Subsea pipeline channel door-type block

A submarine pipeline and door-type technology, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problem that the concrete weight layer cannot be arranged at will, and achieve convenient adjustment of installation layout without affecting the environment. Elevation has no effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

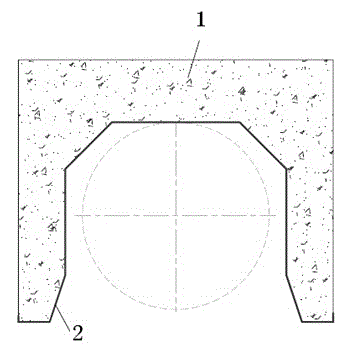

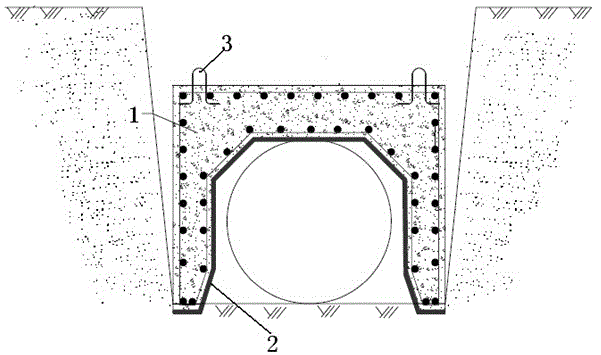

[0012] Such as figure 1 As shown, the door-shaped block in the submarine pipeline groove of the present invention includes a concrete briquette 1 and a rubber sheet 2 .

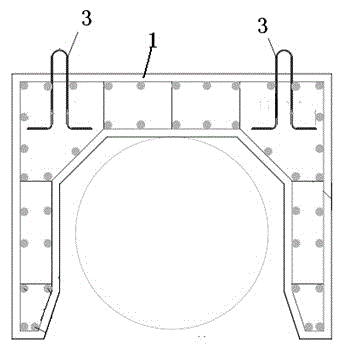

[0013] The concrete briquetting block 1 is provided with a groove, and a rubber sheet 2 is pasted on the wall of the groove. Both the width and height of the groove are greater than the diameter of the subsea pipeline. The upper end surface of the concrete briquette 1 is provided with lifting lugs 3 . The door block is made of concrete above C20, and can be properly reinforced to meet the hoisting requirements, that is, the durability requirements.

[0014] Such as figure 2 As shown, the concrete compact 1 is a reinforced concrete structure, and its cross-sectional size matches the cross-sectional size of the trench. The size of the door block is determined according to the secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com