Compression system for waste transfer station

A technology of garbage transfer station and compression system, applied in the field of garbage transfer station, can solve problems such as easy emission of surrounding environment, worker injury, easy breeding of bacteria, etc., to ensure the safety and health of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

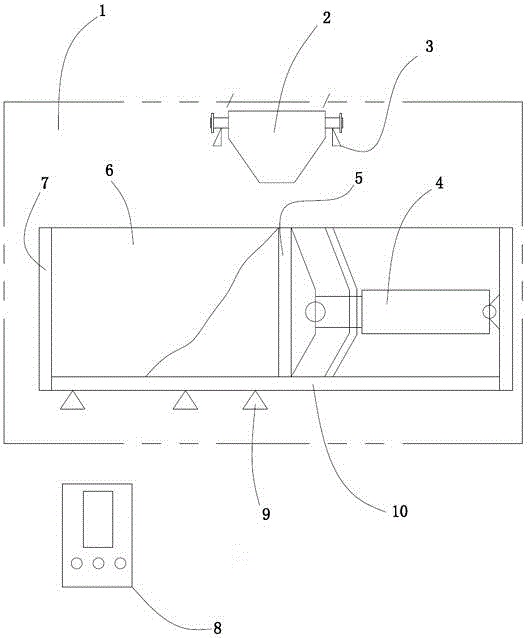

[0032]Embodiment 1: A compression system of a garbage transfer station is located in a closed space 1 as a whole, including a compressor system and a control system connected to the compressor system. The compressor system includes a compression channel 6, which is arranged at the compression channel feed The dump bucket 2, the push plate 5 arranged at the bottom 10 of the vertical compression channel in the compression channel, and the hydraulic cylinder 4 connected to the horizontal arrangement of the push plate (see the attached figure 1 ), the shape and size of the push plate match the shape and size of the compression channel. A movable baffle 7 is provided at the end of the compression channel to form a discharge port. The control system includes a controller 8 and various sensors connected to the controller. The sensors include a weight sensor 3 arranged on the dump bucket, a plurality of travel switches 9 arranged at the compression channel and a pressure sensor arrang...

Embodiment 2

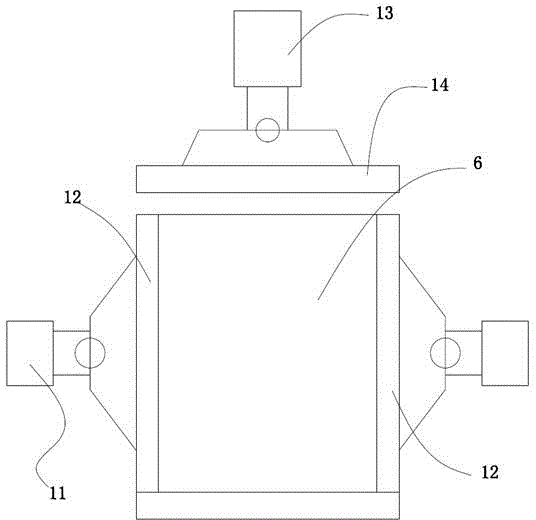

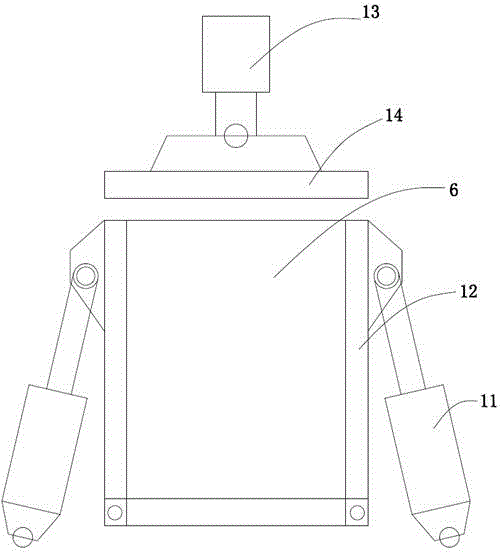

[0034] Embodiment 2: a kind of compression system of rubbish transfer station (see attached Figure 4 ), the two sides at the end of the compression channel are respectively provided with side push plates 12, the side push plates are connected with side hydraulic cylinders 11, the length of the side push plates is less than the length of the compression channel; the upper part of the end of the compression channel is provided with an upper push plate 14. The upper push plate is connected with the push down hydraulic cylinder 13, and the length of the upper push plate is less than the length of the compression channel. A travel switch 9 is set in front of the side push plate, a travel switch is set at 10 cm behind the boundary of the side push plate, and a travel switch is set at the end of the compression channel. The side push plate is horizontally movable, and the side hydraulic cylinder is arranged horizontally (see attached figure 2 ); or the lower side of the side push ...

Embodiment 3

[0039] Embodiment 3: a kind of compression system of garbage transfer station (see attached Figure 9 ), the feeding port of the compression channel is provided with a feeding belt, the feeding belt is connected with the tipping bucket, and both the feeding belt and the tipping bucket are in a closed space. The feeding belt is divided into two sections, which are respectively the front feeding belt 23 and the rear feeding belt 26. There is a garbage pretreatment pool 24 connected between the front feeding belt and the rear feeding belt. The pretreatment pool is provided with a turning bucket on the side of the rear feeding belt. 25. The rear feeding belt is docked with the turning bucket, and the lower part of the rear feeding belt is provided with a sewage receiving tank (not shown in the figure), and the sewage receiving tank is connected to the sewage treatment tank. The tipping bucket is provided with an infrared ray 27, and the infrared ray measures the volume of the garb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com