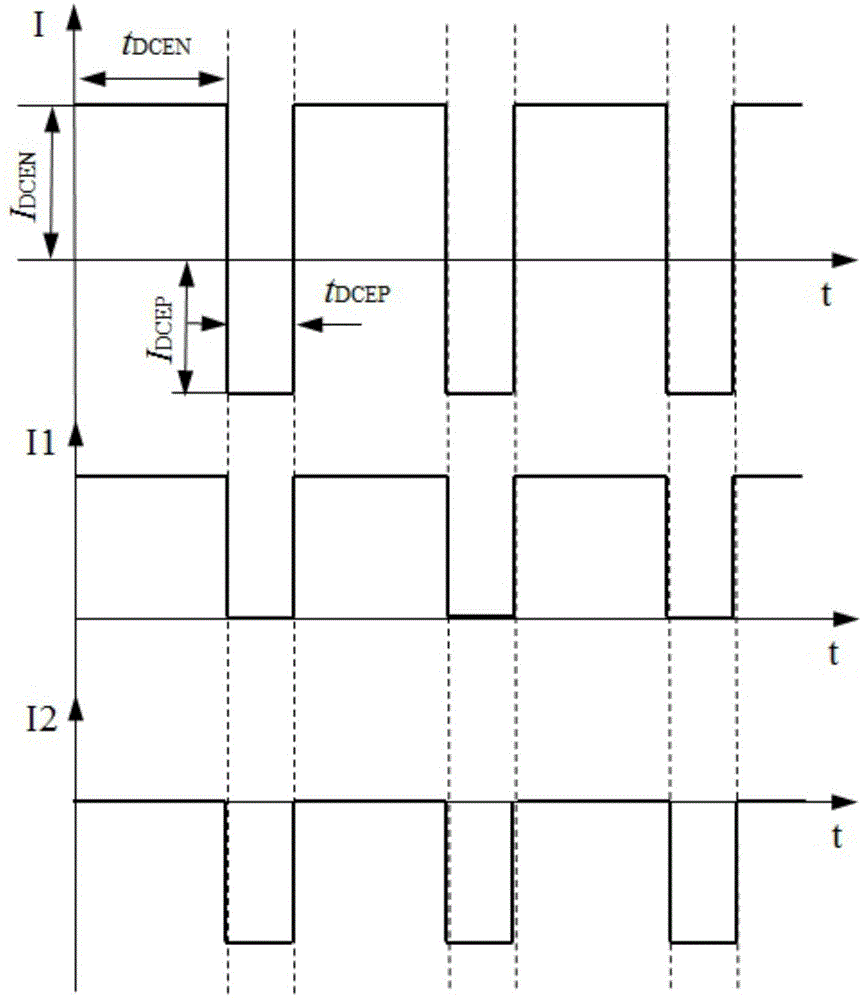

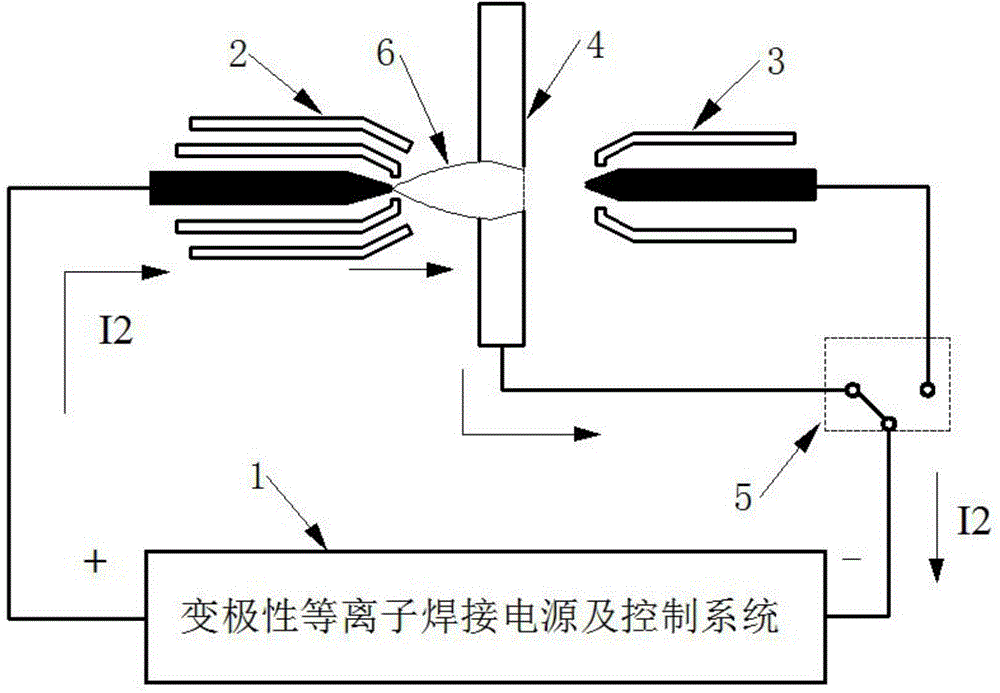

[0031] Such as figure 1 Shown is a schematic diagram of the working principle of dual-state arc perforation welding. The single-power VPPA-GTAW dual-state arc perforation welding device includes welding power supply and its control system 1, plasma welding torch 2, TIG welding torch 3, workpiece to be welded 4 and semiconductor commutation Switch 5; the plasma welding torch 2 and the TIG welding torch 3 are respectively placed at appropriate positions on both sides of the workpiece 4 to be welded. Adjust the parameters of the welding torch to meet the welding requirements; the connection method of the welding method related to the electrical circuit, the gas and water connections that the welding torch must use are conventional connections;

[0032] The whole welding system includes two independent current paths: welding power supply—TIG welding torch 3—plasma welding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com