Bearing lubricating system of coal mill

A bearing lubrication and lubrication system technology, applied in the direction of engine lubrication, lubricating parts, mechanical equipment, etc., can solve the problems of long running time of oil pumps, equipment affecting the environment, affecting safety production, etc., to save maintenance funds and operating costs, Good filtering effect, ensure healthy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

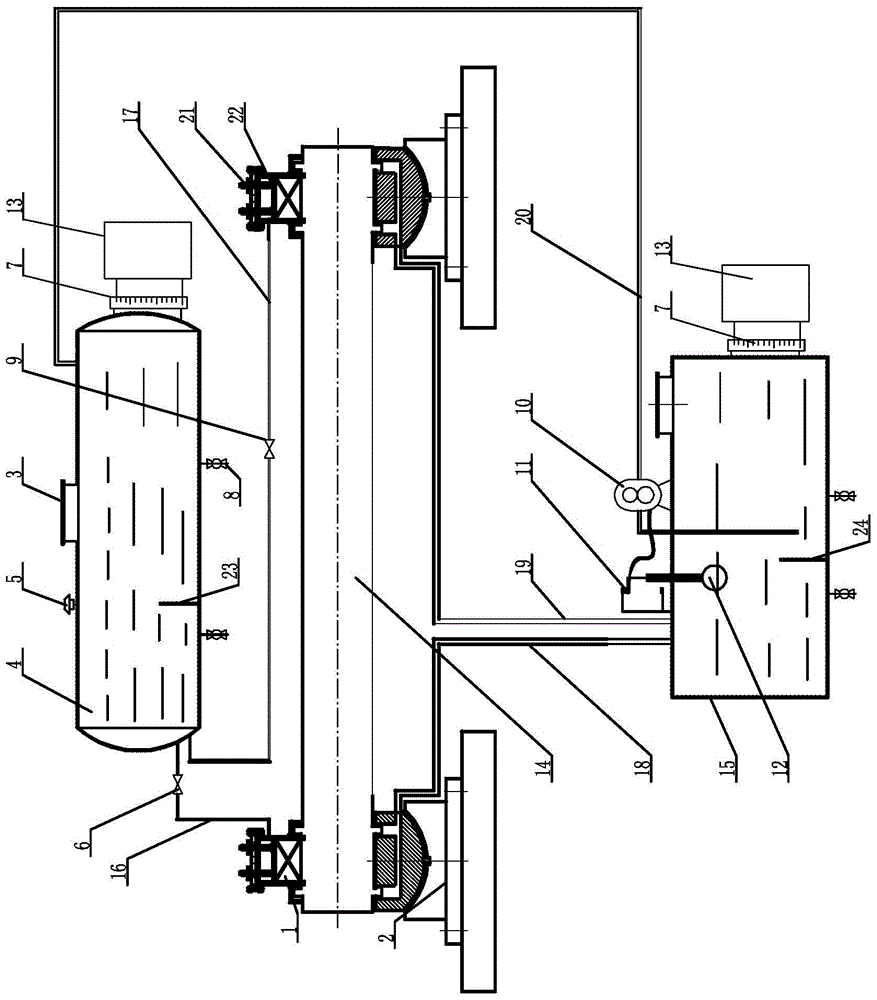

[0007] Specific implementation mode one: combine figure 1 Describe this embodiment, a coal mill bearing lubrication system described in this embodiment, the lubrication system includes a sponge body 1, a high oil tank 4, an oil pump 10, a limit contactor 11, a float 12, a shaft 14, and a low oil tank 15. The first oil inlet pipe 16, the second oil inlet pipe 17, the first oil outlet pipe 18, the second oil outlet pipe 19, the oil return pipe 20, the screw adjustment rod 21, the pressure plate 22, two bearing seats with bearings 2, two The liquid level gauge 7 and two liquid level control boxes 13, the top of the high oil tank 4 and the top of the low oil tank 15 are all processed with manholes 3, and the top of the bearing block 2 with bearings is provided with an oil storage tank, each oil storage tank There is a sponge body 1 inside, the screw adjustment rod 21 is fixed on the upper end surface of the pressure plate 22, the pressure plate 22 is set in the oil storage tank, a...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 Describe this embodiment, the coal mill bearing lubrication system described in this embodiment, the high oil tank 4 includes a first oil tank partition 23, the low oil tank 15 includes a second oil tank partition 24, the first oil tank partition 23 is vertical It is vertically arranged on the inner wall of the bottom of the high fuel tank 4, and the second fuel tank partition 24 is vertically arranged on the inner wall of the bottom of the low fuel tank 15. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 Describe this embodiment, a coal mill bearing lubrication system described in this embodiment, the lubrication system also includes four blowdown valves 8, two blowdown valves 8 are installed at the bottom of the high oil tank 4 and the low oil tank 15, other It is the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com